Bamboo leaf flavonoid tablet and preparation method thereof

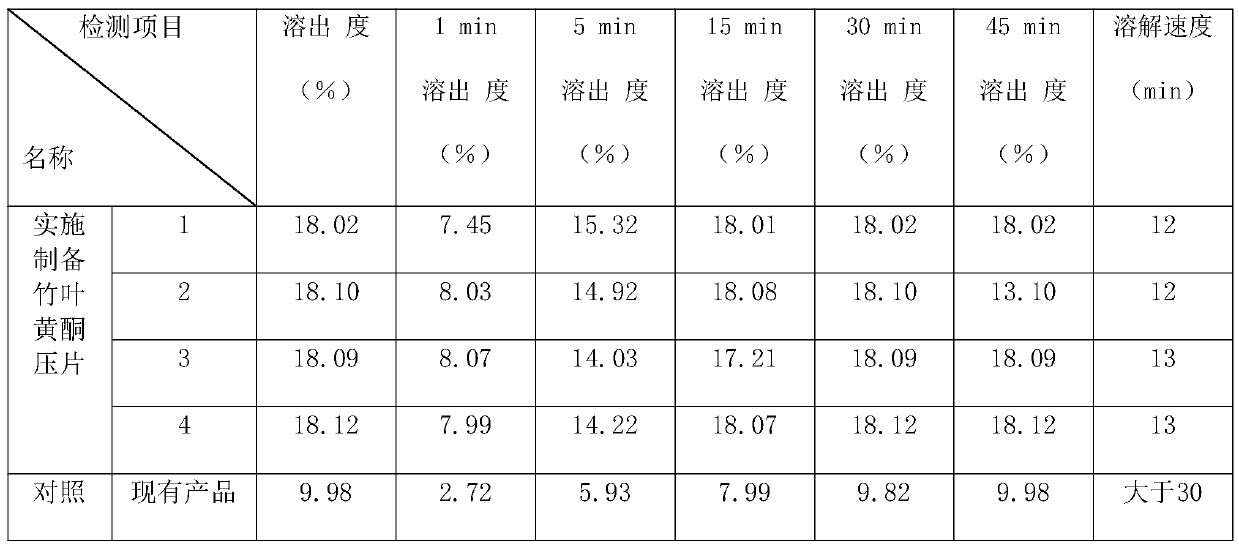

A technology of bamboo leaf flavonoids and tableting, applied in the field of bamboo leaf flavonoid tableting and preparation thereof, can solve the problems of slow dissolution rate of active ingredients, low bioavailability of effective active molecules, etc., achieves reduction of medication cost, prevention of cardiovascular and cerebrovascular diseases Disease, rapid dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: A kind of bamboo leaf flavone compressed tablet

[0021] 30 parts of bamboo leaf flavonoids, 5 parts of corn peptide (5 parts of corn oligopeptide powder), 20 parts of thickener (10 parts of maltodextrin, 10 parts of microcrystalline cellulose), 20 parts of sweetener (10 parts of xylooligosaccharide , xylitol 5 parts) 15 parts, soybean lecithin 15 parts, food preservatives (0.2 parts of citric acid, D-sodium erythorbate 0.3 parts) 0.5 parts, glidant auxiliary materials (magnesium stearate 1.0 parts, micronized silica gel 2.0 parts) 3 parts.

[0022] The corn peptide is corn oligopeptide powder;

[0023] The thickener is a mixture of maltodextrin and microcrystalline cellulose;

[0024] The sweetener is a mixture of xylooligosaccharides and xylitol.

[0025] The food preservative is a mixture of citric acid and sodium D-isoascorbate;

[0026] The glidant auxiliary material is a mixture of magnesium stearate and micropowder silica gel.

[0027] Describe...

Embodiment 2

[0030] Embodiment 2: A kind of bamboo leaf flavone compressed tablet

[0031] 10 parts of bamboo leaf flavonoids, 20 parts of corn peptide (20 parts of corn oligopeptide powder), 5 parts of thickener (2 parts of maltodextrin, 2 parts of microcrystalline cellulose, 1 part of corn starch), 5 parts of sweetener (maltose 2 parts of alcohol, 2 parts of steviol glycoside, 1 part of trehalose) 5 parts, 5 parts of soybean lecithin, 3 parts of food preservatives (2 parts of malic acid, 1 part of lactic acid), excipients of glidants (0.5 parts of magnesium stearate ) 0.5 parts.

[0032] The corn peptide is corn oligopeptide powder;

[0033] The thickener is a mixture of maltodextrin, microcrystalline cellulose and cornstarch;

[0034] The sweetener is a mixture of maltitol, steviol glycoside and trehalose;

[0035] The food preservative is a mixture of malic acid and lactic acid;

[0036] The glidant auxiliary material is magnesium stearate.

[0037] The food-grade coating agent is...

Embodiment 3

[0040] Embodiment 3: A kind of bamboo leaf flavone compressed tablet

[0041] Raw materials in the following mass ratios: 10 parts of bamboo leaf flavonoids, 12 parts of corn peptide (12 parts of corn oligopeptide powder), thickener (5 parts of maltodextrin, 5 parts of microcrystalline cellulose, 2 parts of sodium carboxymethyl cellulose 12 parts), sweetener (8 parts of xylooligosaccharide, 1 part of maltitol, 1 part of trehalose) 10 parts, 10 parts of soybean lecithin, food preservative (1.0 parts of citric acid, 0.5 parts of sodium D-isoascorbate ) 1.5 parts, glidant auxiliary materials (magnesium stearate 1.0 part, talcum powder 0.5 part) 1.5 parts.

[0042] The corn peptide is corn oligopeptide powder;

[0043] The thickener is a mixture of maltodextrin, microcrystalline cellulose and sodium carboxymethyl cellulose;

[0044] The sweetener is a mixture of xylooligosaccharides, maltitol and trehalose.

[0045] The food preservative is a mixture of citric acid and sodium D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com