Homotype heterostructure IMPATT diode and manufacturing method thereof

A heterostructure, diode technology, applied in diodes, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of high ambient temperature, affecting IMPATT output efficiency, large reverse leakage, etc., and achieve the effect of high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

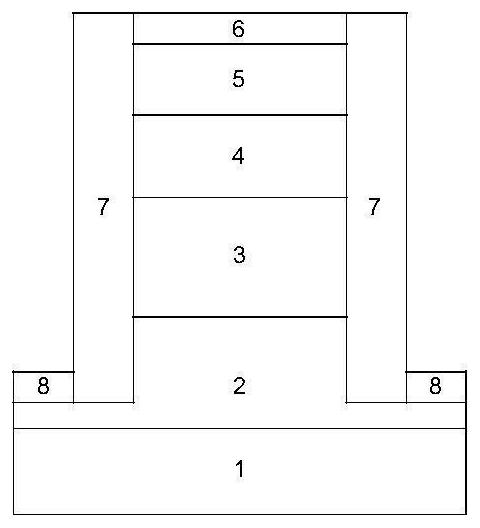

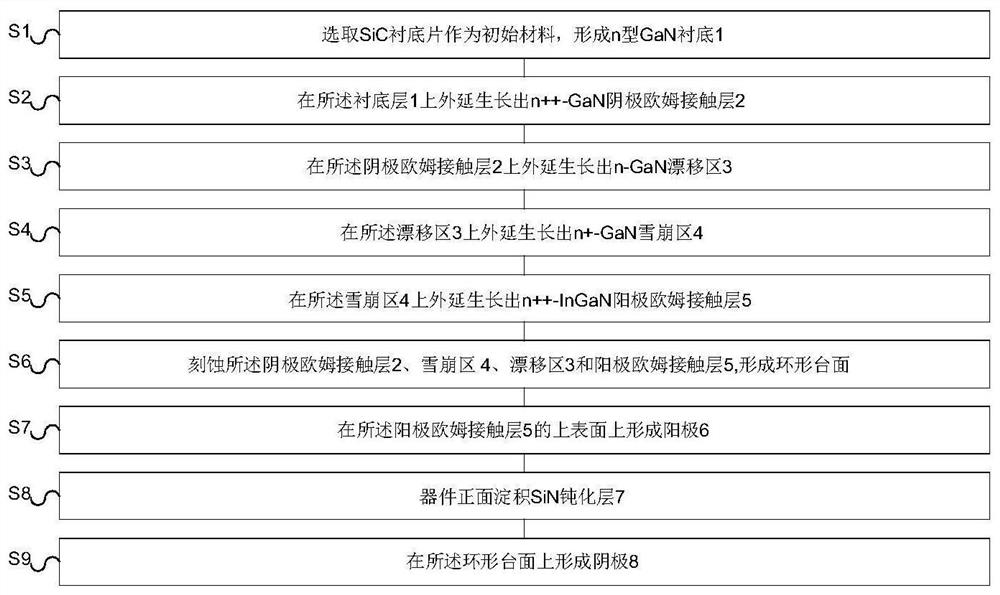

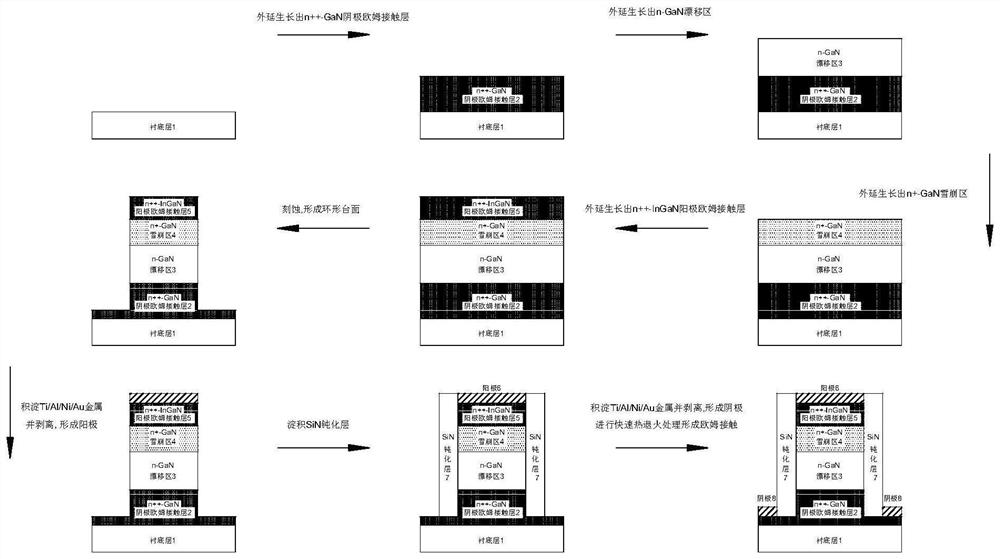

[0036] Such as figure 1 As shown, the same-type heterostructure IMPATT diode of the present invention includes an n-type GaN substrate 1, an n++-GaN cathode ohmic contact layer 2, an n-GaN drift region 3, and an n+-GaN avalanche region 4 arranged sequentially from bottom to top , n++-InGaN anode ohmic contact layer 5 and anode 6.

[0037] The passivation layer 7 is located outside the anode 6 , and the cathode 8 is located on the upper layer of the annular mesa formed by the n++-GaN cathode ohmic contact layer 2 and outside the passivation layer 7 .

[0038] In particular, the n-type GaN substrate 1, as the physical support layer of the device structure layer, not only perfectly matches the upper GaN multilayer structure, thereby significantly improving the crystal quality, but also plays a role in heat dissipation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com