Water-gas separation device for concentrated feed processing

A water-gas separation and concentrated feed technology, applied in the separation method, dispersed particle separation, gas treatment, etc., can solve the problems of poor exhaust gas purification effect, inconvenient fixing, inconvenient washing at the bottom of the recovery box, etc., to increase the degree of cleanliness , the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

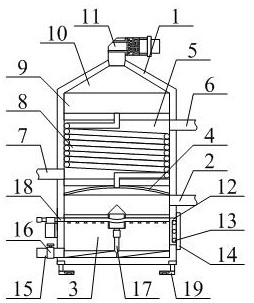

[0040] as attached figure 1 And attached Figure 4 shown

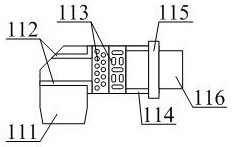

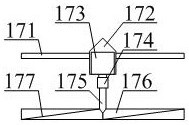

[0041]The invention provides a water-gas separation device for concentrated feed processing, comprising a casing 1, an introduction pipe 2, a recovery box 3, a guide cover 4, a cooling box 5, a water inlet pipe 6, a water outlet pipe 7, a spiral pipe 8, a fan 9, and a conical cover 10 , then remove the gas derivation purification frame structure 11, transparent cover 12, ultraviolet germicidal lamp 13, connecting cover 14, discharge pipe 15, discharge valve 16, slag cleaning and scraping frame structure 17, debris washing device 18 and rotatable Fixed support structure 19, the introduction pipe 2 is arranged on the upper right side of the recovery box 3, and runs through the right side of the shell 1; the recovery box 3 is embedded in the inner lower part of the shell 1; the guide cover 4 is screw-mounted On the top of the recovery box 3; the cooling box 5 is embedded in the middle of the shell 1; the water inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com