Gasoline engine particulate filter regeneration control method

A particle trap, regeneration control technology, applied in the direction of engine control, electric engine control automatic control, electrical control, etc., can solve the problems of exhaust system temperature out of control, increased after-treatment system damage, etc., to reduce the total time and alleviate the Combustion instability, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

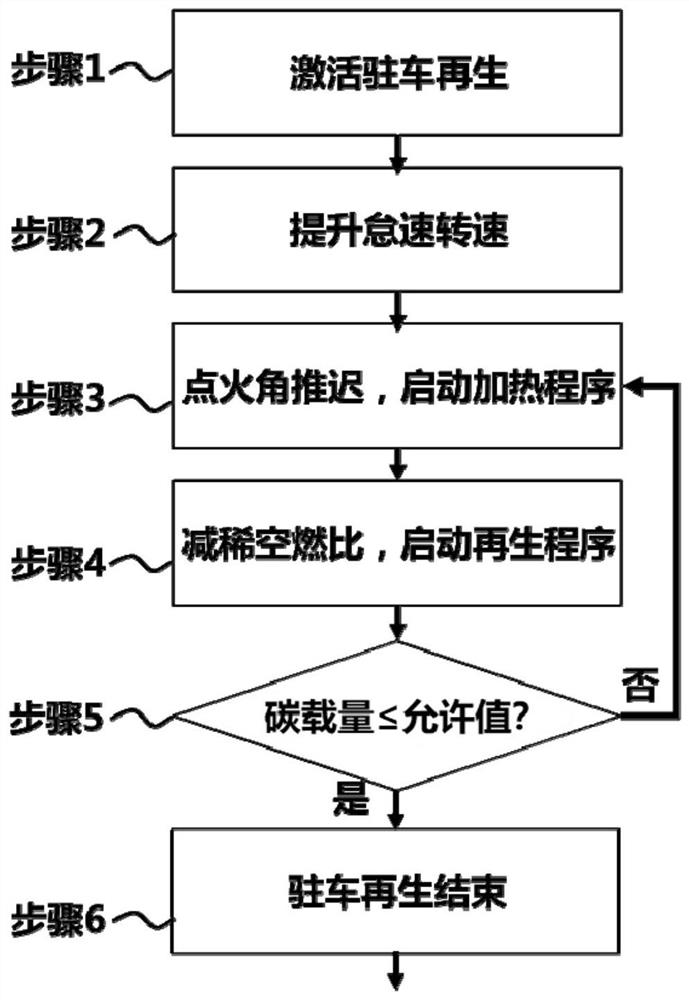

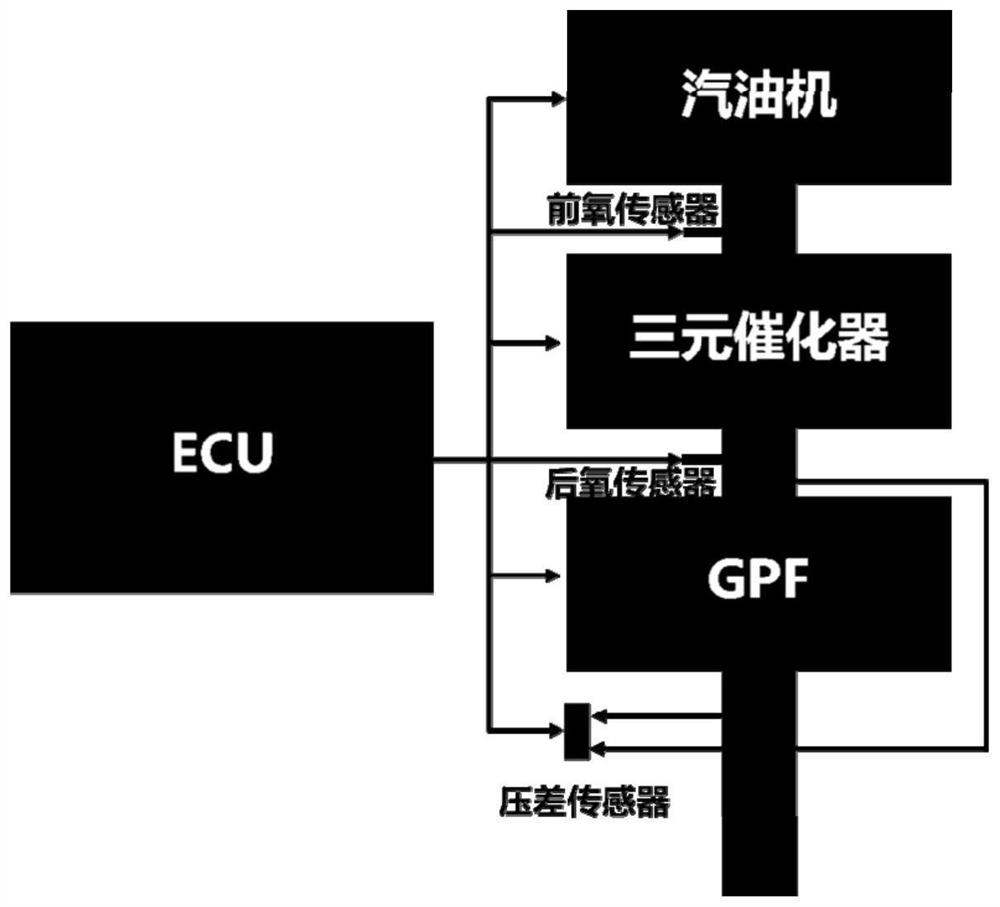

[0066] This embodiment provides a method for controlling the regeneration of a gasoline engine particulate filter, and the method includes the following steps:

[0067] (1) Detect the access signal of the parking regeneration program including water temperature and / or oil temperature, and enter the parking regeneration program;

[0068] (2) Increase the idle speed to R1=2500rpm;

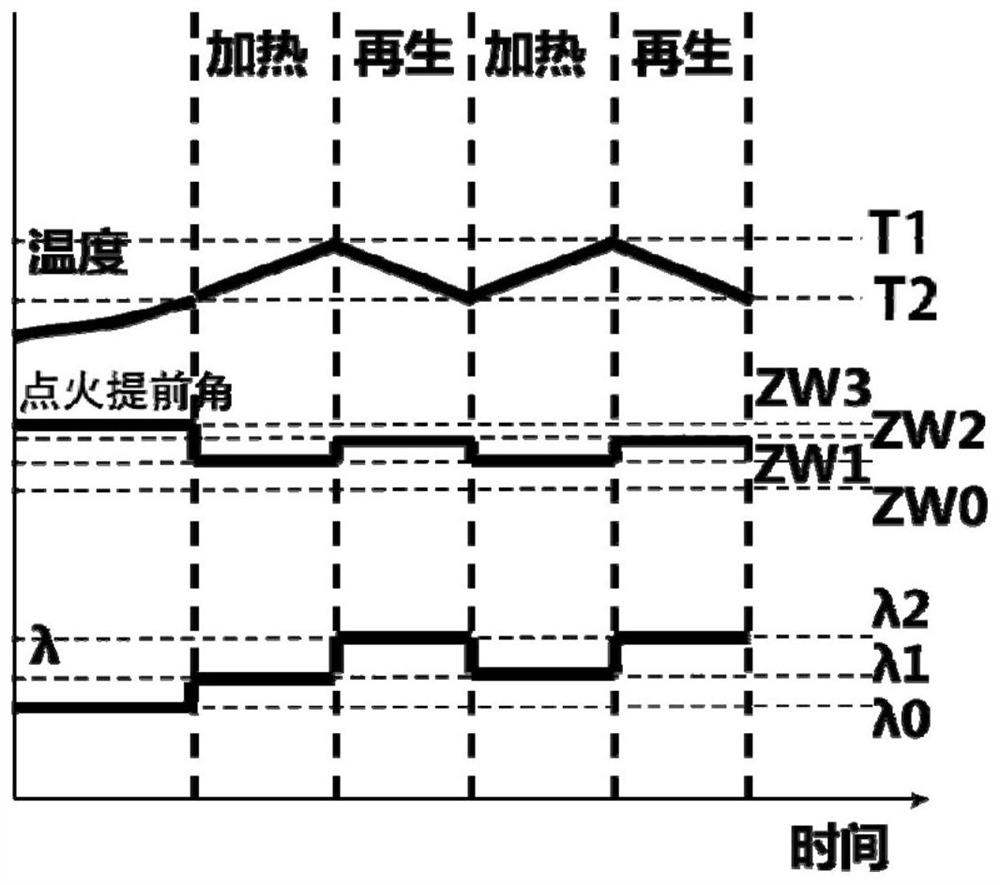

[0069] (3) Significantly reduce the ignition advance angle to ZW1=-15°C CA BTDC, reduce the air-fuel ratio to λ1=1.03, carry out exhaust heating, and stop heating when the temperature of the gasoline engine particle filter reaches the temperature threshold T1=700°C;

[0070] (4) Reduce the air-fuel ratio to λ2=1.15, reduce the ignition advance angle ZW2 to -5°C CA BTDC, and perform the regeneration of the gasoline engine particle filter, and stop the regeneration when the temperature of the gasoline engine particle filter reaches the temperature threshold T2=550°C ;

[0071] (5) Alternately perform...

Embodiment 2

[0073] This embodiment provides a method for controlling the regeneration of a gasoline engine particulate filter, and the method includes the following steps:

[0074] (1) Detect the access signal of the parking regeneration program including water temperature and / or oil temperature, and enter the parking regeneration program;

[0075] (2) Increase the idle speed to R1=2500rpm;

[0076] (3) Significantly reduce the ignition advance angle to ZW1=-15°C CA BTDC, control the air-fuel ratio at the stoichiometric air-fuel ratio to λ1=λ0=1, carry out exhaust heating, until the temperature of the gasoline engine particulate filter is the temperature threshold T1= Stop heating at 700°C;

[0077] (4) Reduce the air-fuel ratio to λ2=1.2, keep the ignition advance angle ZW2 unchanged at 23°C CA BTDC, perform regeneration of the gasoline engine particle filter, and stop when the temperature of the gasoline engine particle filter reaches the temperature threshold T2=550°C regeneration; ...

Embodiment 3

[0080] This embodiment provides a method for controlling the regeneration of a gasoline engine particulate filter, and the method includes the following steps:

[0081] (1) Detect the access signal of the parking regeneration program including water temperature and / or oil temperature, and enter the parking regeneration program;

[0082] (2) Increase the idle speed to R1=2000rpm;

[0083] (3) Significantly reduce the ignition advance angle to ZW1=-20°C CA BTDC, enrich the air-fuel ratio to λ1=0.9, carry out exhaust heating, and stop heating when the temperature of the gasoline engine particulate trap reaches the temperature threshold T1=700°C;

[0084] (4) Reduce the air-fuel ratio to λ2 = 1.15, keep the ignition advance angle ZW2 unchanged at 23°C CA BTDC, perform regeneration of the gasoline engine particulate filter, and stop when the temperature of the gasoline engine particulate filter reaches the temperature threshold T2 = 550°C regeneration;

[0085] (5) Alternately ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com