TC-SAW device and manufacturing method thereof

A TC-SAW, manufacturing method technology, applied in electrical components, impedance networks, etc., can solve the problems of insufficiency, frequency drift, overall performance deterioration, etc., to achieve the effect of frequency stability, high Q value, and easy peeling

Pending Publication Date: 2020-09-29

SHENZHEN MICROGATE TECH

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For duplexer frequency bands (such as Band2, 3, 8, 25, 26) with very narrow frequency intervals between the transmitting end and the receiving end, the frequency drifts and the overall performance deteriorates under long-term load power operation, which cannot meet the needs of modern mobile communications. needs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0085] Such as Figure 10 Shown is a measured temperature coefficient diagram of a TC-SAW device. It can be seen from the figure that its temperature coefficient is -15.8 ppm / K.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

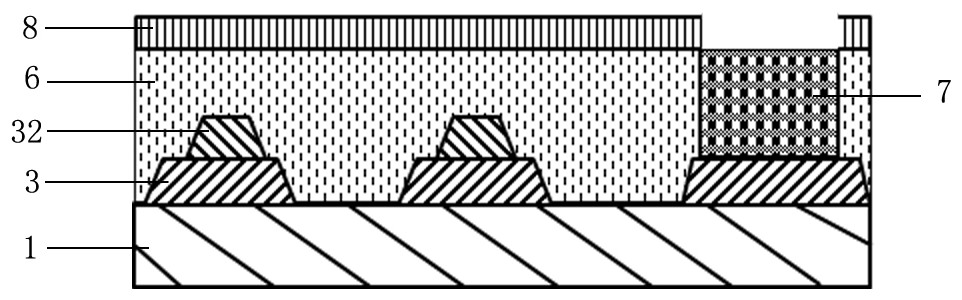

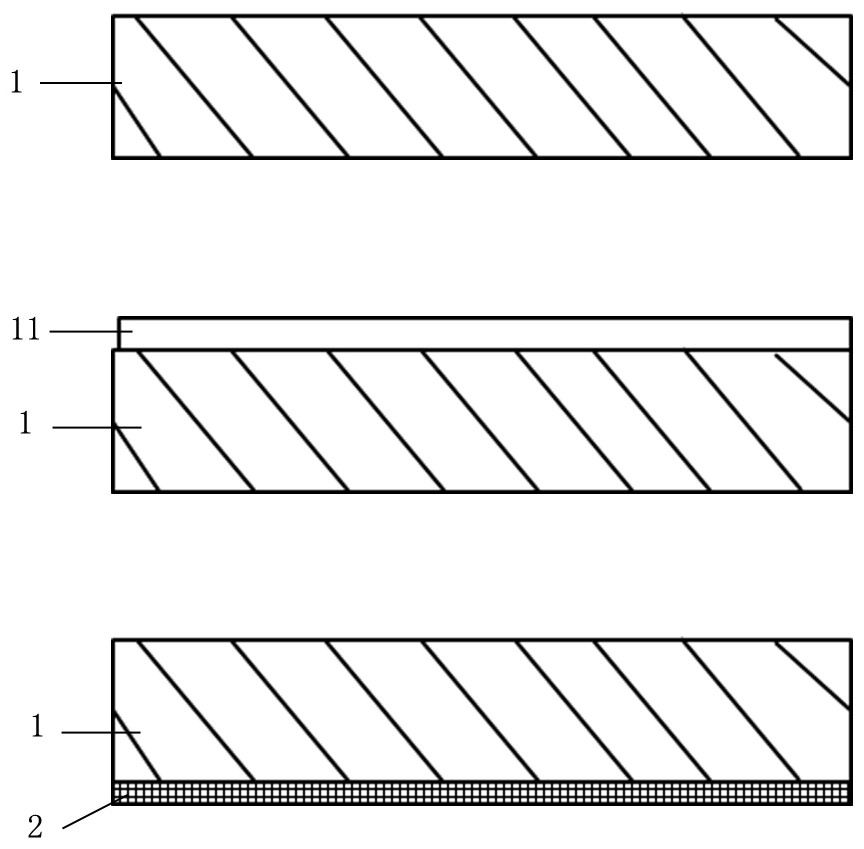

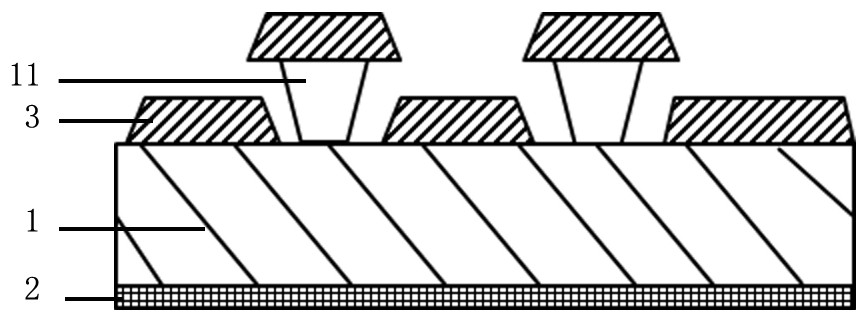

The invention relates to the field of surface acoustic wave devices. A conventional STD-SAW device is very sensitive to temperature change, and performance change is relatively obvious. Therefore, theinvention provides a TC-SAW device, which comprises a piezoelectric material substrate, an interdigital electrode arranged on the piezoelectric material substrate, a temperature compensation layer covering the interdigital electrode, a third metal PAD layer on the piezoelectric material substrate and a passivation layer on the outermost layer. A manufacturing method comprises the following steps:coating a photoresist layer, depositing a metal film, depositing a first layer of interdigital electrode layer, depositing a second layer of electrode, depositing a temperature compensation material,and depositing a passivation layer for isolating air and the like. The temperature coefficient of the TC-SAW device can reach 0 ppm / K to-25 ppm / K, frequency stability is improved, the Q value is improved, and high requirement of mobile communication equipment can be met; the manufacturing method can be used for manufacturing resonators, filters, duplexers and other elements and is wide in application.

Description

technical field [0001] The invention relates to a surface acoustic wave device chip, in particular to a TC-SAW device and a manufacturing method thereof. Background technique [0002] With the rapid development of mobile communication technology, it has developed from the initial 2G to 3G, and then to today's 4G. It is believed that we will enter the 5G era in the near future. Handheld terminal devices have more and more functions and more and more frequency bands. Such as: GSM, TD_SCDMA, WCDMA, TDD_LTE, FDD_LTE and GPS, Bluetooth, WiFi and other different functions combined in one product. This also poses challenges to design and mass production. Frequency resources are becoming more and more crowded, and the guard interval between frequency bands of different communication systems is getting smaller and smaller. On the one hand, this puts stricter requirements on the frequency spectrum and power of the transmitting end of each system, ensuring that the transmitted signal...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H03H9/02H03H9/145

CPCH03H9/02543H03H9/02622H03H9/02834H03H9/02984H03H9/14502H03H9/14541H03H9/145H03H9/02

Inventor 宋崇希姚艳龙

Owner SHENZHEN MICROGATE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com