Intermediate gas concentration adjusting piston pressure device of high-temperature and high-pressure kettle and gas distribution method

A high-temperature, high-pressure, piston pressure technology, used in methods of chemically changing substances using atmospheric pressure, gas and gas/vapor mixing, piston pumps, etc. Simulate the actual working conditions and other problems in the field to achieve the effect of improving reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

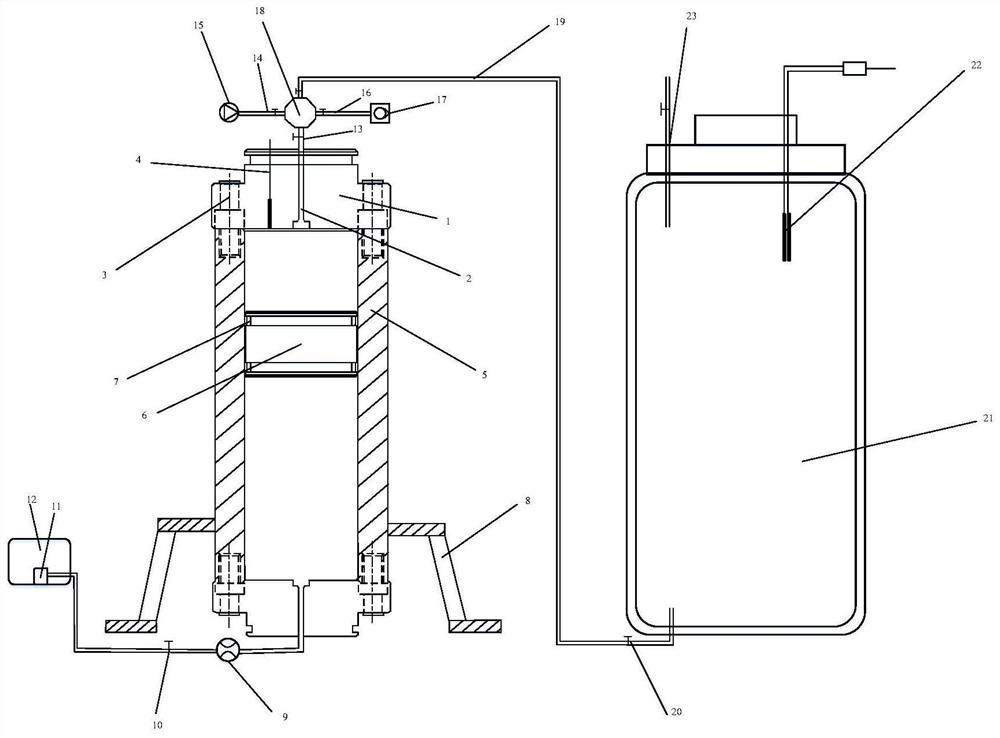

[0027] Such as figure 1 As shown, a high-temperature autoclave intermediate gas concentration adjustment piston pressure device, including a gas concentration adjustment piston pressure device and a high-temperature autoclave 21;

[0028] The gas concentration adjustment piston pressure device includes: a plug 1, a cylinder 5, a piston 6, an oil tank 12, a base 8 and an oil pipe;

[0029] A piston 6 is set inside the cylinder 5, and the upper opening of the cylinder 5 is sealed by a plug 1, and the plug 1 is fixed on the cylinder 5 by a screw 3;

[0030] A concentration probe 4 and a ventilation connection pipe 2 are installed on the plug 1, and the concentration probe 4 and the ventilation connection pipe 2 both pass through the plug 1 and pass into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com