High-carbon bearing steel and preparation method thereof

A high-carbon bearing and bearing steel technology, which is applied to bearings, shafts, bearings, bearing components, etc., can solve the problems of reducing bearing precision, increasing bearing manufacturing cost, and increasing the difficulty of bearing manufacturing, so as to achieve fatigue life improvement and fine carbonization material, improving mechanical properties and contact fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

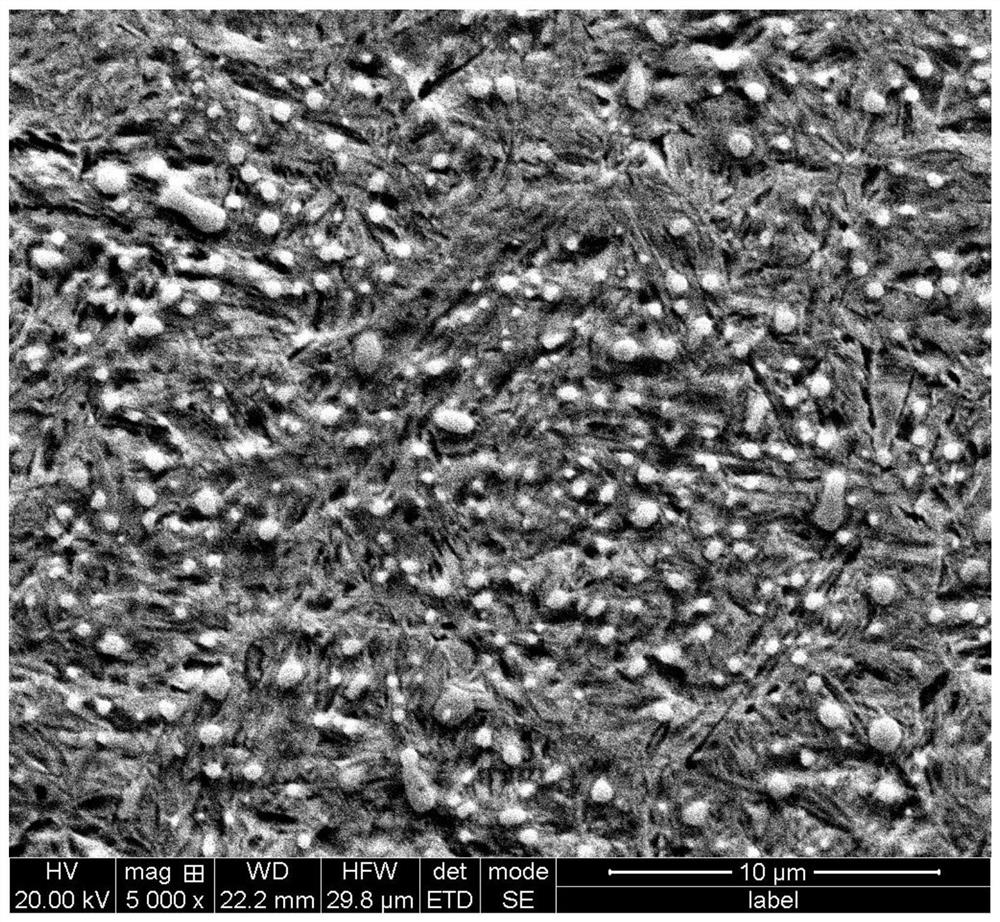

Image

Examples

preparation example Construction

[0034] The present invention provides a method for preparing high-carbon bearing steel described in the above scheme, comprising the following steps:

[0035] Smelting the raw materials for the preparation of high-carbon bearing steel to obtain a steel ingot; the chemical composition of the steel ingot corresponds to the chemical composition of the high-carbon bearing steel described in the above scheme;

[0036] After the steel ingot is subjected to homogenization treatment, it is processed into a bar;

[0037] Spheroidizing annealing, quenching and tempering are sequentially performed on the bar to obtain high carbon bearing steel.

[0038]The invention smelts the preparation raw materials of the high-carbon bearing steel to obtain steel ingots. In the present invention, the smelting method is preferably electroslag smelting, double vacuum smelting, out-of-furnace refining or vacuum induction furnace smelting. The present invention has no special requirements on the smelti...

Embodiment 1

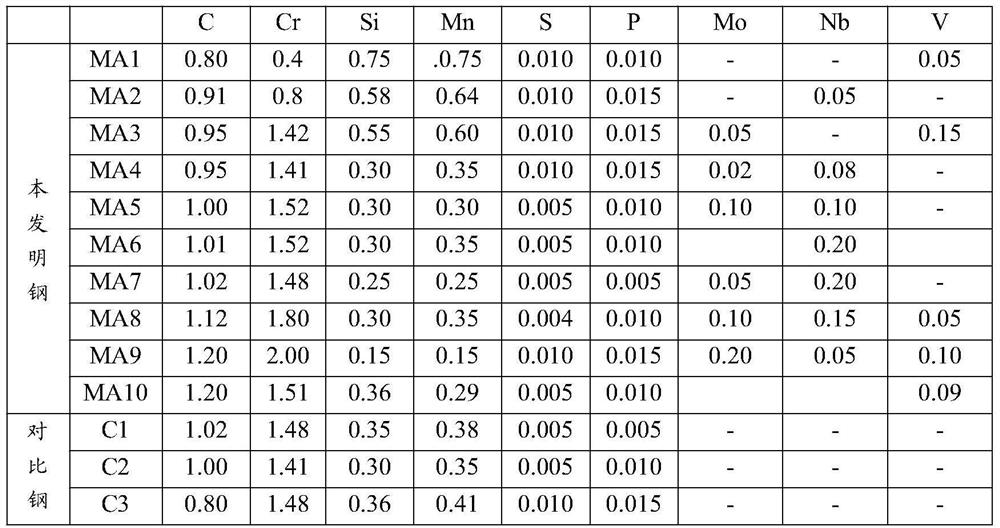

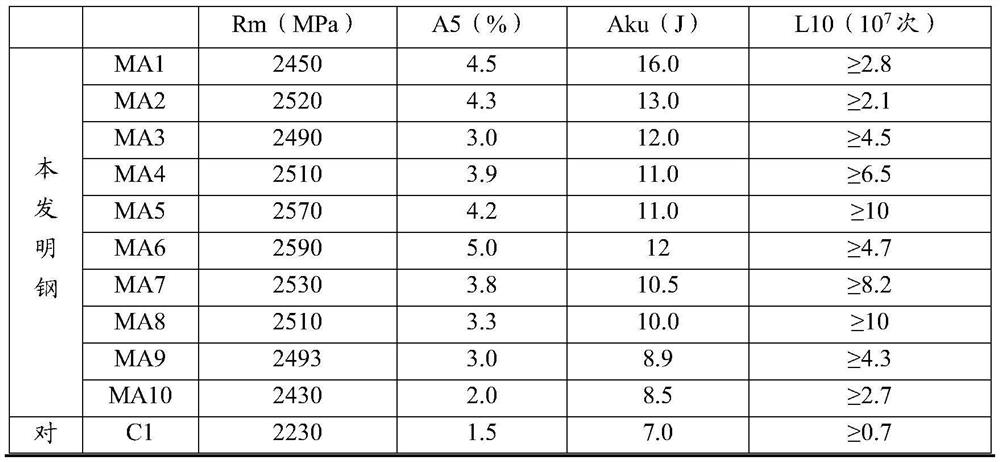

[0047] The steel of the present invention is smelted by a laboratory vacuum induction furnace, and the casting ingot shape is a 50kg round ingot. A total of 10 furnaces of steel are smelted for forging rod-shaped samples. The chemical composition is shown in Table 1. MA1-MA10 steels are microalloyed bearing steels of the present invention and C1-C3 comparison bearing steels (wherein the preparation method of round ingots is: C1 is GCr15 smelted in a laboratory vacuum induction furnace, C2 is GCr15 refined outside the furnace, and C3 is double Vacuum GCr15).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com