Preparation method of preparing inorganic fullerene enhanced aluminum-based nano composite material

A nano-composite material and reinforced aluminum-based technology, applied in the direction of additive processing, etc., can solve the problems of difficulty in uniform dispersion and easy aggregation of inorganic fullerene nanoparticles, and achieve high practical value, good application prospects, and low preparation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

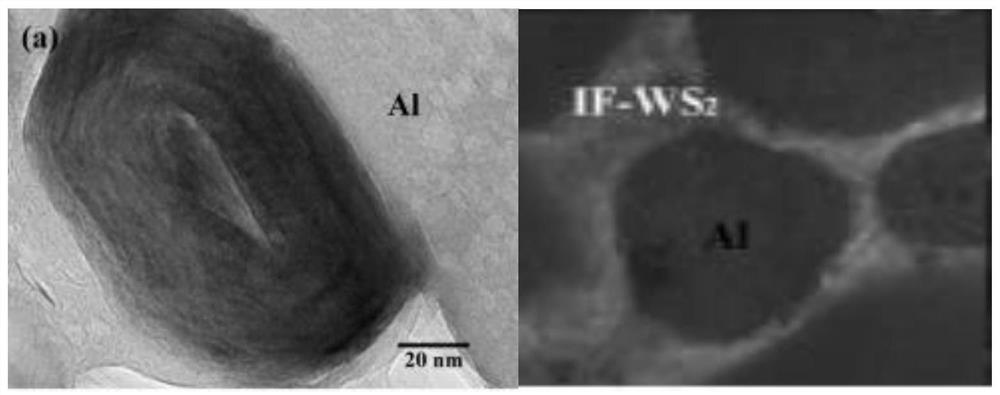

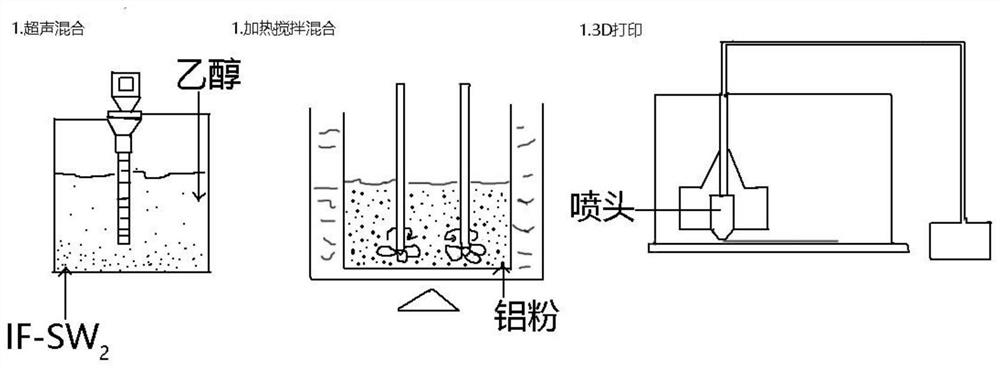

[0025] (1) The prepared inorganic fullerene nanoparticles (IF-WS2 size is about 40nm) are uniformly dispersed in the ethanol medium with the help of an ultrasonic probe, and mixed for about 60 minutes.

[0026] (2) Heat the above solution to 80°C, add aluminum powder particles and mix thoroughly, and stir vigorously until the ethanol is completely volatilized to obtain a mixed solid sample of 20wt% IF-WS2 and aluminum powder, and then place it in an oven at 120°C Let dry for 12 hours.

[0027] (3) Place the dried sample in the 3D printing machine, and the mixed solid sample is extruded by the nozzle of the FDM machine. The heating temperature of the nozzle is 560°C. After extrusion, the aluminum matrix reinforced with inorganic fullerene can be obtained by cooling. nanocomposites.

[0028] After vacuum-drying the obtained sample, observe its microscopic form with a scanning electron microscope and a transmission electron microscope, and its microscopic form is as attached fi...

Embodiment 2

[0030] (1) The prepared inorganic fullerene nanoparticles (IF-WS2 size is about 40nm) are uniformly dispersed in the ethanol medium with the help of an ultrasonic probe, and mixed for about 60 minutes.

[0031] (2) Heat the above solution to 80°C, add aluminum powder particles and mix thoroughly, and stir vigorously until the ethanol is completely volatilized to obtain a mixed solid sample of 30wt% IF-WS2 and aluminum powder, and then place it in an oven at 120°C Let dry for 12 hours.

[0032] (3) Place the dried sample in the 3D printing machine, and the mixed solid sample is extruded by the nozzle of the FDM machine. The heating temperature of the nozzle is 560°C. After extrusion, the aluminum matrix reinforced with inorganic fullerene can be obtained by cooling. nanocomposites.

Embodiment 3

[0034] (1) The prepared inorganic fullerene nanoparticles (IF-WS2 size is about 40nm) are uniformly dispersed in the ethanol medium with the help of an ultrasonic probe, and mixed for about 60 minutes.

[0035] (2) Heat the above solution to 80°C, add aluminum powder particles, mix well, and stir vigorously until the ethanol is completely volatilized, and prepare a mixed solid sample of 20wt% IF-WS2 and aluminum powder, and then place it in an oven at 120°C Let dry for 12 hours.

[0036] (3) Place the dried sample in the 3D printing machine, and the mixed solid sample is extruded by the nozzle of the FDM machine. The heating temperature of the nozzle is 650°C. After extrusion, the aluminum matrix reinforced with inorganic fullerene can be obtained by cooling. nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com