Design method of mix proportion of warm mixed large volume recycled asphalt mixture

A technology of mix ratio design and recycled asphalt, which is applied in computer material science, instrumentation, informatics, etc., can solve the problems of poor performance of warm asphalt mixture, achieve stable technical support, improve stability, and improve ductility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The selected gradation type is AC-13, and the RAP content is 65%.

[0071] A dilapidated road surface in Ningxia was planed and crushed and sieved, and the aged asphalt was extracted by the Abson method, and the gradation and performance after RAP extraction, as well as the content and performance of the aged asphalt were tested, see Table 1-3.

[0072] Table 1 RAP detection performance

[0073] Material Moisture content, % Oil-stone ratio, % Sand equivalent, % RAP 1.52 5.1 57.3

[0074] Table 2 Bitumen properties

[0075] Material Penetration, 25℃ Softening point, °C 15℃ ductility, cm Viscosity at 60°C, Pa·s old asphalt 31 62 1.3 280.3 A-70 asphalt 73.5 56 110 189.2 waste mixed asphalt 70 58 108 230.8

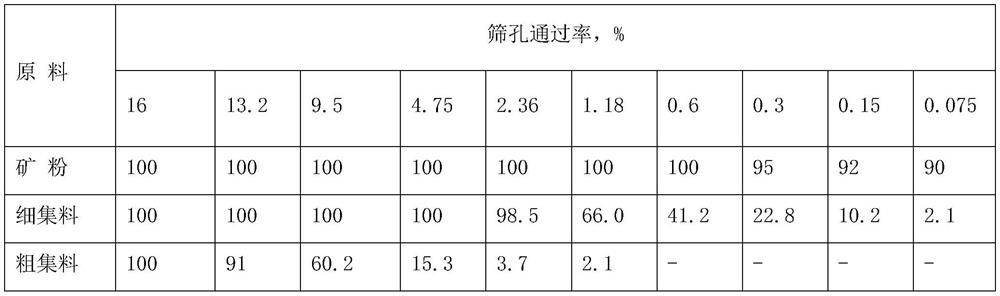

[0076] Table 3 RAP grading table

[0077] mesh size 16 13.2 9.5 4.75 2.36 1.18 0.6 0.3 0.15 0.075 pass,% 100 97.6 77.4 55.1 42.1 31.2 23.3 16.6 7.6 4.3 ...

Embodiment 2

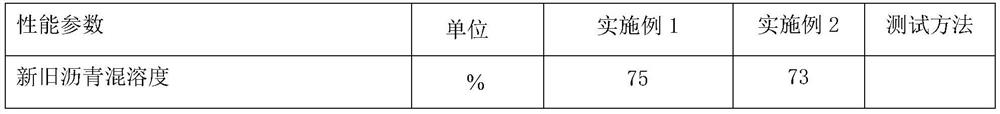

[0089] The selected gradation type is AC-13, and the RAP content is 75%. It is preliminarily determined that the admixture ratio of regenerant to old asphalt is 10%. The new asphalt is SBS modified asphalt I-C, and its properties are shown in Table 5. According to formula (2) and formula (3) and actual engineering experience, the amount of new asphalt is selected as 5%, and the amount of old asphalt is calculated to be about 3.8%. With the oil-stone ratio of 4.4 as the median value and 0.4% as the interval, according to the predetermined design of coarse aggregate, fine aggregate and mineral powder, the heating temperature of RAP old material is 120°C, the regenerant is added and the stirring temperature is 120°C, and the stirring time is 60S. Coarse aggregate, fine aggregate and mineral powder are added at a temperature of 130°C, and the mixing time is 50S; new asphalt is added at a temperature of 130°C, and the mixing time is 60S to prepare asphalt mixture, and the compacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com