A kind of installation structure applied to miniled and manufacturing method thereof

A technology of installation structure and production method, which is applied in the direction of assembling printed circuits with electrical components, identification devices, circuit heating devices, etc., can solve the problems of falling, unfavorable miniLED stability on the FPC substrate, etc., to prevent cracking, convenient and accurate. The effect of stable welding and accelerated heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

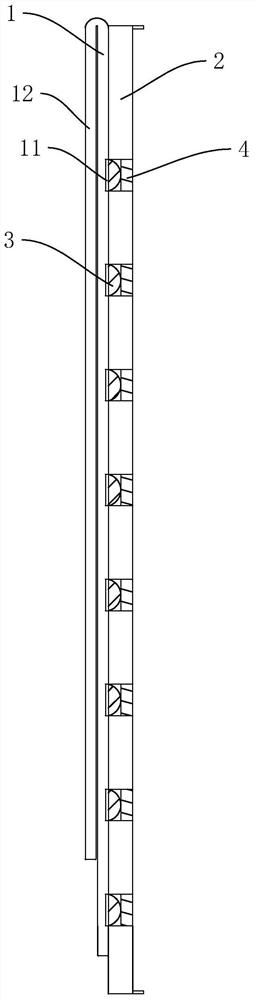

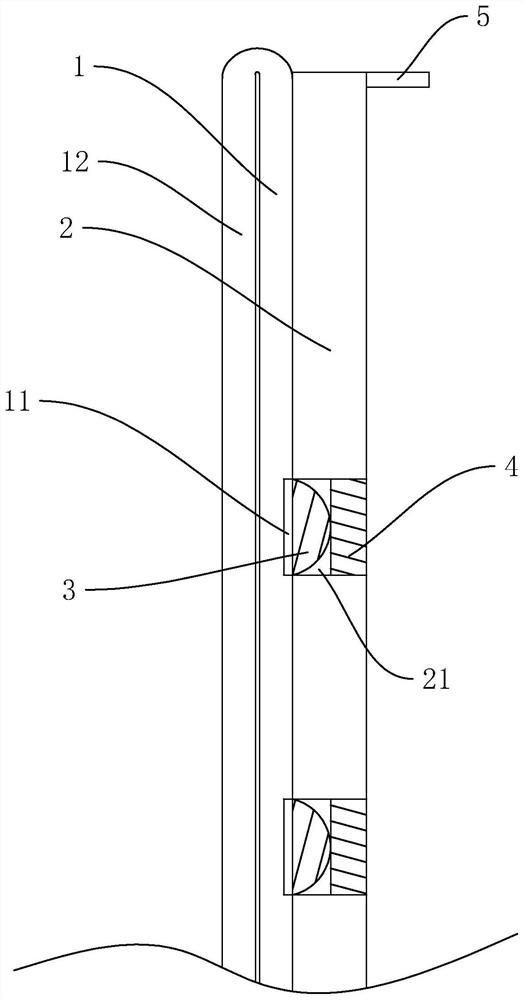

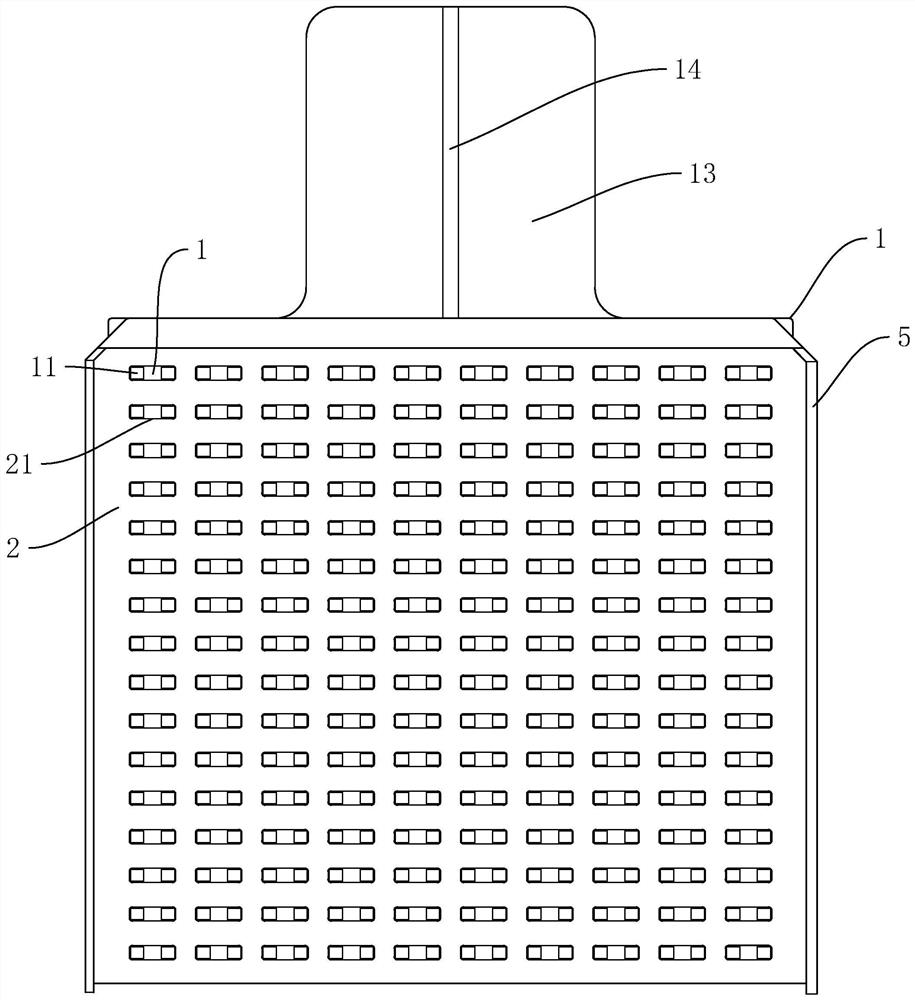

[0049] like figure 1 As shown, an installation structure applied to miniLED is used for the stable installation of miniLED4 to ensure that miniLED4 will not fall easily when subjected to external force. It includes FPC substrate 1, mesh board 2 and miniLED4. It is adapted and pasted on the FPC substrate 1 by adhesive tape. The miniLED4 is welded on the FPC substrate 1 through the solder paste 3 and the mesh 2. The overall thickness of the miniLED4 is the same as the thickness of the mesh 2. When the FPC substrate 1 is energized, the miniLED4 Shine bright. In addition, when the screen plate 2, FPC substrate 1 and miniLED4 are assembled together, it can be called an integrated light source for the backlight. When it is assembled with other backlight film materials, it will form a miniLED4 backlight module assembly.

[0050] like figure 2 As shown, the FPC s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com