Powder feeding system of nano powder preparation process

A nano-powder and powder-feeding technology, which is applied in the direction of nano-technology, can solve the problems of outside air entering, cutting off materials, and affecting the quality of nano-powders in the operation of the plasma furnace, so as to prevent unstable feeding and stabilize the plasma flame flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

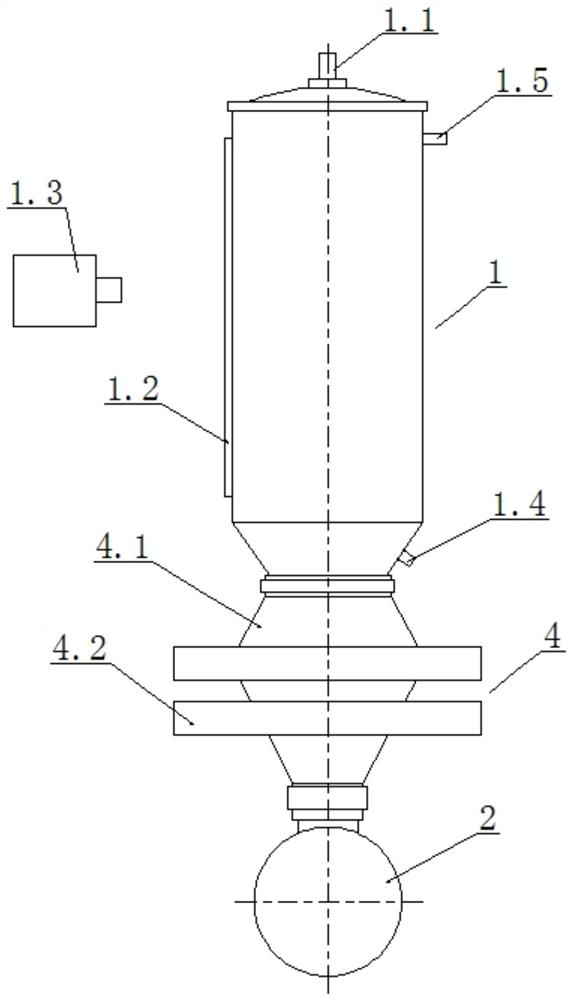

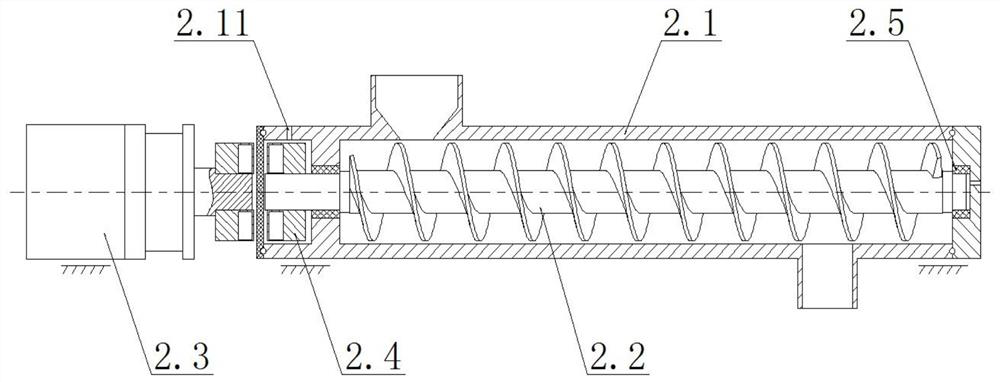

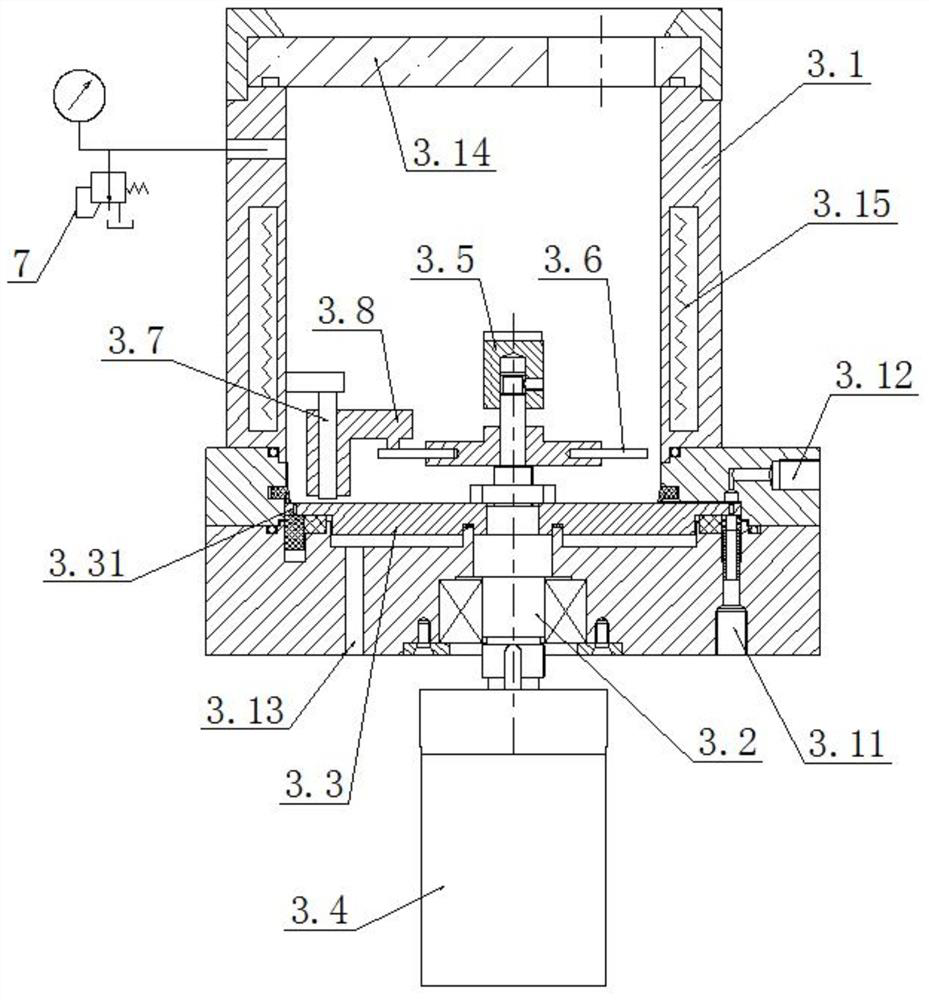

[0043] A powder feeding system for nano powder preparation process, such as Image 6 As shown, it includes a silo 1, a screw feeder 2, a powder feeder 3, a flexible pinch valve 4, an electronic scale 5, and a control device. The discharge port of the silo 1 is connected to the feed port of the screw feeder 2 through the flexible pinch valve 4 , and the discharge port of the screw feeder 2 is connected to the feed end of the powder feeder 3 through the flexible bellows 6 . The powder raw material in the silo 1 enters the powder feeder 3 quantitatively through the screw feeder 2 to ensure that the powder raw material in the powder feeder 3 is not fed continuously, so that the powder feeder 3 outputs a constant amount of powder raw material to the downstream equipment. The following is a detailed description:

[0044] Such as figure 1As shown, the silo 1 is arranged vertically, and the silo 1 is connected with a vacuuming device and a working gas refilling device. An air extra...

Embodiment 2

[0065] As described in Example 1, the powder feeding system of a nano-powder preparation process is different from Example 1 in that:

[0066] Such as Figure 7 , 8 As shown, a second shaft sleeve 3.9 made of nylon or tetrafluoroethylene is provided between the shaft hole and the shaft 3.2, and a vent hole is provided on the second shaft sleeve 3.9, and the vent hole communicates with the second high-pressure air passage 3.13. In the second high-pressure air channel 3.13, a high-pressure working gas is introduced, and the high-pressure working gas enters the shaft hole and the sealing ring through the vent hole to prevent the powder raw material from entering it.

[0067] In order to enhance the sealing performance and further improve the technical solution, the rotating shaft 3.2 is non-contact connected with the servo motor 3.4 through the second magnetic coupling transmission wheel. The second magnetic force coupling transmission wheel includes a second driving wheel and ...

Embodiment 3

[0069] As described in Example 1, the powder feeding system of a nano-powder preparation process is different from Example 1 in that:

[0070] Such as Figure 9 As shown, on the inner cavity wall of the powder feeding barrel 3.1, an L-shaped spring plate 8 is connected through a fixing pin, and a through hole is provided on the spring plate 8, and the through hole is sheathed on the rotating shaft 3.2. A wedge-shaped block 9 is connected to the spring plate 8 , and the wedge-shaped block 9 is provided with a wedge-shaped surface. A vibration block 10 is connected to the free end of the spring plate 8 . When the rotating shaft 3.2 rotated, the stirring rod 3.6 was in sliding contact with the wedge-shaped surface on the wedge-shaped block 9, so that the free end of the spring plate 8 was upwardly tilted. As the stirring rod 3.6 continues to rotate, the wedge-shaped surface on the wedge-shaped block 9 is out of contact with the stirring rod 3.6. Under the action of elasticity, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com