Ga2O3 film and preparation method thereof

A ga2o3 thin film technology, applied in the field of Ga2O3 thin film and its preparation, can solve the problems of long response time, low comprehensive performance of ultraviolet detectors, less research work, etc., and achieve the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

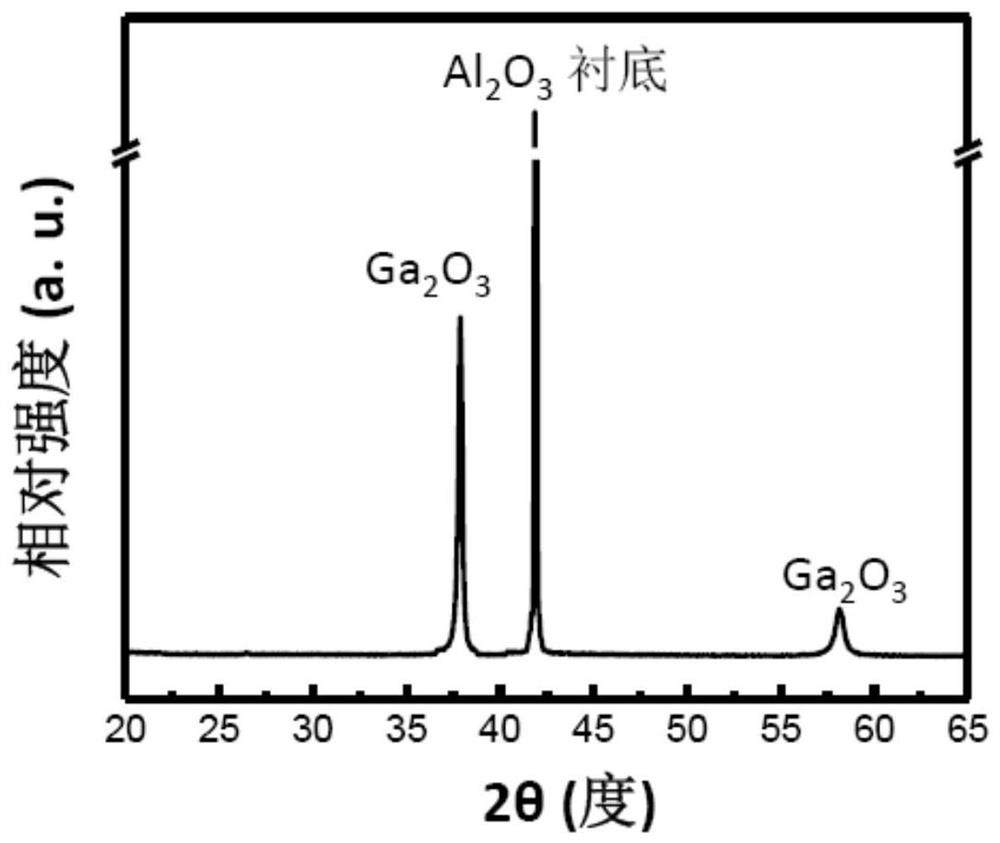

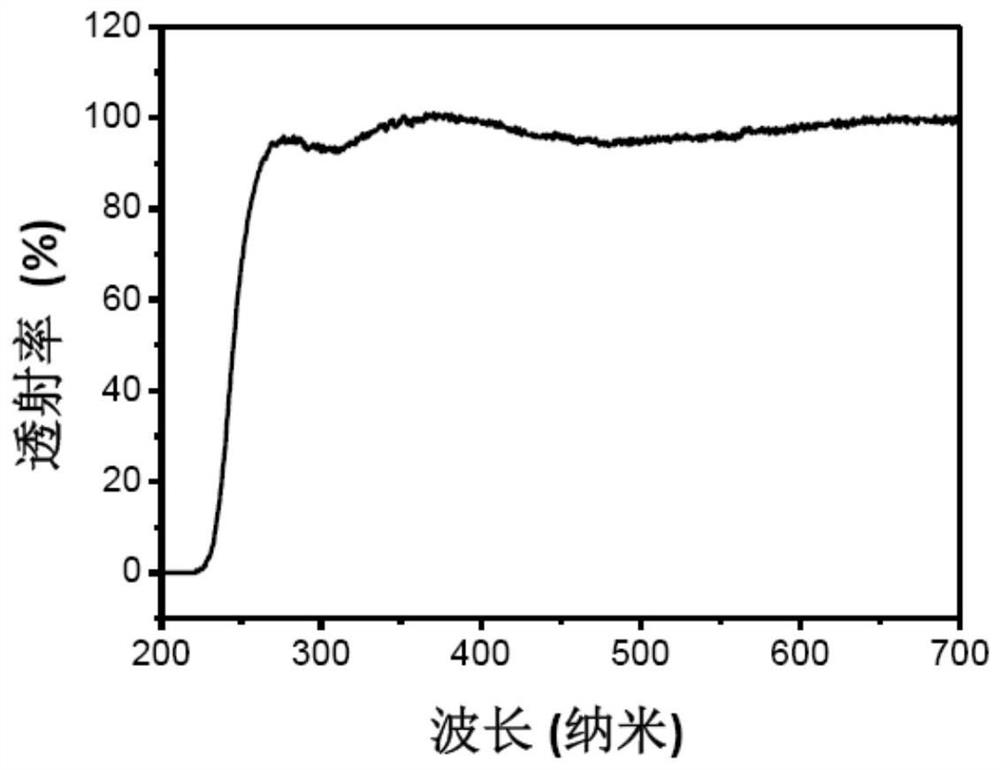

[0024] This application provides a Ga 2 o 3 The preparation method of the thin film by the chemical vapor deposition method in the metal organic compound on the Ga 2 o 3 The thin film is doped with a trace amount of magnesium, so that the thin film has high ultraviolet responsivity and short response time when applied to ultraviolet detectors. Specifically, the embodiment of the present invention discloses a Ga 2 o 3 The preparation method of thin film, comprises the following steps:

[0025] Using organic gallium compounds as the gallium source and high-purity oxygen as the oxygen source, metal-organic chemical vapor deposition is used to deposit on the surface of the substrate, and Ga is obtained after cooling down. 2 o 3 film;

[0026] in Ga 2 o 3 In the process of film growth, the organomagnesium compound is supplemented intermittently, and the time for supplementing the organomagnesium compound begins at Ga 2 o 3 0.1 to 6 hours after the film starts to grow, it...

Embodiment 1

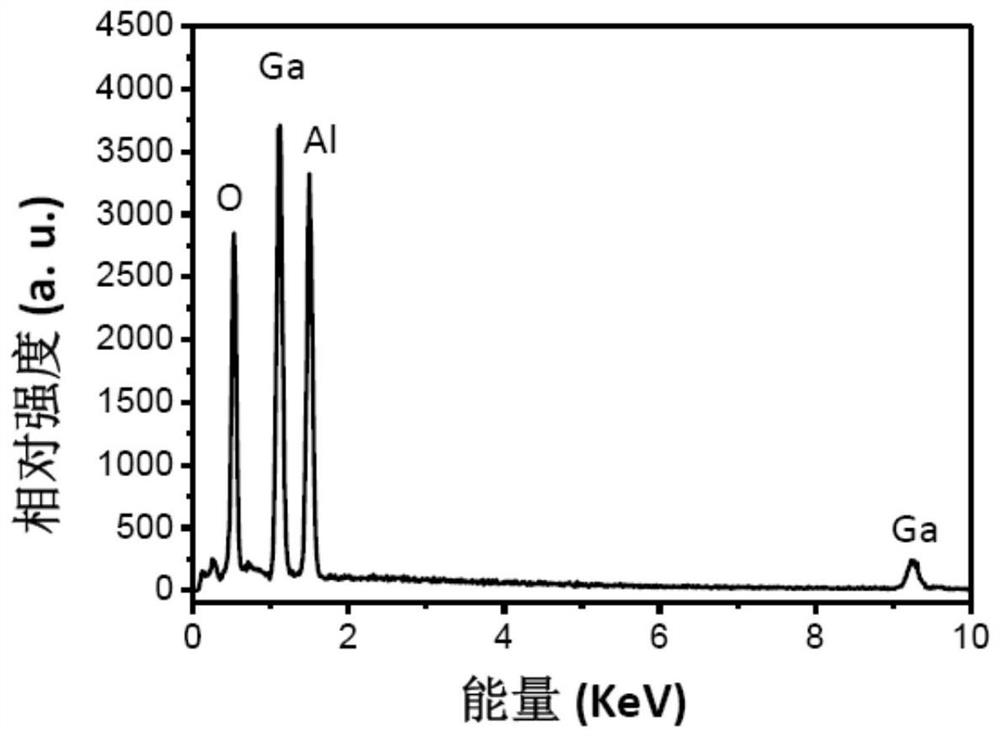

[0039] Put the cleaned sapphire substrate into the MOCVD growth chamber, turn on the molecular pump, and make the vacuum degree of the backside of the chamber reach within 100Pa; raise the substrate temperature to 1100°C, and after pretreatment for 0.5h, lower the temperature to growth The temperature is 800°C; nitrogen gas is introduced to make the vacuum degree of the chamber during the growth process 2×10 3 Pa;

[0040] Using trimethylgallium as the gallium source, the carrier gas flow rate of the gallium source is 25sccm, and the flow rate of the oxygen gas is 250sccm; during the growth process, dimethylmagnesocene is used as the magnesium source, and the magnesium source is turned on after 0.2h of growth, and the magnesium The carrier gas flow rate of the source is 4sccm, open the magnesium source for 30s, close for 120s, repeat twenty times, then stop adding the magnesium source;

[0041] The entire growth process lasted 2 hours (including the time of turning on the mag...

Embodiment 2

[0053] In order to verify the influence of the starting time of the magnesium source on the properties of the film, other conditions were the same as in Example 1 except that the starting time of the magnesium source was changed. The start-up times of samples numbered 2-1, 2-2, 2-3, and 2-4 are respectively 0.1h, 0.5h, 0.8h, and 1h (in Example 1, the magnesium source is turned on after starting growth for 0.2h);

[0054] After testing, it was found that the 4 groups of samples were Ga 2 o 3 The light absorption cut-off edge of the thin film is around 250nm. Except for a small amount of magnesium element detected in the EDS data of samples 2-4, no magnesium element was detected in other samples.

[0055] After the four groups of samples were prepared as ultraviolet detectors, except for sample 2-1, which had no obvious effect on the response time of the device, the response time of the device for other samples was significantly shortened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com