Low-temperature strong-heat air source heat pump system

A technology of hot air and source heat pumps, which is applied in climate sustainability, lighting and heating equipment, and compressors with reversible cycles, etc. It can solve problems such as high exhaust temperature, failure to start and run normally, and overheated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

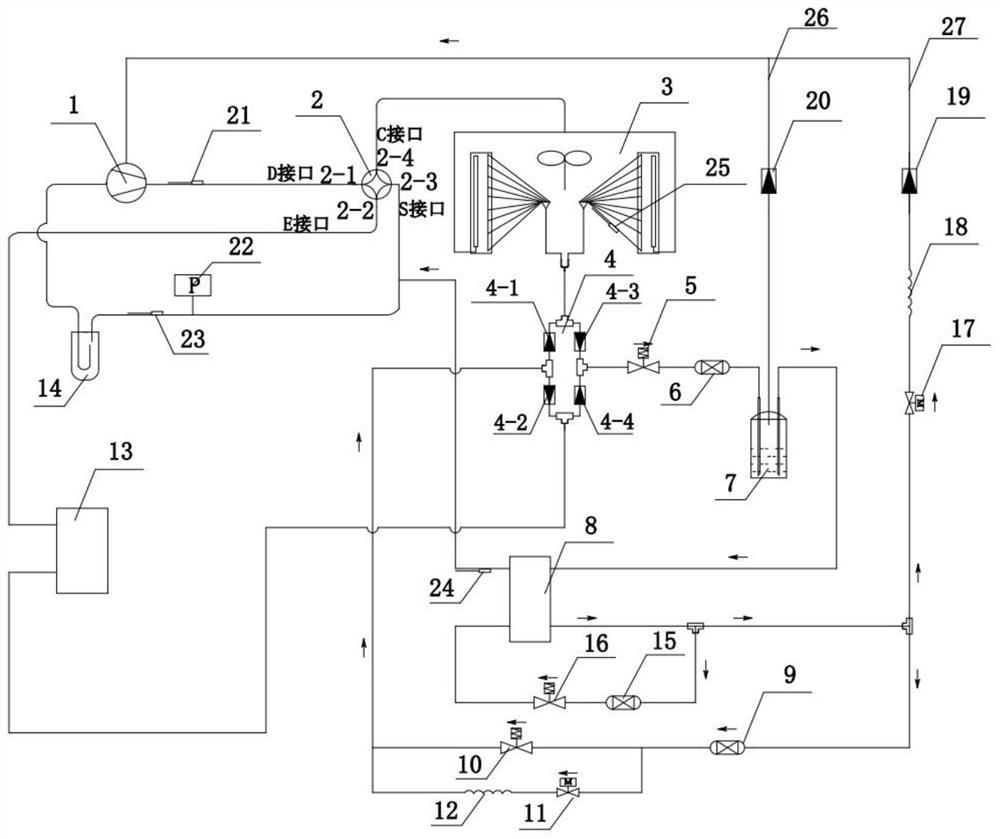

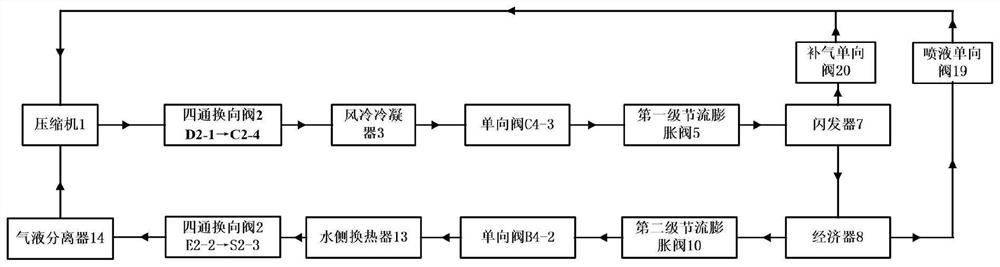

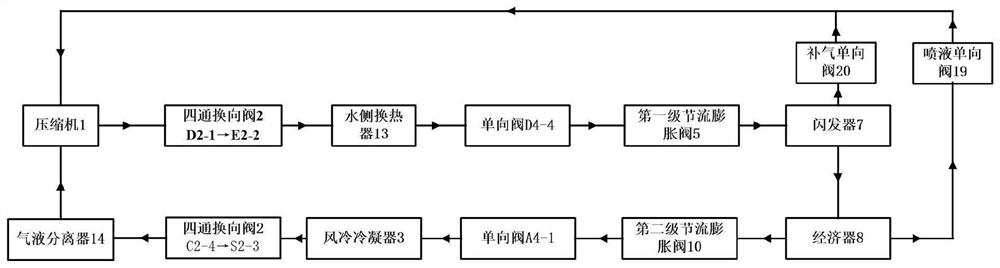

[0045] A kind of low temperature strong hot air source heat pump system (see Figure 1 to Figure 5 ), including compressor 1, four-way reversing valve 2, air-cooled condenser 3, check valve assembly 4, flasher 7, economizer 8, water side heat exchanger 13 and gas-liquid separator 14;

[0046] The suction port of the compressor 1 is connected to the gas-liquid separator 14, and the exhaust port is connected to the air-cooled condenser 3 or the water-side heat exchanger 13 through the D interface 2-1 of the four-way reversing valve 2. The air supply port of the compressor 1 is connected with the air supply circuit 26 and the liquid injection circuit 27; the coil of the compressor 1 is cooled by the suction working flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com