Ultrasonic precision micro-fluidic chip based on nano motor array and implementation method thereof

A technology for microfluidic chips and implementation methods, applied in fluid controllers, chemical instruments and methods, laboratory appliances, etc., capable of solving the problems of weak sample processing capabilities, complex microfluidic chip structures, and single functions of microparticles of various sizes and other issues, to achieve good biological adaptability, high energy conversion efficiency, and low process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0036] An acoustically controlled microfluidic chip comprising an immobilized nanomotor array, the specific implementation of which is as follows:

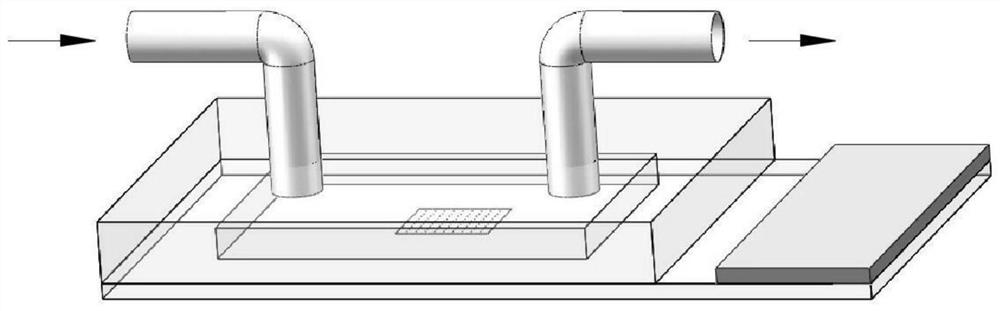

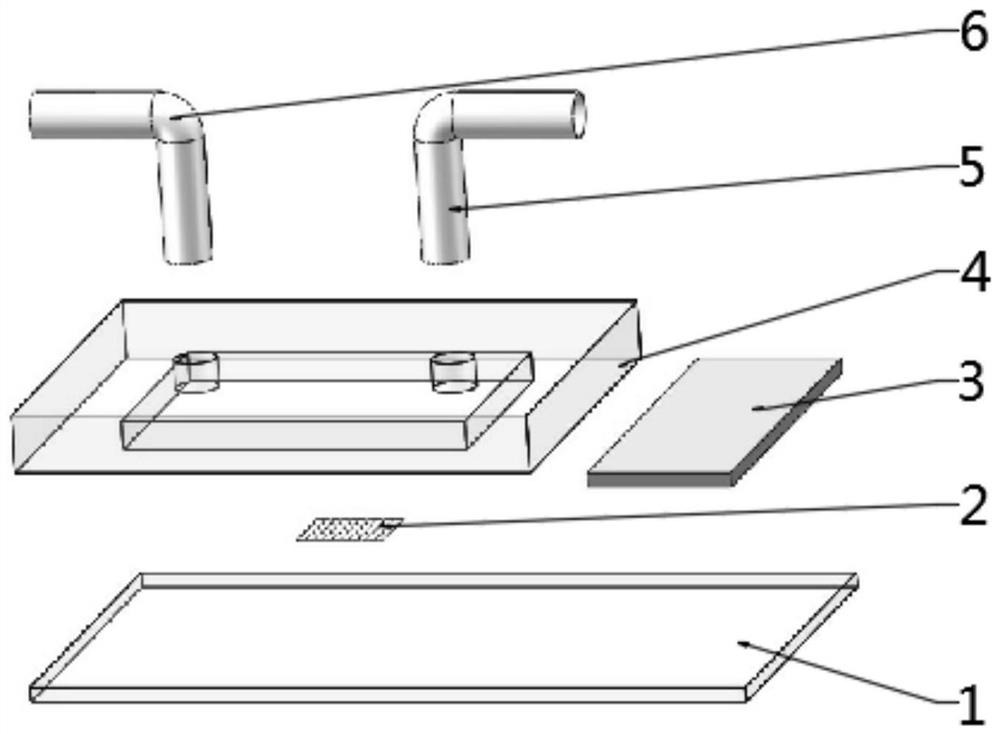

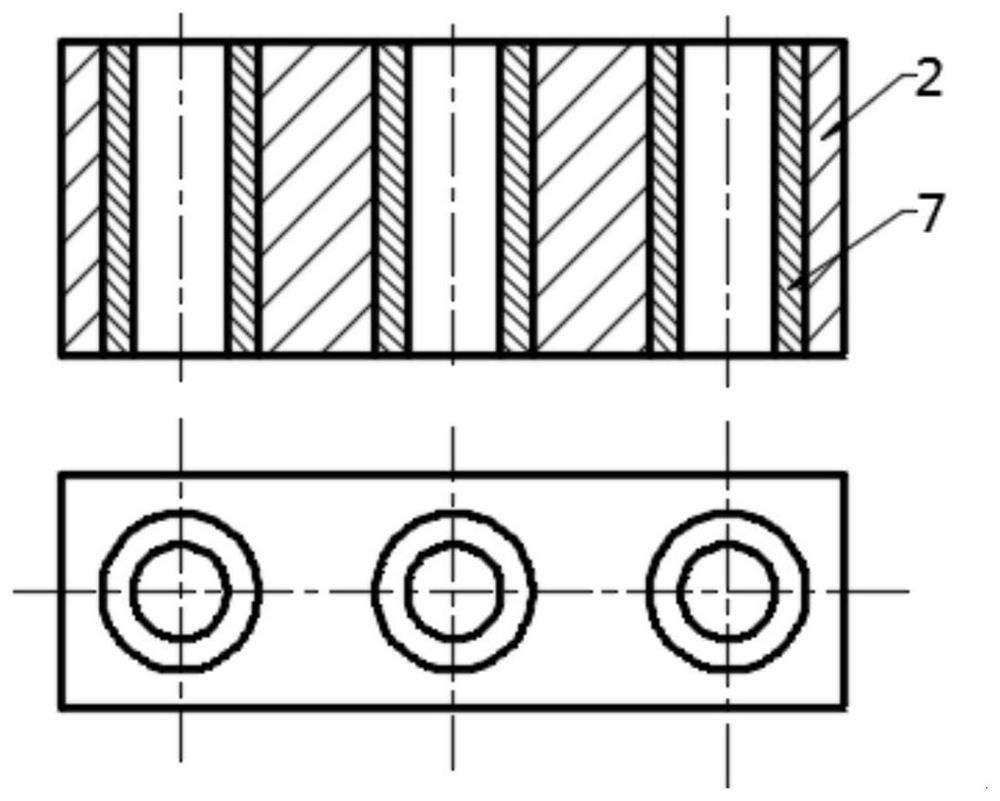

[0037] As shown in Figure 1(a) and Figure 1(b), the present invention discloses an ultrasonic precision microfluidic chip based on a nanomotor array, including a substrate 1, a nanomotor layer 2, a piezoelectric transducer 3, a cover Plate 4, liquid outlet pipe 5, liquid inlet pipe 6. Substrate 1 is made of quartz glass, with a size of 25×15×0.5mm; cover plate 4 is made of PDMS, with a size of 18×15×2mm; here piezoelectric transducer 3 is made of piezoelectric ceramic sheet (3), made of PZT-8, with a size of 15×5×0.5 mm; the substrate material of the immobilized nanomotor layer 2 is polycarbonate film. During installation, the piezoelectric ceramic sheet 3 is pasted on the upper edge of the quartz substrate 1, and at the same time connected to the electrode and grounded; the nanomotor solidified layer 2 is pasted on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com