Extraction process and application of ginseng polypeptide

An extraction process, ginseng technology, applied in the field of extraction process containing ginseng polypeptide, can solve the problems of poor separation effect of ultra-microfiltration membrane, and achieve the effect of improving biological permeability and good bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A process for extracting ginseng polypeptides, comprising the following steps:

[0055] S1 pretreatment: drying the flowers, leaves and roots of ginseng at 10.5°C for 0.5h to obtain raw material A with a moisture content of 7%;

[0056] S2 crushing: crush raw material A to 50 mesh to obtain powder B; drying: dry powder B at 10.5°C for 1 hour to obtain powder C with a moisture content of less than 5%;

[0057] S3 extraction: the powder C is passed through a silica gel column, the extraction temperature is 20°C, the pressure is 5MPa, the extraction time is 1h, the flow rate of ethanol is 500kg / h, and the entrainer ethyl acetate is also added during the extraction. The weight ratio of powder C is 0.3:100; liquid D and residue E are obtained after extraction, residue E is subjected to secondary extraction at a temperature of 20°C and a pressure of 5MPa, the extraction time is 1h, and the flow rate of carbon dioxide is 500kg / h. get the extract;

[0058] S4 Separation: Mix ...

Embodiment 2

[0063] A process for extracting ginseng polypeptides, comprising the following steps:

[0064] S1 pretreatment: drying the flowers, leaves and roots of ginseng at 10.5°C for 0.5h to obtain raw material A with a moisture content of 7%;

[0065] S2 crushing: crush raw material A to 50 mesh to obtain powder B; drying: dry powder B at 10.5°C for 1 hour to obtain powder C with a moisture content of less than 5%;

[0066] S3 extraction: the powder C is passed through a silica gel column, the extraction temperature is 20°C, the pressure is 5MPa, the extraction time is 1h, the flow rate of ethanol is 500kg / h, and the entrainer ethyl acetate is also added during the extraction. The weight ratio of powder C is 0.3:100; liquid D and residue E are obtained after extraction, residue E is subjected to secondary extraction at a temperature of 20°C and a pressure of 5MPa, the extraction time is 1h, and the flow rate of carbon dioxide is 500kg / h. get the extract;

[0067] S4 Separation: Mix ...

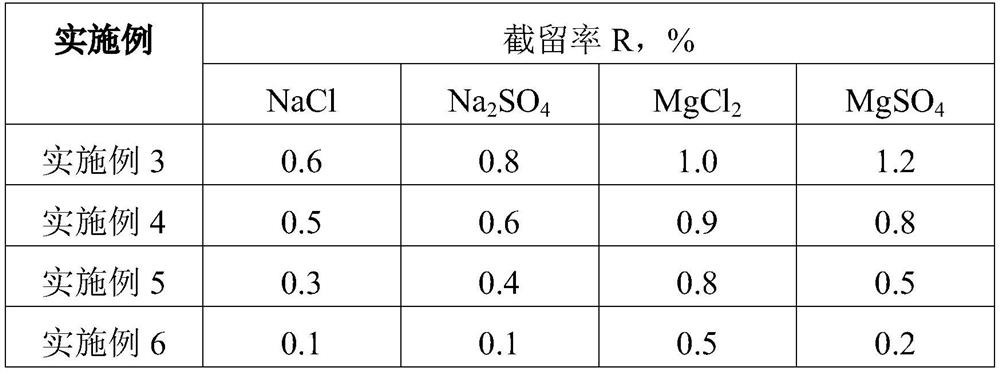

Embodiment 3

[0072] A process for extracting ginseng polypeptides, comprising the following steps:

[0073] S1 pretreatment: drying the flowers, leaves and roots of ginseng at 10.5°C for 0.5h to obtain raw material A with a moisture content of 7%;

[0074] S2 crushing: crush raw material A to 50 mesh to obtain powder B; drying: dry powder B at 10.5°C for 1 hour to obtain powder C with a moisture content of less than 5%;

[0075] S3 extraction: the powder C is passed through a silica gel column, the extraction temperature is 20°C, the pressure is 5MPa, the extraction time is 1h, the flow rate of ethanol is 500kg / h, and the entrainer ethyl acetate is also added during the extraction. The weight ratio of powder C is 0.3:100; liquid D and residue E are obtained after extraction, residue E is subjected to secondary extraction at a temperature of 20°C and a pressure of 5MPa, the extraction time is 1h, and the flow rate of carbon dioxide is 500kg / h. get the extract;

[0076] S4 Separation: Mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com