Thermal shrinkage and cold expansion type self-on-off cable sheath

A cable sheathing, cold expansion type technology, applied in the direction of insulated cables, power cables with shielding/conducting layers, cables, etc., can solve the problem of low transmission efficiency of cable power, inability to maintain cable temperature, high brittleness and easy damage and other problems, to achieve the effect of accelerating heat dissipation, ensuring the efficiency of power transportation, and improving the efficiency of dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

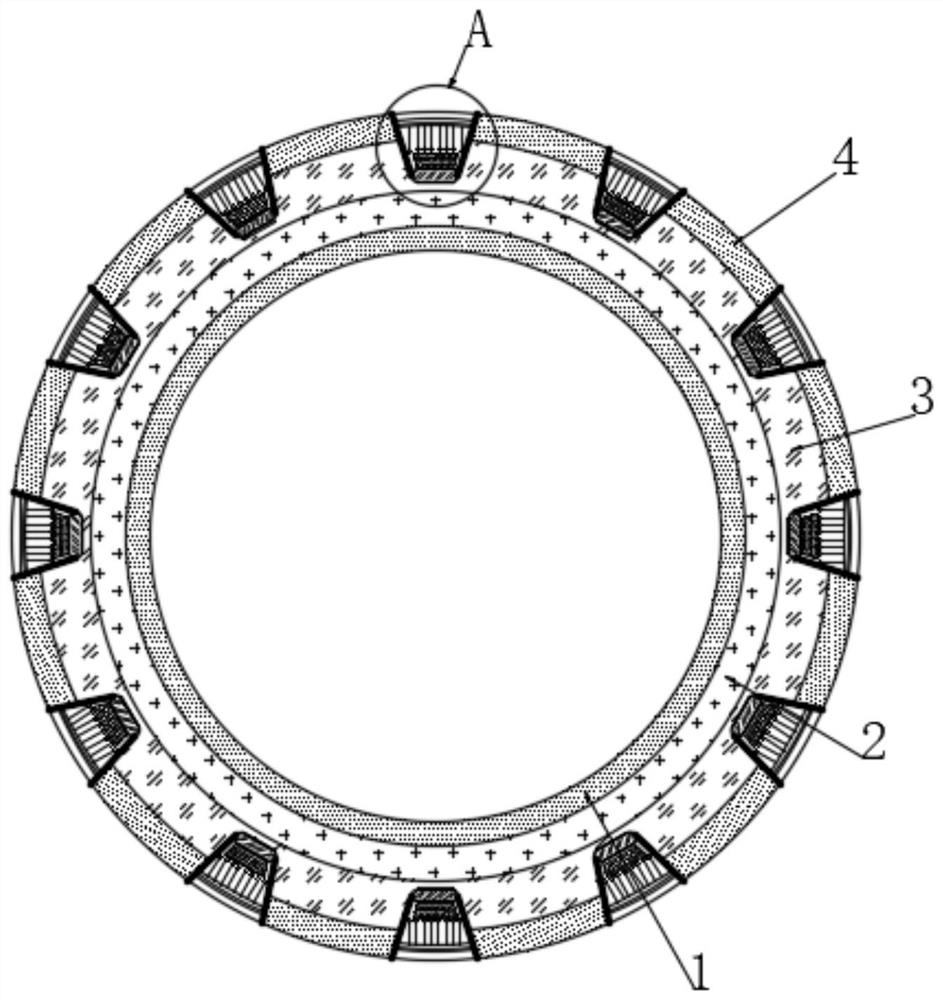

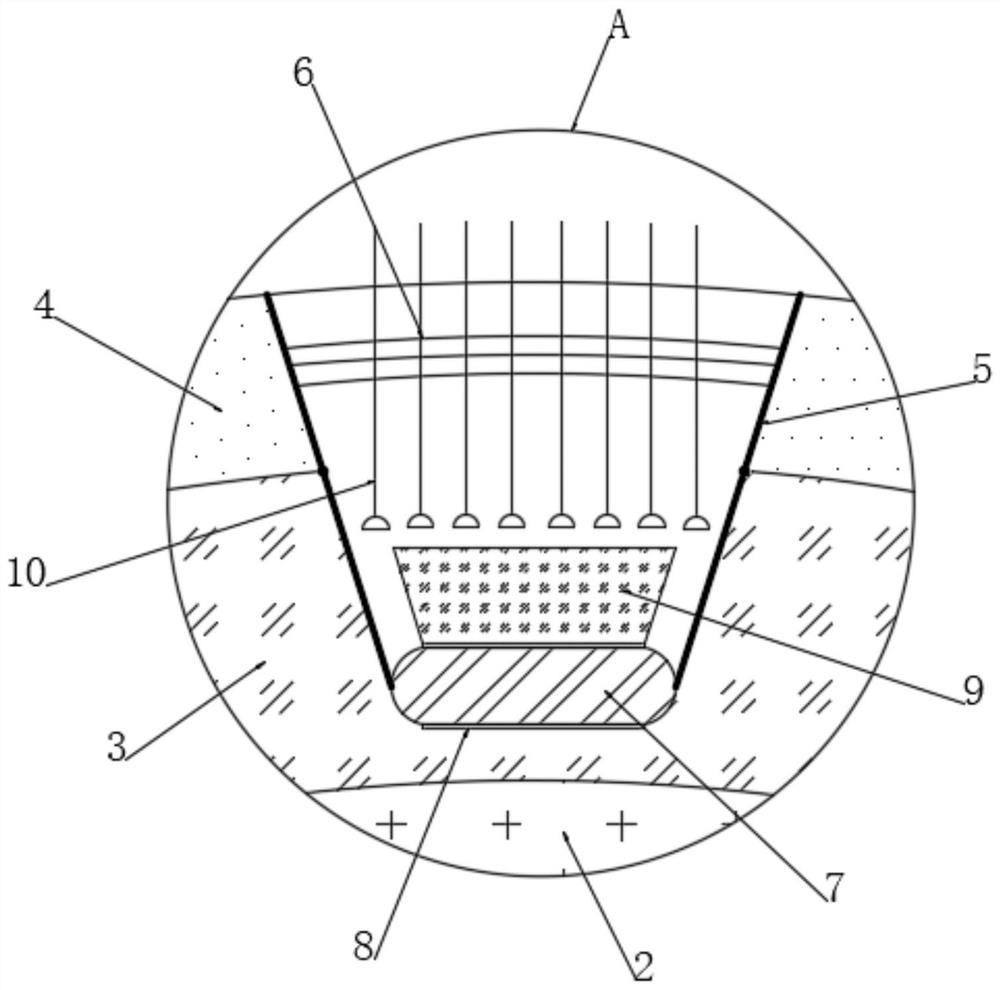

[0038] see figure 1 , a heat-shrinkable and cold-expandable self-switching cable sheath, comprising an inner insulating layer 1, a shielding layer 2, a protective interlayer 3 and an outer sheath 4, an inner insulating layer 1, a shielding layer 2, a protective interlayer 3 and an outer sheath 4 are distributed sequentially from the inside to the outside, and the adjacent two are fixedly connected to each other, and the inside of the protective interlayer 3 is inlaid with a plurality of uniformly distributed thermal shrinkage and cold expansion mechanisms.

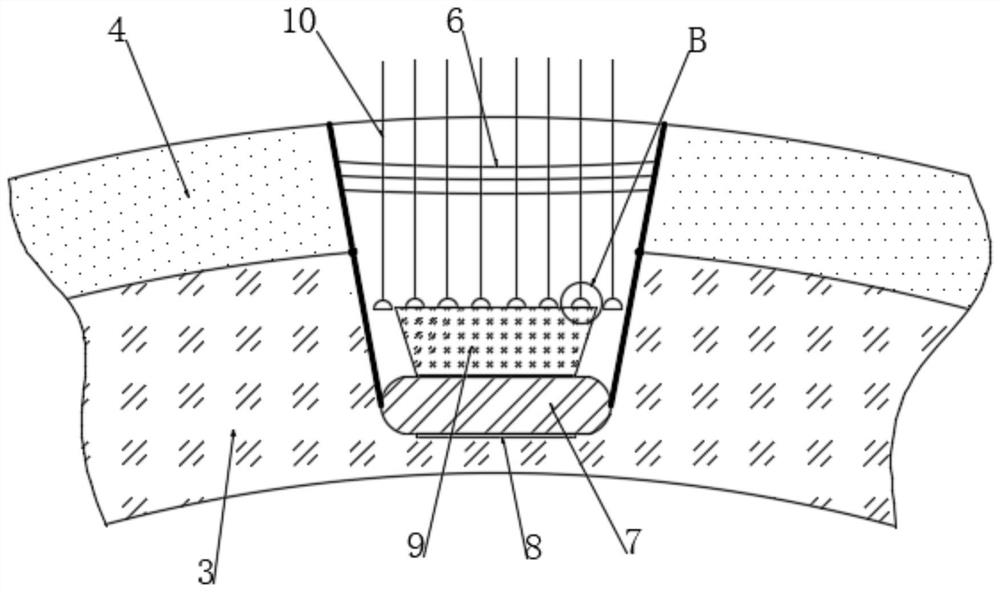

[0039] see figure 2 The end of the heat shrinkage and cold expansion mechanism away from the protective interlayer 3 is embedded in the outer sheath 4, the heat shrinkage and cold expansion mechanism includes a transverse temperature sensing rod 7 and a heat shrinking and cold expansion plate 5 fixedly connected to both ends of the transverse temperature sensing rod 7, two One end of the heat-shrinkable and cold-expandab...

Embodiment 2

[0043] The transverse temperature sensing rod 7 is made of an elastic sealing material filled with an inert gas with high thermal conductivity. The filling degree of the inert gas is saturated filling. At high temperatures, the expansion of the gas is faster than that of the solid material itself, which can further improve Sensitivity of the lateral temperature-sensing rod 7 to temperature changes.

[0044] The biggest difference between this embodiment and Embodiment 1 is the different settings of the transverse temperature-sensing rods 7 , and other contents are consistent with Embodiment 1.

[0045] Through the setting of the thermal shrinkage and cold expansion mechanism, when the external temperature is high, the transverse temperature sensing rod 7 is heated and expanded, so that the upper ends of the two thermal shrinkage and cold expansion plates 5 are close to each other in a state of "heat shrinkage". The on-off heat-conducting rod 10 is in contact with the heat-cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com