Wax pressing and wax injecting equipment for precision casting

A technology of precision casting and wax injection, which is applied in casting molding equipment, metal processing equipment, casting molds, etc. It can solve the problems of poor surface quality of wax molds, complicated process, and insufficient wax injection process, so as to reduce the difficulty of mold repair , the effect of novel shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

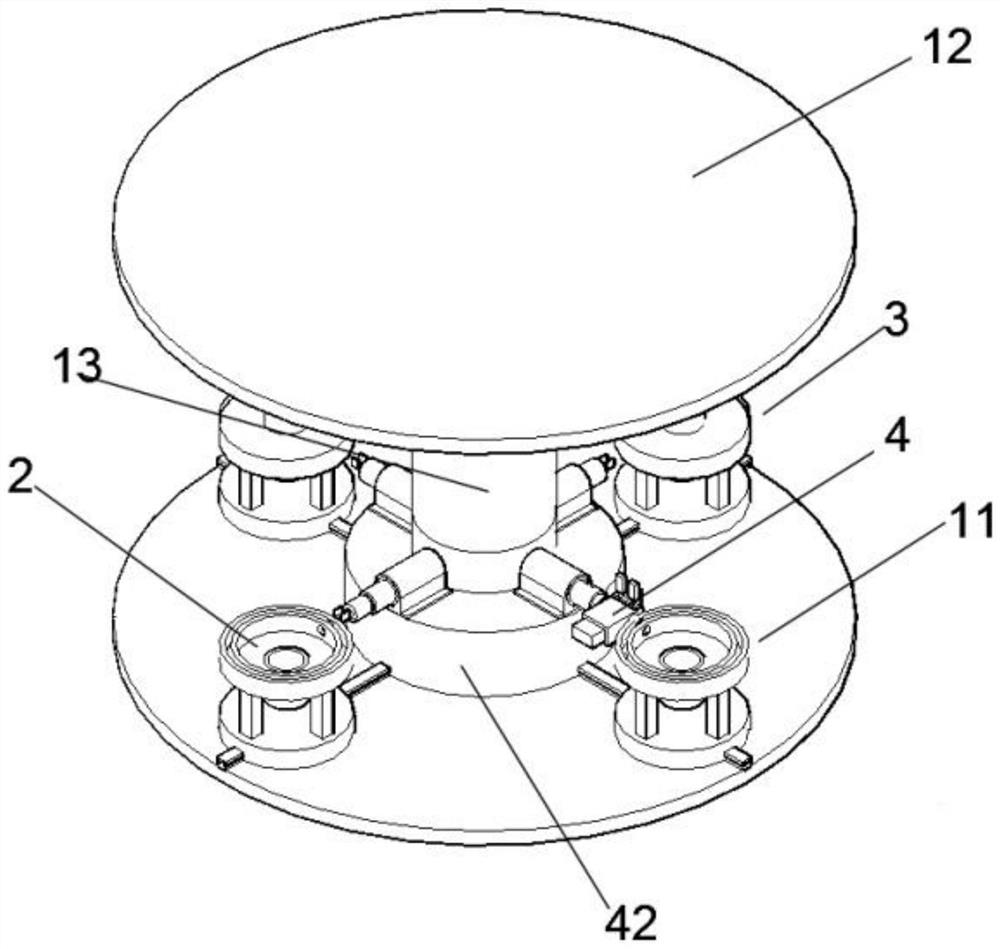

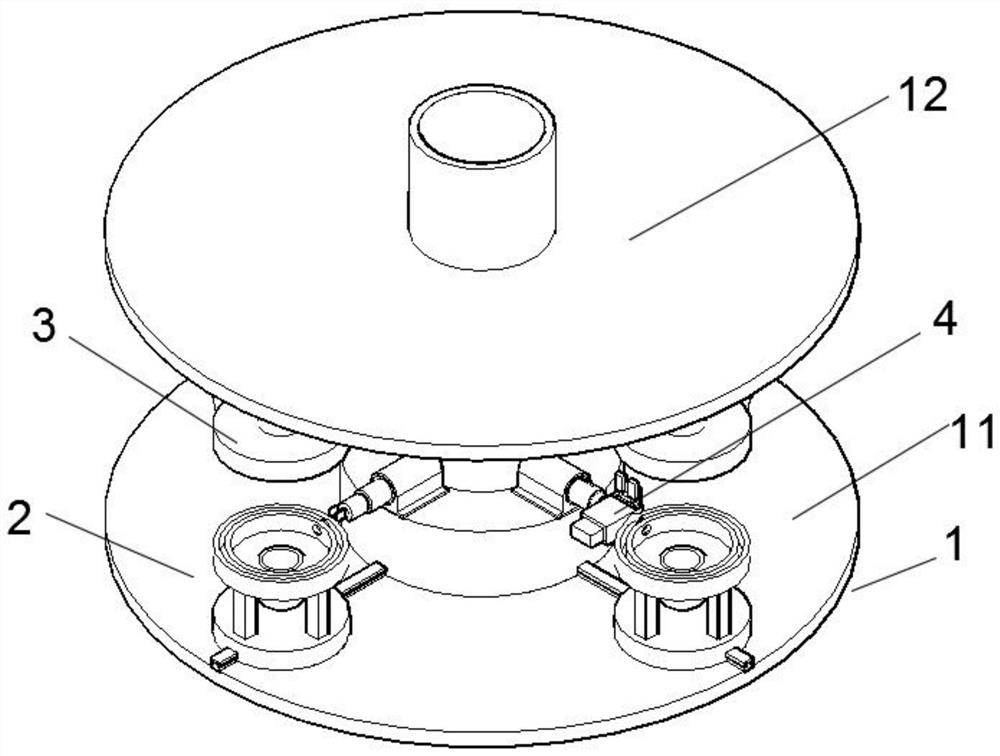

[0037] For specific embodiments, referring to the accompanying drawings, a precision casting wax injection equipment includes:

[0038] A base 1, the base includes a lower workbench 11 and an upper workbench 12, and a column 13 is connected between the upper workbench 12 and the lower workbench 11;

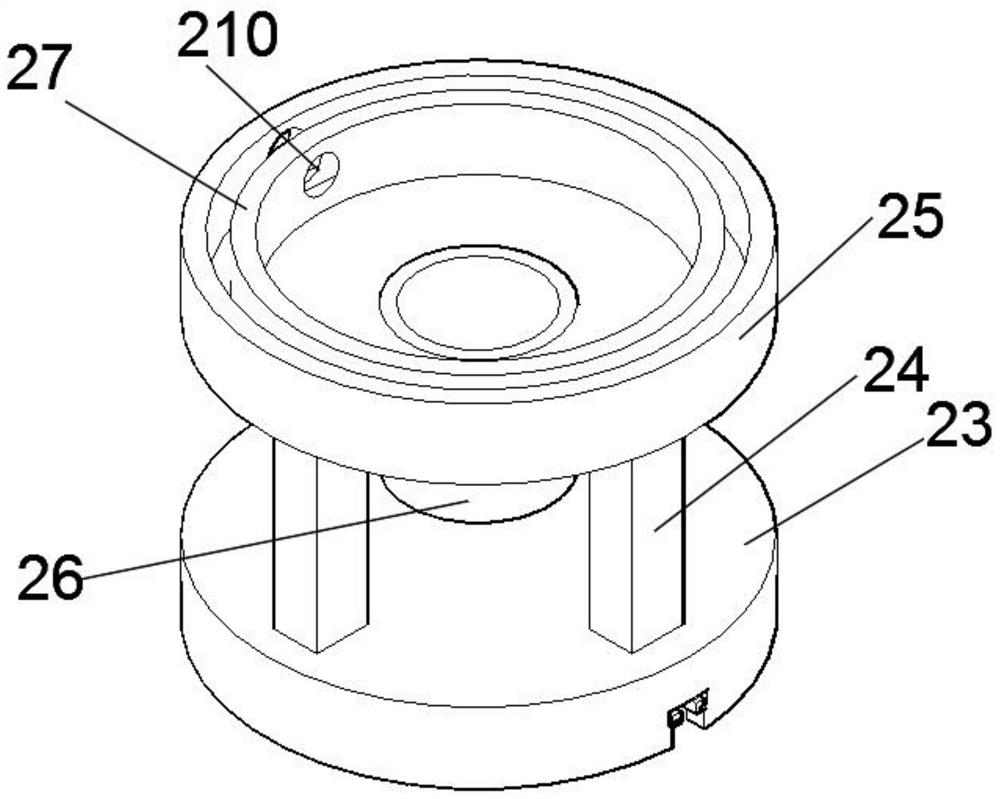

[0039] Lower die set 2, said lower die set 2 includes multiple sets of lower die bodies 21 evenly distributed on the upper surface of the lower workbench, each lower die body 21 is respectively movably connected with each sliding guide rail pair 22 on the upper surface of the lower workbench 11 , the lower mold body 21 includes a support platform 23, the support platform 23 is provided with a plurality of sets of poles 24, the top of each pole 24 is connected with the bottom of the lower protective shell 25, the lower protective shell 25 The bottom is provided with a servo motor 26, the output shaft end of the servo motor 26 passes through the lower protective shell 25 and is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com