Anti-blocking type furnace pressure tapping device of closed submerged arc furnace

A submerged arc furnace and anti-blocking technology, which is applied to furnace monitoring devices, measuring devices, furnaces, etc., can solve problems such as blockage of pressure pipes, and achieve the effects of convenient manufacturing and installation, ensuring continuous measurement, and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] The specific implementation of this embodiment is as follows.

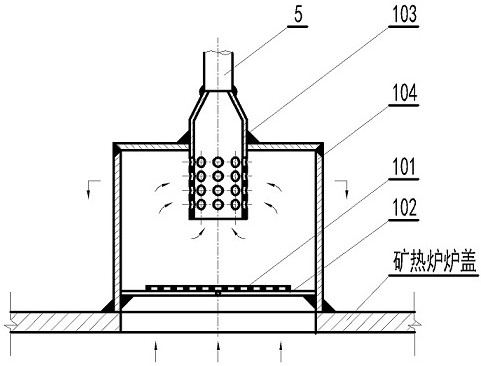

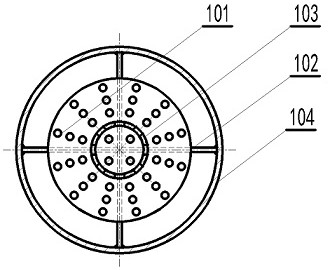

[0025] Such as figure 2 As shown, two anti-blocking pressure-taking boxes 1 are manufactured. Weld the electrostatic sedimentation orifice plate 101 on the bracket 102, then weld the bracket 102 on the mouth of the pressure equalization chamber cover 104, insert the pressure taking hole tube 103 into the inside of the pressure equalization chamber cover 104, and weld it to the top of the pressure equalization chamber cover 104 .

[0026] Select two positions on the furnace cover of the submerged arc furnace to open two round holes, and weld the anti-blocking pressure-taking box 1 at the opening positions.

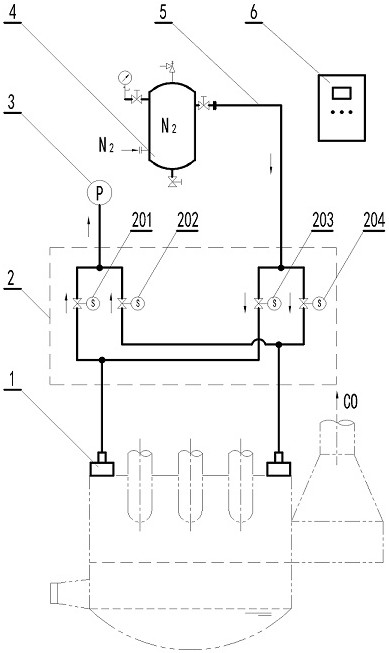

[0027] Press as figure 1 As shown in the connection relationship, use conduit 5 to connect anti-blocking pressure box 1, solenoid valve group 2, pressure transmitter 3, nitrogen tank 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com