Tilting component of tilting rotor unmanned aerial vehicle, tiltable rotor unmanned aerial vehicle and using method

A technology for tilting rotors and drones, applied in the field of drones, can solve problems such as poor tilting efficiency, slow tilting speed, and difficult processing, and achieve the effects of reducing accident rates, improving reliability, and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

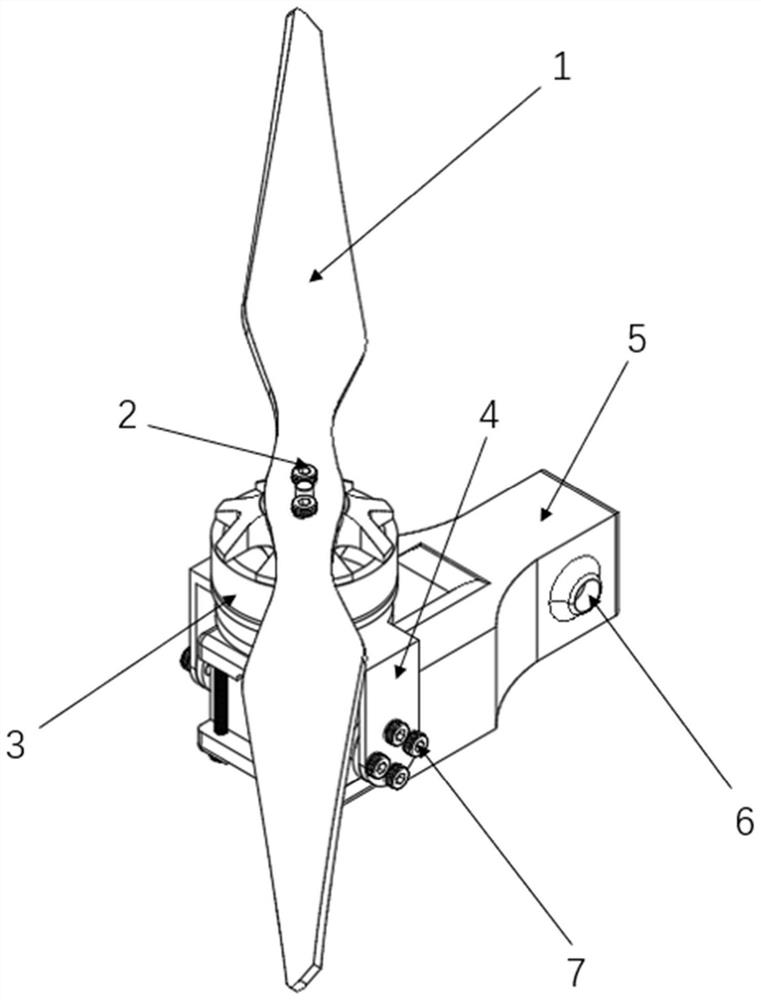

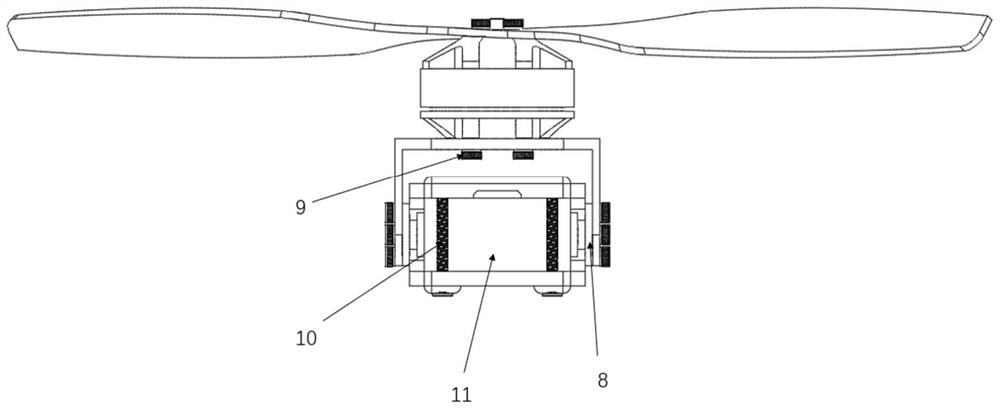

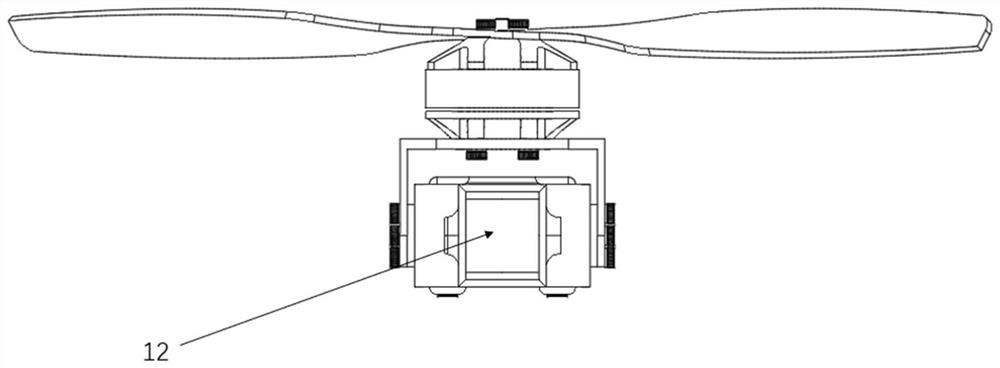

[0042] refer to Figure 1 to Figure 5 As shown, in this embodiment, the tilting components of the tiltrotor UAV include: propeller 1, propeller fixing screw 2, DC brushless motor 3, motor base 4, tilting base 5, and tilting base fixing screw hole 6 , Motor base fixing screw 7, steering gear plate 8, motor fixing screw 9, steering gear fixing screw 10, steering gear 11 and square hollow aluminum tube installation port 12.

[0043] Wherein, the propeller 1 is connected with the DC brushless motor 3, the DC brushless motor 3 is connected with the motor base 4, the motor base 4 is connected with two steering gear discs 8, and the steering gear disc 8 is connected with the steering gear 11 and then the steering gear can be driven Achieving tilting of the propeller.

[0044] Such as Figure 4 and Figure 5 shown, and refer to the Figure 1 to Figure 3 It can be seen that in this embodiment, a method for using a tilt-rotor UAV is also proposed, which includes the following steps:...

Embodiment 2

[0049] In this embodiment, the tiltable-rotor UAV includes a fuselage and wings, wherein, along the axial direction, one end of the fuselage is the nose, the other end is the tail, and the tail is provided with an empennage; The wings are arranged on both sides of the fuselage in pairs, and a tilting part is arranged away from the end of the fuselage along the extending direction of the wings.

[0050] The structure of the tilting part can refer to Figure 1 to Figure 5 The tiltrotor UAV shown tilts the parts.

[0051] Among them, when the tilting part is in the first station (the structure at this time refers to figure 1 As shown), the motor unit drives the motor to work so that the screw rotates on the first rotation plane, and the first rotation plane is parallel to the plane where the wing is located;

[0052] When the tilting part is in the second position (the structural reference at this time Figure 4 As shown), the motor unit drives the motor to work so that the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com