Gradient porous material and preparation method thereof, atomizer and electronic atomization device

A gradient porous and atomizer technology, which is used in transportation and packaging, ceramic products, other household appliances, etc., can solve the problem of poor bonding performance of porous materials at both ends of the interface, affecting the service life of gradient porous materials, and poor interface connection. Natural and other problems, to achieve the effect of small firing shrinkage, low cost, and easy automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] One embodiment of the present invention provides a method for preparing a gradient porous material, the method comprising the following steps:

[0030] Step a. The raw materials of each functional layer are made into corresponding slurries, wherein the slurries of at least two functional layers are made of different raw materials.

[0031] Step b. Spray-dry the slurry of each functional layer respectively to make dry granulated powder of each functional layer.

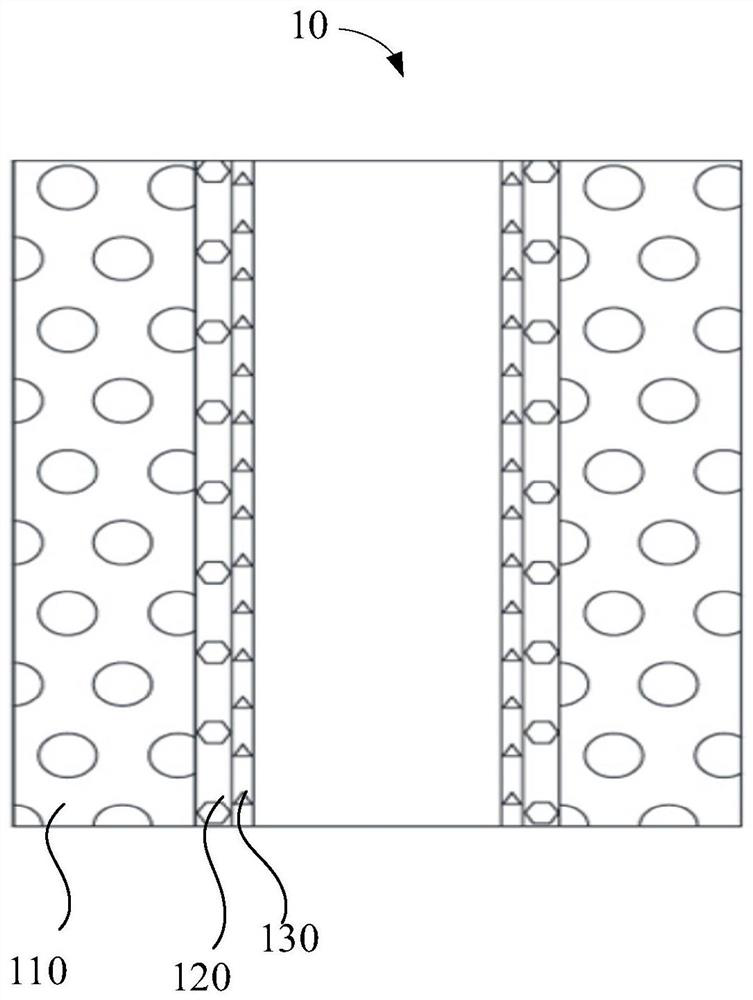

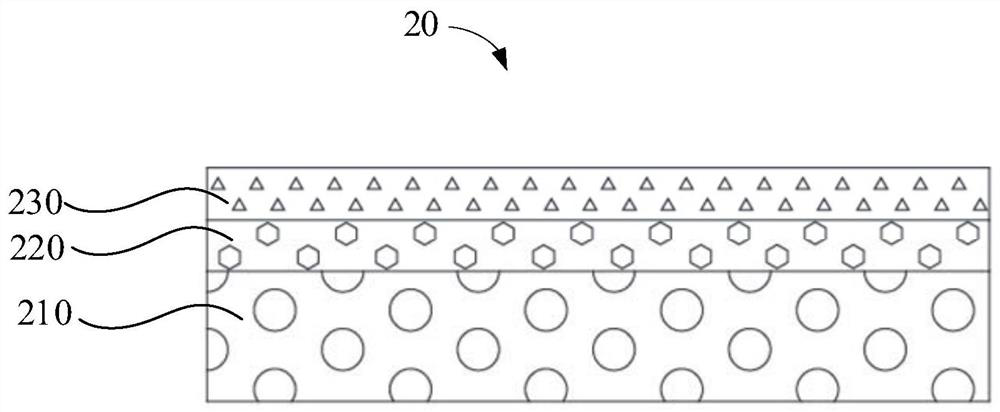

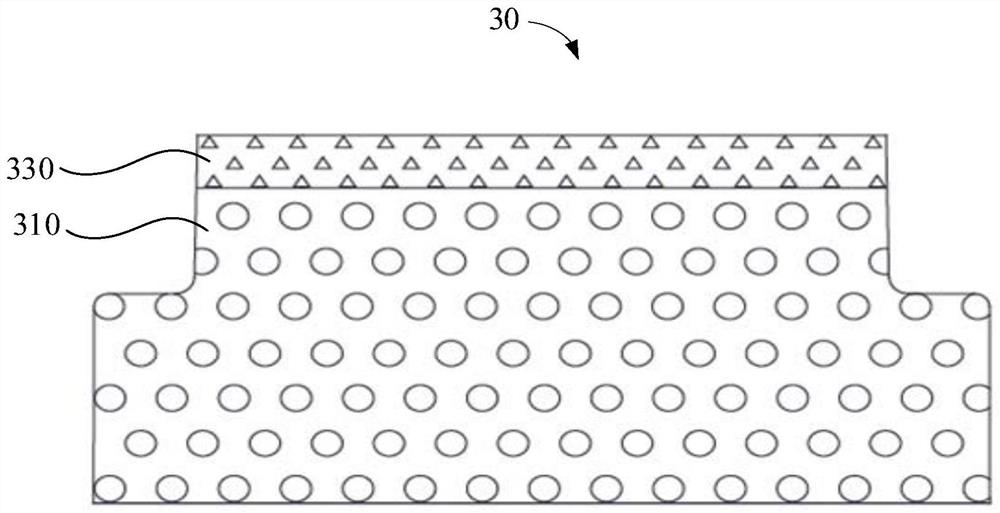

[0032] Step c. After distributing the dry granulated powder of each functional layer according to the preset gradient structure, press molding and sintering to make a gradient porous material with multiple functional layers.

[0033] Specifically, the raw materials of each functional layer include at least one of metal materials and non-metal materials. The solvent of the slurry is water or an organic solvent. The functional layer can be designed according to actual needs. For example, the functional layer ca...

Embodiment 1

[0073] (1) Dry granulated powder for alumina layer:

[0074] The raw materials of the alumina layer are firstly called: in parts by mass, 100 parts of alumina powder (median particle size is 50 microns), 2 parts of PVA, 10 parts of glass powder, 10 parts of carbon powder and 78 parts of water. Then grind and mix uniformly to form a stable water-based slurry, and then spray-dry at 250°C to form dry granulated powder for a 200-mesh alumina layer.

[0075] (2) Dry granulated powder for base layer:

[0076] First weigh the raw materials of the base layer: in parts by mass, 100 parts of diatomite powder (median particle size is 50 microns), 0.5 parts of PVA, 10 parts of high-temperature glass powder, 20 parts of carbon powder, and 69.5 parts of water . Then grind and mix evenly to form a stable water-based slurry, and then spray-dry at 250°C to form a dry granulated powder for the base layer of 200 meshes.

[0077] (3) The two kinds of powders prepared by step (1) and step (2) a...

Embodiment 2

[0079] (1) Dry granulation powder for glass ceramic layer:

[0080] The raw materials of the glass-ceramic layer: in parts by mass, 100 parts of high melting point glass powder (median particle size is 100 microns, melting point is above 600 ° C), 10 parts of Suzhou soil, 0.5 parts of PVA, 10 parts of carbon powder, and 70 parts of water. Then grind and mix uniformly to form a stable water-based slurry, and then spray-dry at 280°C to form dry granulated powder for a 100-mesh glass-ceramic layer.

[0081] (2) Dry granulated powder for base layer:

[0082] First weigh the raw materials of the base layer: in parts by mass, 100 parts of silicon carbide powder (median particle size is 100 microns), 2 parts of PVA, 15 parts of high-temperature glass powder, 10 parts of carbon powder, and 60 parts of water. Then grind and mix evenly to form a stable water-based slurry, and then spray-dry at 280°C to form a dry granulated powder for the base layer of 200 meshes.

[0083] (3) The tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com