Microchip integrated explosive foil detonator based on planar high-voltage switch

A high-voltage switch and explosive foil technology, which is applied in blasting barrels, weapon accessories, offensive equipment, etc., can solve problems that have not yet been seen, and achieve the effects of reducing ignition energy, broadening the application range, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

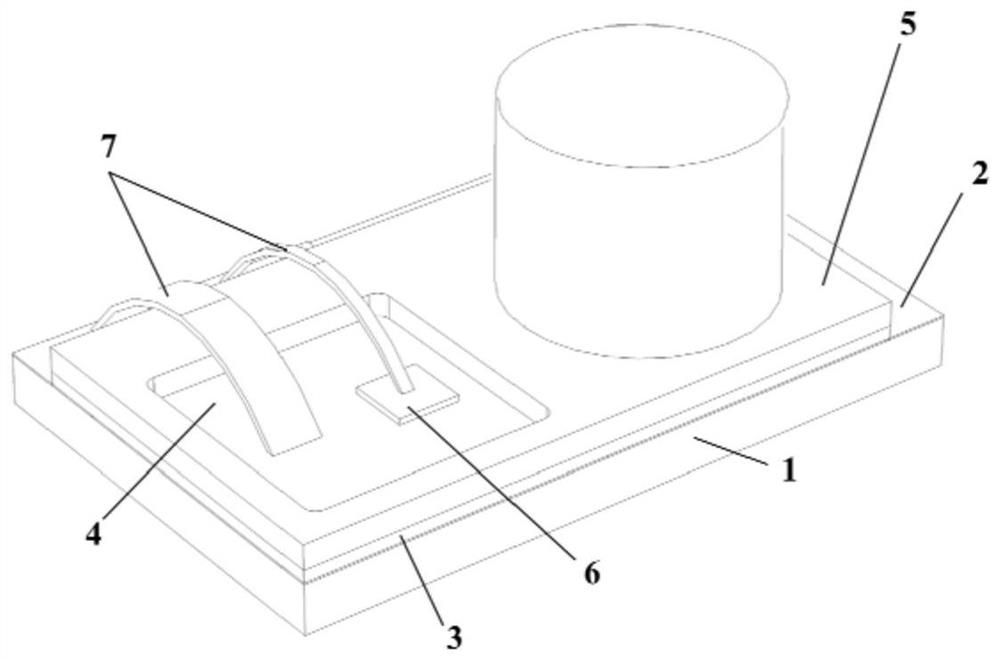

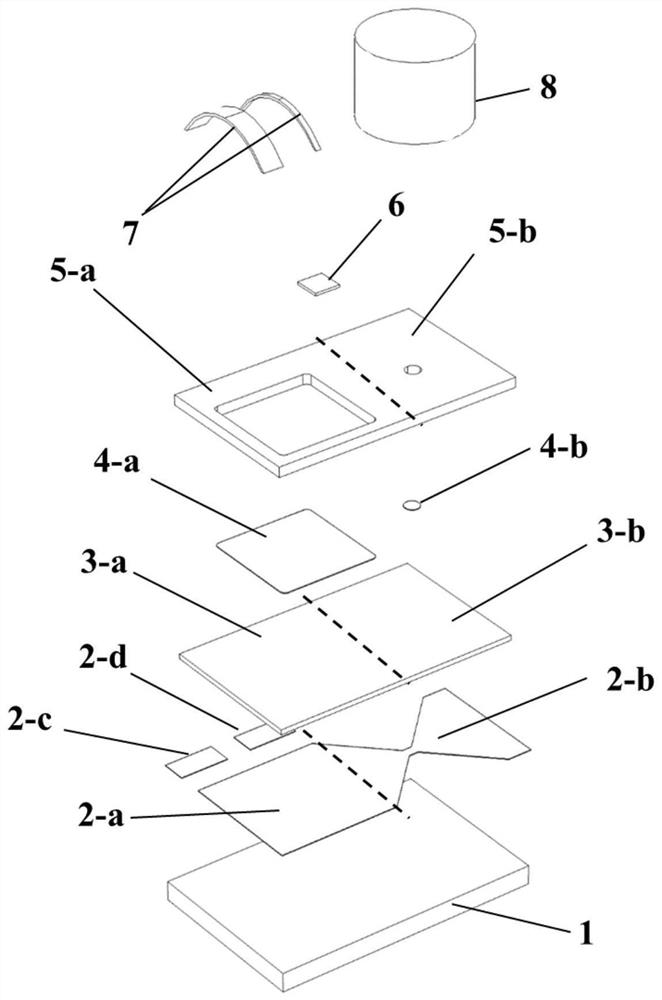

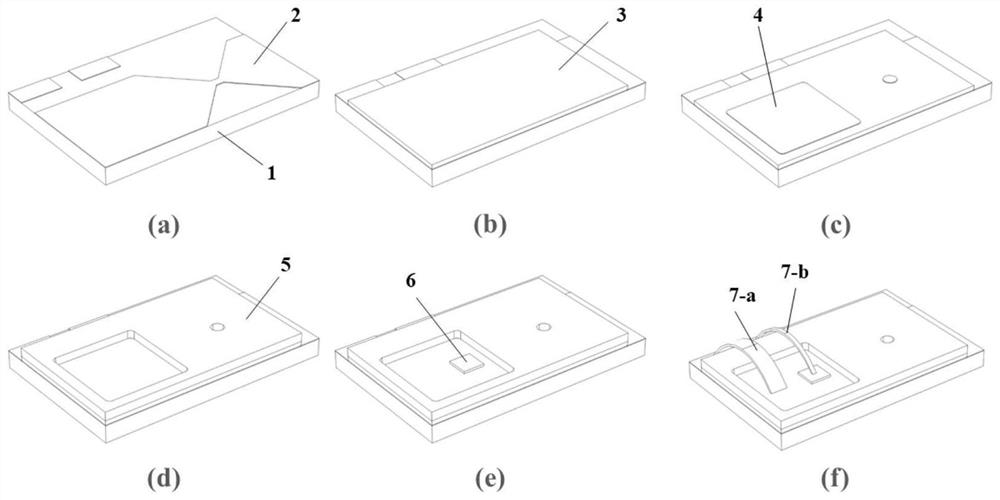

[0025] combine figure 1 , 2 , 3, the present embodiment has prepared a kind of microchip integrated explosive foil detonator based on planar high-voltage switch, and described chip comprises ceramic substrate 1, metal layer one 2, insulation layer 3, metal layer two 4, photoresist layer 5. Diode 6, metal welding strip 7 and explosive column 8. Using the magnetron sputtering deposition process, combined with the ultraviolet lithography technology, the metal layer 12 is prepared, and its film system is a W-Ti / Cu layer with a thickness of 50nm / 5μm, which is placed on the ceramic substrate 1, and the metal layer 12 The side of the planar high voltage switch is used as the lower electrode 2-a, and the side of the explosive foil initiator is used as the explosive foil 2-b. The size of the explosive foil is 600μm×600μm, and the other two "islands" are used as pads 1-2-c and Pad 2 2-d; Prepare an insulating layer 3 with a thickness of 50 μm by chemical vapor deposition, and place it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com