One-bath one-step dyeing method of PBT fiber/nylon fiber/silk blended fabric

A technology of nylon fiber and blended fabrics, applied in the field of textile printing and dyeing, can solve the problems of undiscovered dyeing method of PBT fiber/nylon fiber/silk blended fabrics, poor color matching between nylon fiber and silk, uneven coloring, etc., and achieve various durability The effect of excellent temperature, environmental friendliness and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

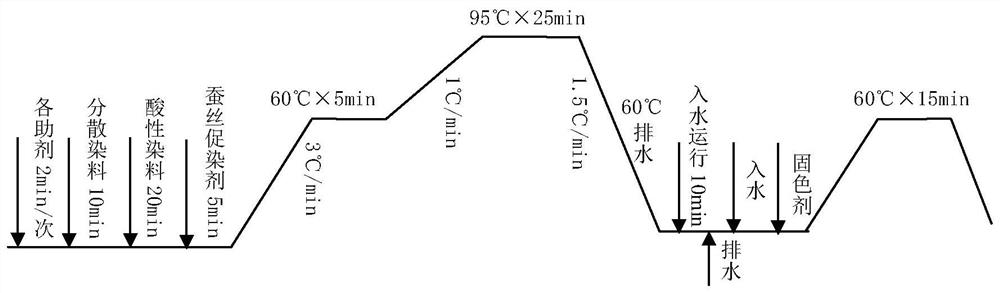

Embodiment 1)

[0040] The PBT fiber / nylon fiber / silk blended fabric of this embodiment is woven by PBT fiber / nylon fiber / silk blended yarn; in the PBT fiber / nylon fiber / silk blended yarn of this embodiment, PBT fiber and nylon fiber and The blending ratio of silk is 70%: 20%: 10%.

[0041] The one-bath and one-step dyeing method of the blended fabric is as follows:

[0042] ① Pretreatment.

[0043] Immerse PBT fiber / nylon fiber / silk blended fabric into 1.0g / L scouring emulsifier SEM-35N (from Shinshou Chemical Co., Ltd., whose main component is polyoxyethylene nonylphenol ether), 1.0g / L permeation In the scouring treatment solution of agent AMP800 (from Shanghai Dingxu Industry and Trade Co., Ltd., whose main component is fatty alcohol polyoxyethylene ether) and 2.0g / L soda ash, scouring treatment at 98°C for 30min.

[0044] Then wash with water once.

[0045] Then neutralize with glacial acetic acid to pH 7±0.1.

[0046] ②Dye the glacier mint color in one bath and one step.

[0047] Im...

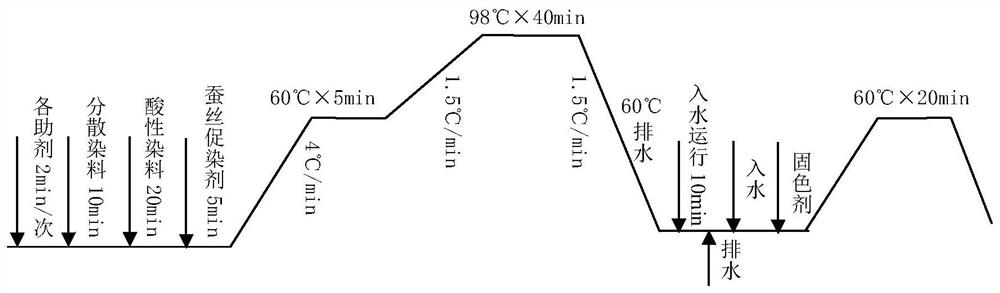

Embodiment 2)

[0059] The PBT fiber / nylon fiber / silk blended fabric of this embodiment is woven by PBT fiber / nylon fiber / silk blended yarn; in the PBT fiber / nylon fiber / silk blended yarn of this embodiment, PBT fiber and nylon fiber and The blending ratio of silk is 60%: 30%: 10%.

[0060] The one-bath and one-step dyeing method of the blended fabric is as follows:

[0061] ① Pretreatment.

[0062] Immerse the PBT fiber / nylon fiber / silk blended fabric into the scouring solution containing 1.0g / L scouring emulsifier SEM-35N, 1.0g / L penetrant AMP800 and 2.0g / L soda ash, and scouring at 95°C for 35 minutes.

[0063] Then wash with water once.

[0064] Then neutralize with glacial acetic acid to pH 7±0.1.

[0065] ②Dye royal blue in one bath and one step.

[0066] Immerse the PBT fiber / nylon fiber / silk blended fabric after the pretreatment in step ① into the dye solution containing disperse dyes and acid dyes, adjust the pH to 4.7±0.2 with glacial acetic acid, and first raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com