Preparation method of double-protein co-emulsified Pickering emulsion

A double protein, emulsion technology, applied in animal protein processing, vegetable protein processing, food science and other directions, can solve the problems of poor biocompatibility and biodegradability, surface activity is susceptible to pH, no food grade, etc. Uniform stability, low cost, optimized stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

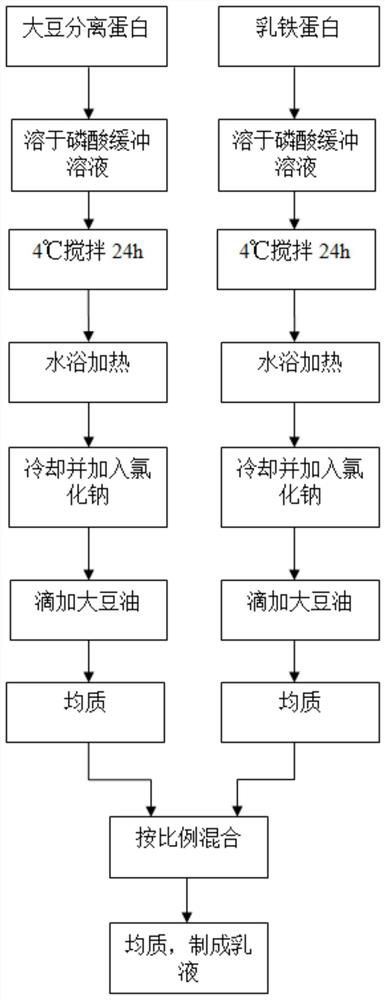

Image

Examples

Embodiment 1

[0033] (1) Soybean protein isolate powder was dissolved in 0.01M phosphate buffer solution (pH 7.0) to form a 6% (w / v) soy protein isolate solution, stirred magnetically at room temperature for 2 hours, and placed overnight at 4°C to fully hydrate the protein , adding sodium azide (0.02%, w / v) to inhibit microbial growth, subsequently, all samples were placed in a water bath at 95°C for 20 min, and then immediately cooled to room temperature in an ice-water bath, adjusted to pH 7.0, and 500 mM NaCl was added to increase Particle strength; then freeze-dried to obtain soybean protein isolate nanoparticles. Soybean oil was dropped into the soybean protein isolate nanoparticle (1% w / v) solution until the oil ratio was 0.6 (v / v), and dispersed with an IKA disperser at 10000rmp for 2min to obtain a soybean protein isolate emulsion.

[0034] (2) Dissolve lactoferrin powder in 0.01M phosphate buffer solution (pH 7.0) to make a 6% (w / v) lactoferrin solution, stir magnetically at room t...

Embodiment 2

[0037] The difference between this example and Example 1 is: (3) Mix the soy protein isolate emulsion and the lactoferrin emulsion according to the ratio of 2:8, and then use the IKA disperser to disperse at 10000rmp for 2min to obtain the double protein co-emulsified Pickering emulsion , and all the other operating steps are exactly the same as in Example 1. The emulsion prepared under this condition has uneven particle size and general stability.

Embodiment 3

[0039] The difference between this example and Example 1 is: (3) Mix the soybean protein isolate emulsion and the lactoferrin emulsion according to the ratio of 3:7, and then use the IKA disperser to disperse at 10000rmp for 2min to obtain the double protein co-emulsified Pickering emulsion , and all the other operating steps are exactly the same as in Example 1. The emulsion prepared under this condition has uniform particle size distribution and general stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com