A post-processing process for the preparation and molding of twisted fabrics

A post-processing and post-processing device technology, which is applied in the direction of fabric elongation, fabric surface trimming, heating/cooling fabric, etc. It can solve problems such as wear or pulling, temperature, etc. cannot be controlled effectively synchronously, and fabric cannot be stretched back. , to reduce the probability of shrinkage, improve the effect and speed, and avoid irreversible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways that are predetermined and covered by the claims.

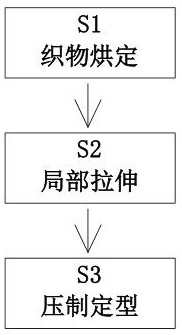

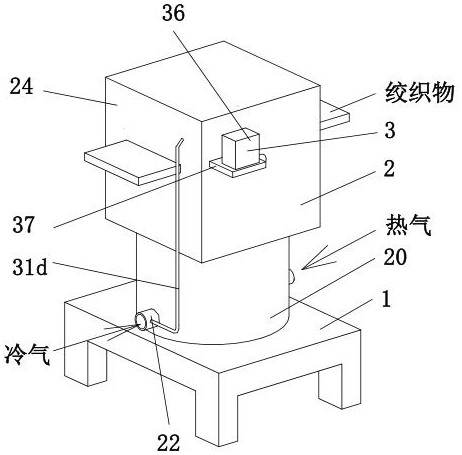

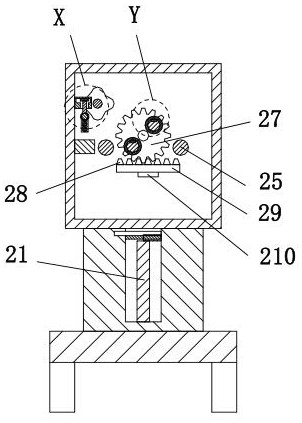

[0037] like Figure 1 to Figure 10 As shown, a twisted fabric preparation and molding post-treatment process uses a twisted fabric preparation and molding post-processing device. The twisted fabric preparation and molding post-processing device includes a workbench 1, a stretching mechanism 2 and a pressing mechanism 3. The specific treatment process when the twisted fabric preparation and molding post-processing device performs the twisted fabric preparation and molding post-processing is as follows:

[0038] S1. Fabric drying: enter cold air and hot air into the gas chamber 20 through the vent pipes 22 at the left and right ends of the gas chamber 20, and the cold air and hot air are fused in the extension pipe 23 to form hot and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com