Carton capable of preserving heat, preventing damp and refrigerating and high in pressure resistance

A technology of carton and anti-pressure layer, which is applied in the directions of thermal insulation containers, containers to prevent rot, and containers to prevent mechanical damage, etc. It can solve the problems of easy cracking and crushing, weak compression resistance of cartons, and low pressure, and achieve good thermal insulation performance and thermal insulation properties, good thermal insulation, and improved compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

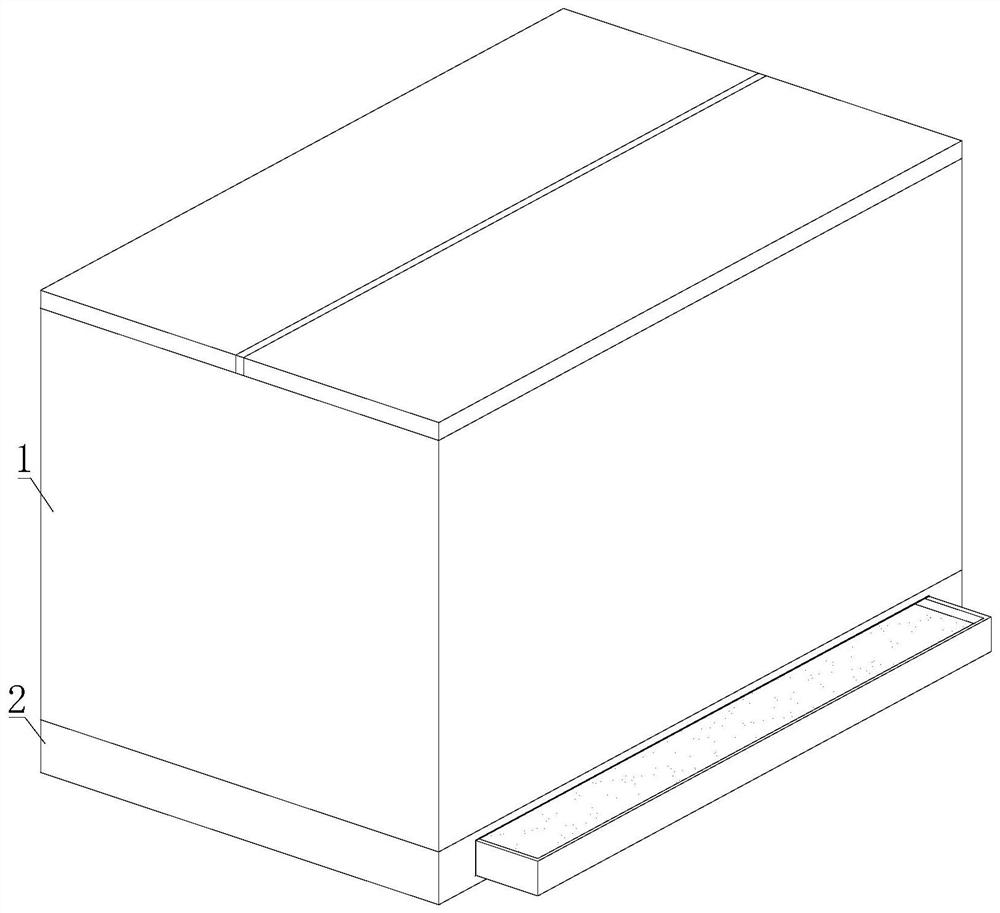

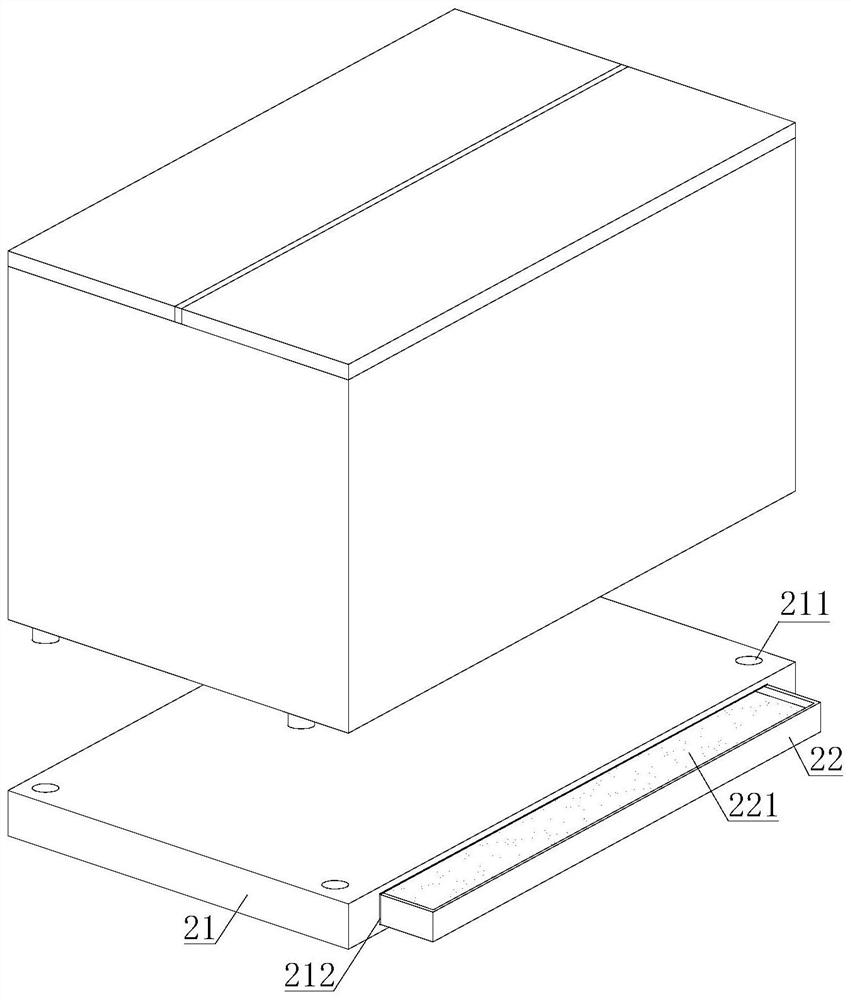

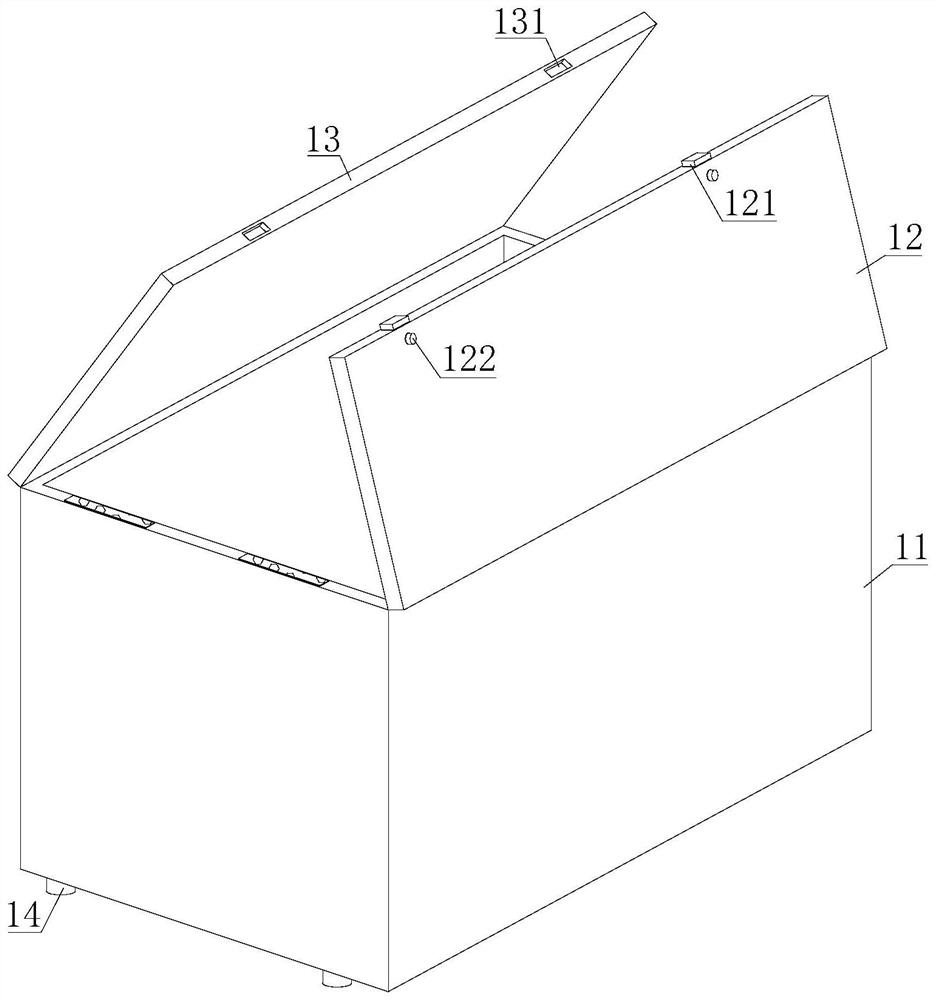

[0030] refer to figure 1 and 3 , a carton that can keep warm, moisture-proof, refrigerated, and compressive. It includes a main body 1 and an auxiliary body 2. The lower end of the main body 1 is provided with an auxiliary body 2. The main body 1 includes a box body 11, a movable cover A12, a movable cover B13 and a plug. Block 14, the upper end of the box body 11 is provided with a movable cover A12 and a movable cover B13, the lower bottom surface of the box body 11 is fixedly installed with an insert block 14, and the lower end of the box body 11 is provided with an auxiliary mechanism 2, and the auxiliary mechanism 2 includes a base 21 With the movable inner box 22, the inside of the base 21 is provided with a movable inner box 22, and the movable inner box 22 is movably connected with the base 21.

Embodiment 2

[0032] refer to Figure 4 and 5 , the box body 11 includes a mounting plate A111, a mounting plate B112, a bottom plate 113, a kraft paper layer 114, a foam layer 115 and a shaping layer 116. Both ends of the mounting plate A111 are provided with a mounting plate B112, and the mounting plate A111 and the mounting plate B112 are formed Closed rectangle, bottom plate 113 is set on the lower end of mounting plate A111 and mounting plate B112, kraft paper layer 114 is set on the outer surface of box body 11, foam layer 115 is set inside box body 11, shaping layer 116 is set on box body On the inner wall of 11, slide bars 1111 are provided on both sides of the mounting plate A111, a connecting groove 1121 is provided on one side of the mounting plate B112, and a sealing gasket 1122 is provided on the upper surface of the mounting plate B112, and the mounting plate A111 passes through the sliding bar 1111 and The connecting groove 1121 is connected with the mounting board B112.

Embodiment 3

[0034] refer to image 3 and 6, one side of the movable cover A12 is provided with a movable block 121, the outer surface of the movable cover A12 is provided with a rotary switch 122, the rotary switch 122 is movably connected with the movable block 121, and one side of the movable cover B13 is provided with a card slot 131, and the movable cover A12 is movably connected with the movable cover B13 through the movable block 121 and the card slot 131. The inside of the kraft paper layer 114 is provided with a sunscreen layer 1141, a pressure-resistant layer 1142 and a waterproof layer 1143. The sunscreen layer 1141 is arranged on the outside of the pressure-resistant layer 1142. The layer 1142 is arranged on the outside of the waterproof layer 1143, the sun-proof layer 1141 is a combination of sun-proof ceramic fiber and polyester fiber, and the pressure-resistant layer 1142 is filled with airbags.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com