Optical isolator and laser

An optical isolator and isolation structure technology, applied in the field of optical isolation, can solve the problems of the complex structure of the collimated light output optical isolator, the limited use occasion and scope of the optical isolator, and the large overall size, etc., so as to reduce the material and production costs. , reduce the volume, overcome the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

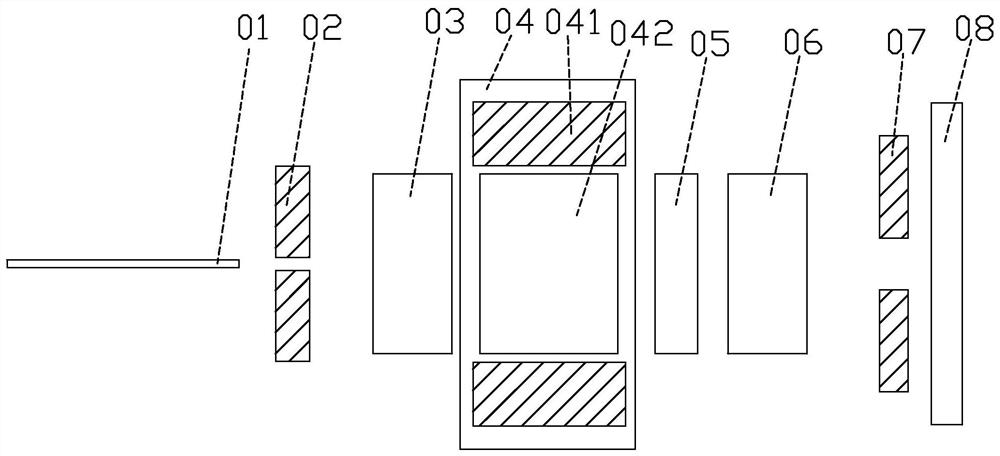

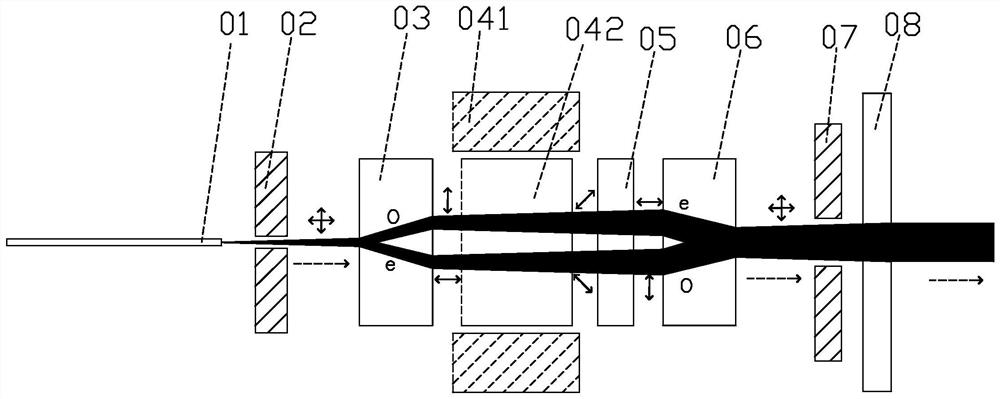

[0025] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of an optical isolator in the present invention; the optical isolator includes a divergence angle adjustment module 01 for adjusting the beam divergence angle, a beam isolation structure and a collimating lens 08 arranged along the forward optical path direction, In this embodiment, the beam isolation structure includes a first diaphragm 02, a first dichroic crystal 03, a magneto-optical rotation device 04, a phase rotation crystal 05, a second dichroic crystal 06, and a second diaphragm 07 arranged along the direction of the optical path. Specifically, the magneto-optical rotation device 04 includes a magnetic tube 041 and an optical rotation crystal 042, and the phase rotation crystal 05 can be realized by using a half-wave plate or a quartz optical rotation rod. In addition, in this embodiment, the divergence angle adjustment module 01 is a beam expanding fiber, which expands ...

Embodiment 2

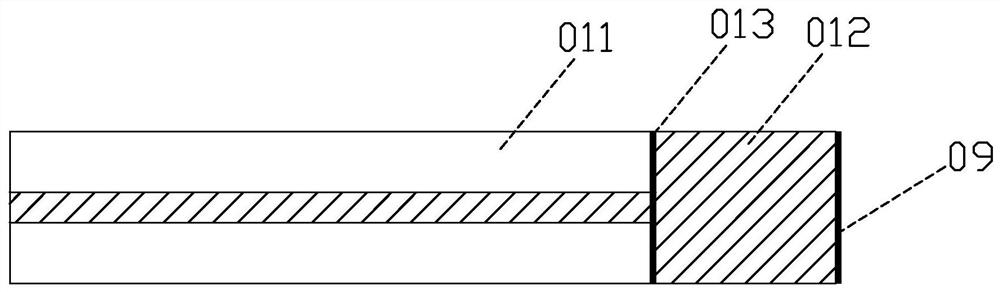

[0030] refer to figure 1 , in this embodiment, when the user uses an optical fiber with a relatively large divergence angle to introduce the beam, the divergence angle adjustment module 01 is realized by using an expanded core fiber, and the expanded core fiber is to reduce the input beam (with a large beam divergence angle). Small divergence angle processing to reduce the divergence angle of the original input beam. refer to Figure 5 , Figure 5 It is a schematic diagram of a specific embodiment of the core-expanded optical fiber of an optical isolator in the present invention. The core-expanded optical fiber 014 is obtained by thermally expanding the core at one end of the optical fiber, and the divergence angle of the optical fiber is reduced by increasing the core diameter of the optical fiber. . Similar to Embodiment 1, an anti-reflection film 09 is coated on the end face of the expanded-core optical fiber 014 as an anti-reflection structure. The optical path structu...

Embodiment 3

[0032] refer to figure 1 , in this embodiment, when the user uses an optical fiber with a relatively large divergence angle to introduce the light beam, the divergence angle adjustment module 01 is realized by using a graded-index fiber. The divergence angle reduction process is performed to reduce the divergence angle of the original input beam. Specifically, refer to Figure 6 , Figure 6 It is a schematic diagram of a specific embodiment of a graded-index optical fiber of an optical isolator in the present invention. In actual use, a section of graded-index optical fiber 015 can be welded at one end of the optical fiber 011. The fusion point is as follows Figure 6 013 in. The divergence angle of the beam can be changed by controlling the length of the graded-index fiber 015. For the specific structure of the graded-index fiber 015, see Figure 7 , including cladding 0151 and core 0152, graded index fiber is also called self-focusing fiber, refer to Figure 8 , Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com