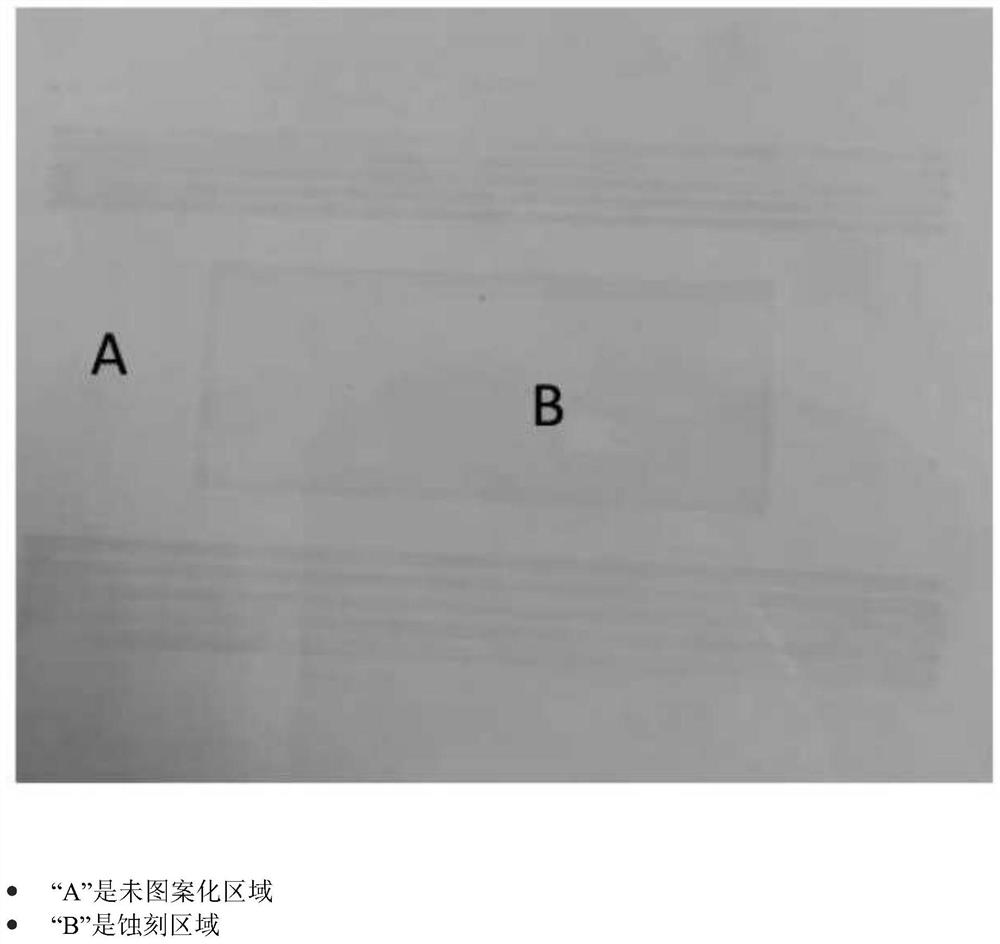

Patterning paste

A technology of paste paste and patterning, applied in chemical/electrolytic methods to remove conductive materials, instruments, inks, etc., can solve the problem of slowing down the processing time of silver nanowire films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

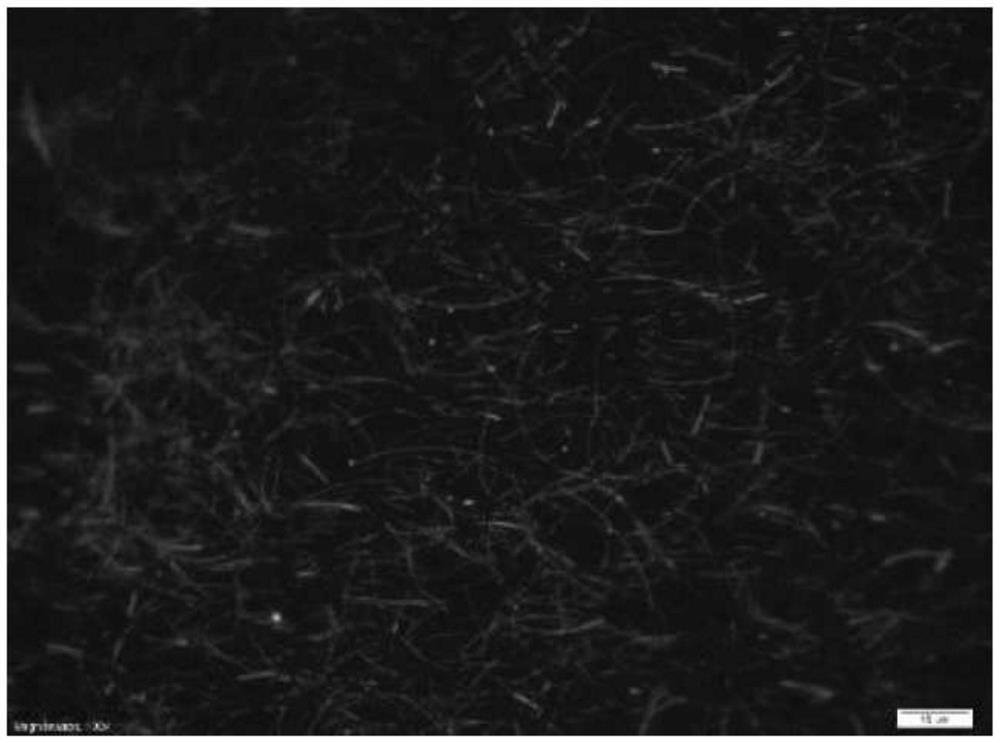

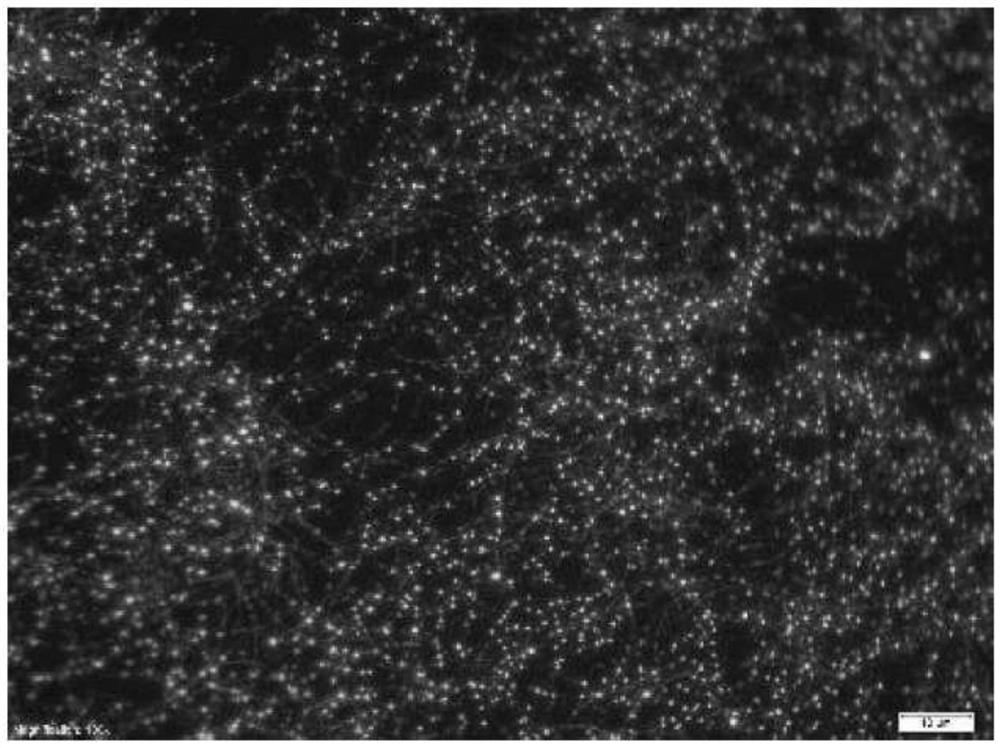

Image

Examples

example

[0060] The following examples are presented to demonstrate the general principles of the invention. The invention should not be considered limited to the particular examples presented. All parts and percentages in the examples are by weight unless otherwise indicated.

example 1

[0062] A patterning paste was prepared by adding 7.24 grams of deionized water and 28.96 grams of ethylene glycol to a 10 oz polypropylene container equipped with a stirrer. 4.24 grams of 2-hydroxyethylcellulose (HEC) (viscosity average molecular weight (Mv) ~ 90,000) was incorporated by means of a stirrer. After the HEC was dissolved, 10 grams of guanidinium thiocyanate was incorporated by means of a stirrer and mixed until dissolved. After the guanidine thiocyanate had dissolved, 0.25 g of SULFOPON 30S03 was mixed in. After adding SULFOPON 30S03, directly mix in 0.57 g of TEGO Airex 902W. 48.74 grams of BLANC FIXE MICRO (barium sulfate) were mixed in until a uniform dispersion of the mixture was observed. The material was then moved to and processed through a three-roll mill and placed into new 10 oz polypropylene containers.

[0063] Table 1

[0064] components weight / gram) Deionized water 7.24 Ethylene glycol 1

28.96 2-Hydroxyethylcell...

example 2

[0072] A patterned paste material was prepared by adding 7.65 grams of deionized water and 30.58 grams of ethylene glycol to a 10 oz polypropylene container equipped with a stirrer. 4.48 grams of 2-hydroxyethylcellulose (HEC) (viscosity average molecular weight (Mv) ~ 90,000) were incorporated by means of a stirrer. After the HEC was dissolved, 4.97 grams of guanidinium thiocyanate was incorporated by means of a stirrer and mixed until dissolved. After the guanidine thiocyanate was dissolved, 0.26 grams of DYNAX DX4005N was mixed in. After adding DYNAX DX4005N, directly mix in 0.60 g of TEGOAirex 902W. 51.47 grams of BLANC FIXE MICRO (barium sulfate) were mixed in until a uniform dispersion of the mixture was observed. The material was then moved to and processed through a three-roll mill and placed into new 10 oz polypropylene containers.

[0073] Table 2

[0074]

[0075]

[0076] 7 Wetting and leveling additives commercially available from Dynax Corporation (Poun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com