Dechroming carbon-maintaining method for smelting Cr-containing molten iron through top-bottom combined blowing converter and application

A converter smelting and top-bottom re-blowing technology is applied in the field of dechromizing and carbon-preserving Cr-containing molten iron in top-bottom combi-blowing converter smelting, and in the field of dechromizing and carbon-preserving in converter smelting Cr-containing molten iron, which can solve huge cost losses and increase converter steel production. Material consumption, enhanced oxidation of molten steel in converter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

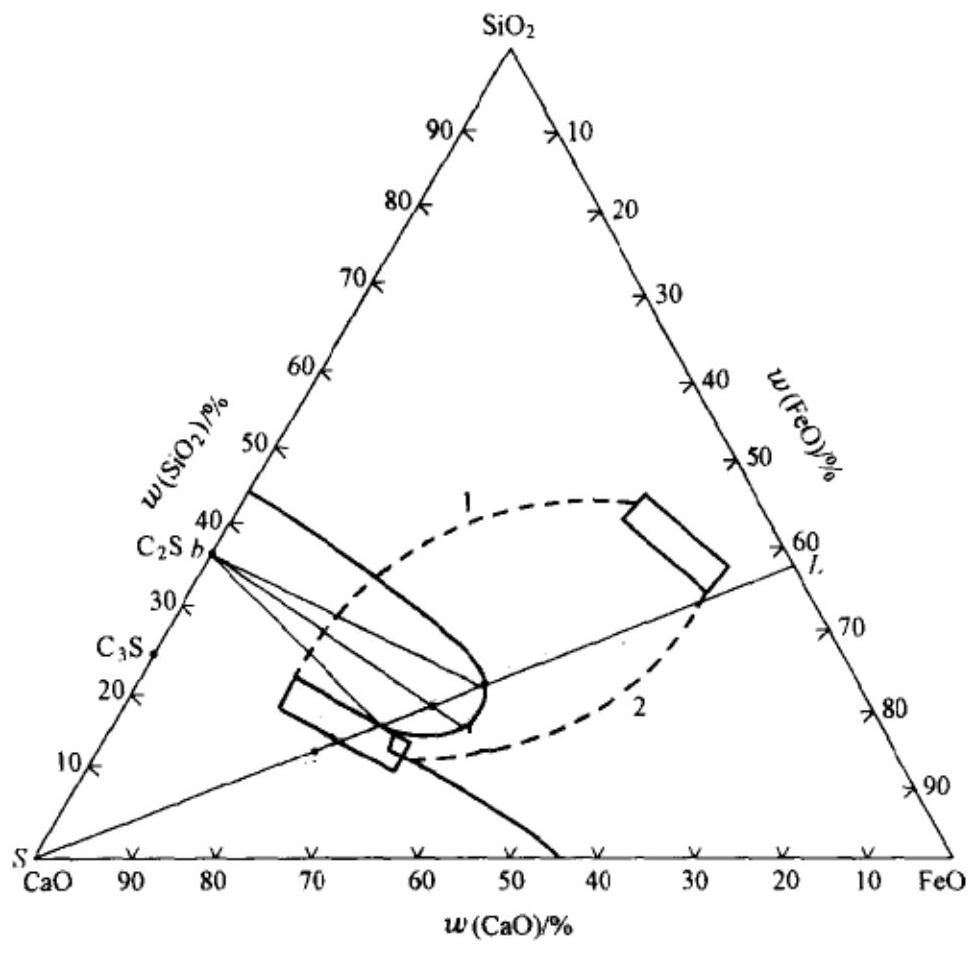

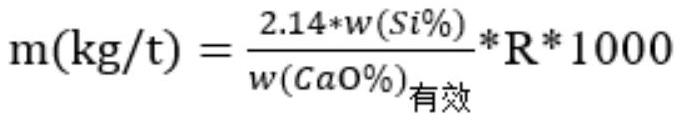

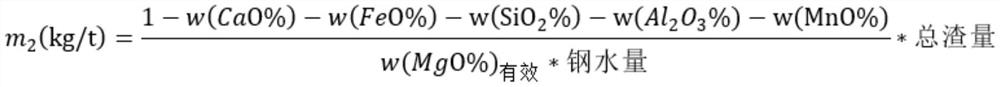

Method used

Image

Examples

Embodiment 1

[0061] Add scrap steel with a weight of 28.1t and a Cr element content of ≤0.08% into a 120t top-bottom combined blowing converter. The blending temperature is 1376°C. : 0.18%, molten iron with a weight of 106t (the ratio of molten iron is 79.06%) is smelted, wherein the bottom blowing gas is nitrogen, and the bottom blowing mode is set as: from the start of blowing to the start of blowing for 5 minutes, and the flow rate of the inert gas is controlled at 0.12 N m 3 min -1 ·t -1 , 6-12 minutes after the opening of the blowing, the flow rate of the bottom blowing inert gas is controlled at 0.05Nm 3 min -1 ·t -1 ; From the 13th minute after the opening of the blowing to the end of the inert gas blowing, the flow rate of the bottom blowing inert gas is controlled at 0.04Nm 3 min -1 ·t -1 . After the blowing is started, the gun position is controlled at 1.3-2.0m, 1278kg of magnesium balls and 963kg of lightly burned dolomite are added within the first 3 minutes, then a tot...

Embodiment 2

[0063] Add scrap steel with a weight of 27t and a Cr element content of ≤0.08% into a 120t top-bottom combined blowing converter. The blending temperature is 1375°C, and the composition contains C: 4.37%, Si: 0.62%, P: 0.110%, Cr: 0.22% molten iron with a weight of 104.6t (the molten iron ratio is 79.48%) for smelting, wherein the bottom blowing gas is nitrogen, and the bottom blowing mode is set as: from the start of blowing to the start of blowing for 5 minutes, and the flow rate of the inert gas is controlled at 0.12 N m 3 min -1 ·t -1 , 6-12 minutes after the opening of the blowing, the flow rate of the bottom blowing inert gas is controlled at 0.05Nm 3 min -1 ·t -1 ; From the 13th minute after the opening of the blowing to the end of the inert gas blowing, the flow rate of the bottom blowing inert gas is controlled at 0.04Nm 3 min -1 ·t -1 . After the blowing is started, the gun position is controlled at 1.3-2.0m, 1498kg of magnesium balls and 2067kg of lightly bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com