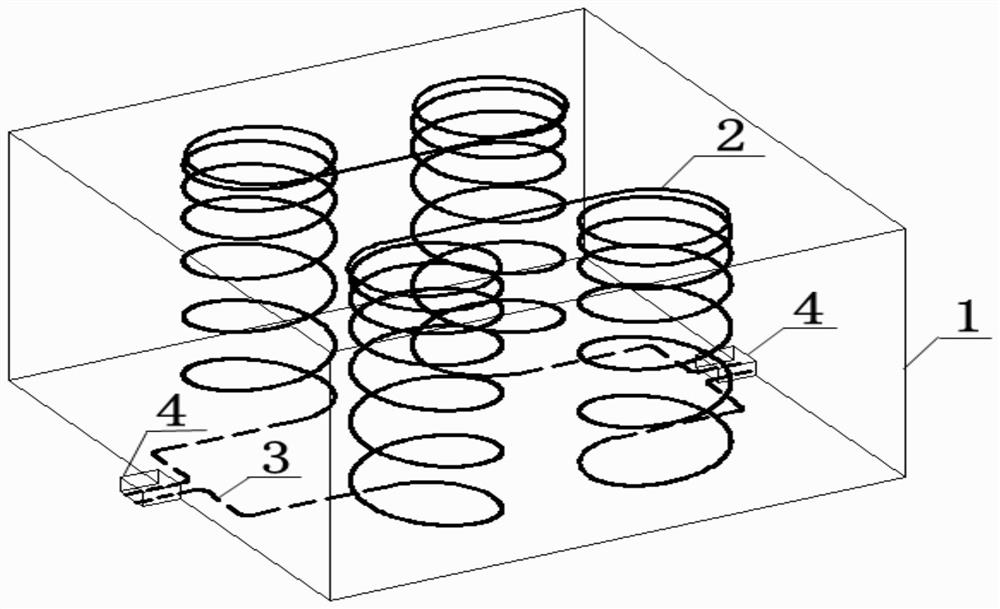

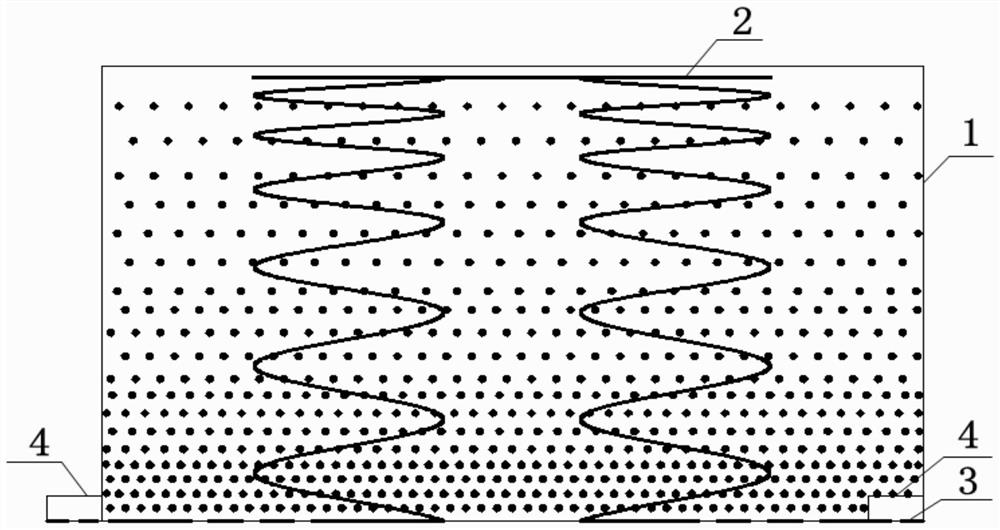

Composite phase change heat storage system with built-in electric heating and preparation method of composite phase change body

A technology of composite phase change and heat storage system, which is applied in the field of composite phase change heat storage system with built-in electric heating and the preparation of composite phase change body, which can solve the problems of large heat transfer resistance, low heat transfer efficiency, and short service life , to improve the heat transfer efficiency, facilitate the outward transfer of heat, and solve the effect of low heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0063] Embodiment 2: This embodiment is different from Embodiment 1 in that the housing 1 is made of high thermal conductivity insulating material, and the wall thickness of the housing 1 is no more than 2mm.

specific Embodiment approach 3

[0064] Embodiment 3: This embodiment differs from Embodiment 2 in that the high thermal conductivity insulating material refers to epoxy resin, rubber, and ceramics filled with metal oxides, metal nitrides, or metal carbides.

specific Embodiment approach 4

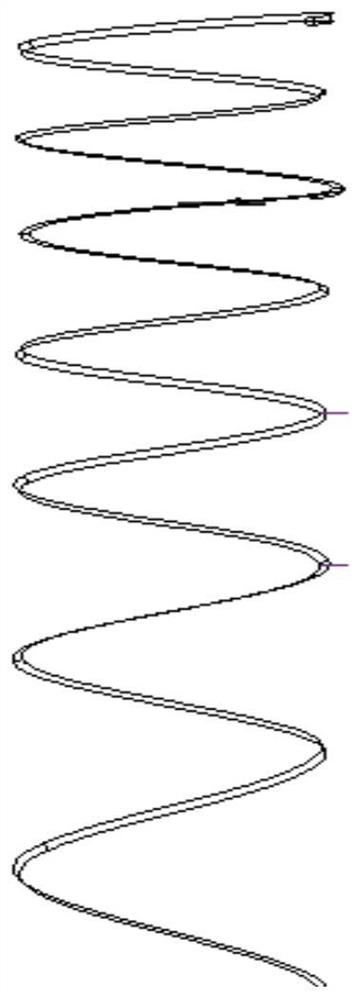

[0065] Embodiment 4: This embodiment is different from Embodiment 1 in that, in the cavity of the housing 1 , the spiral heating element 2 has a structure of dense top and sparse bottom.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com