Underground low-vacuum pipeline ultrahigh-speed maglev transportation system and construction method thereof

A transportation system and ultra-high-speed technology, applied in tunnel systems, sliding/floating railway systems, underground chambers, etc., can solve problems such as poor adaptability in mountainous areas, and achieve the effect of reducing demolition costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

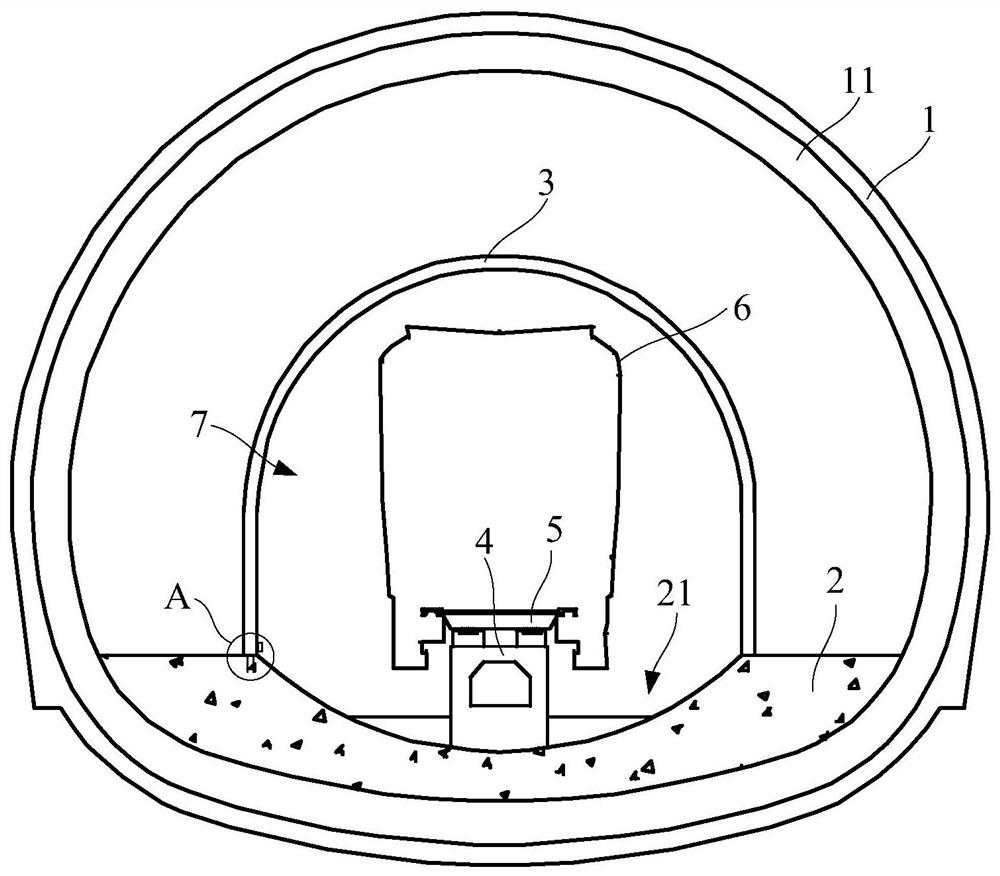

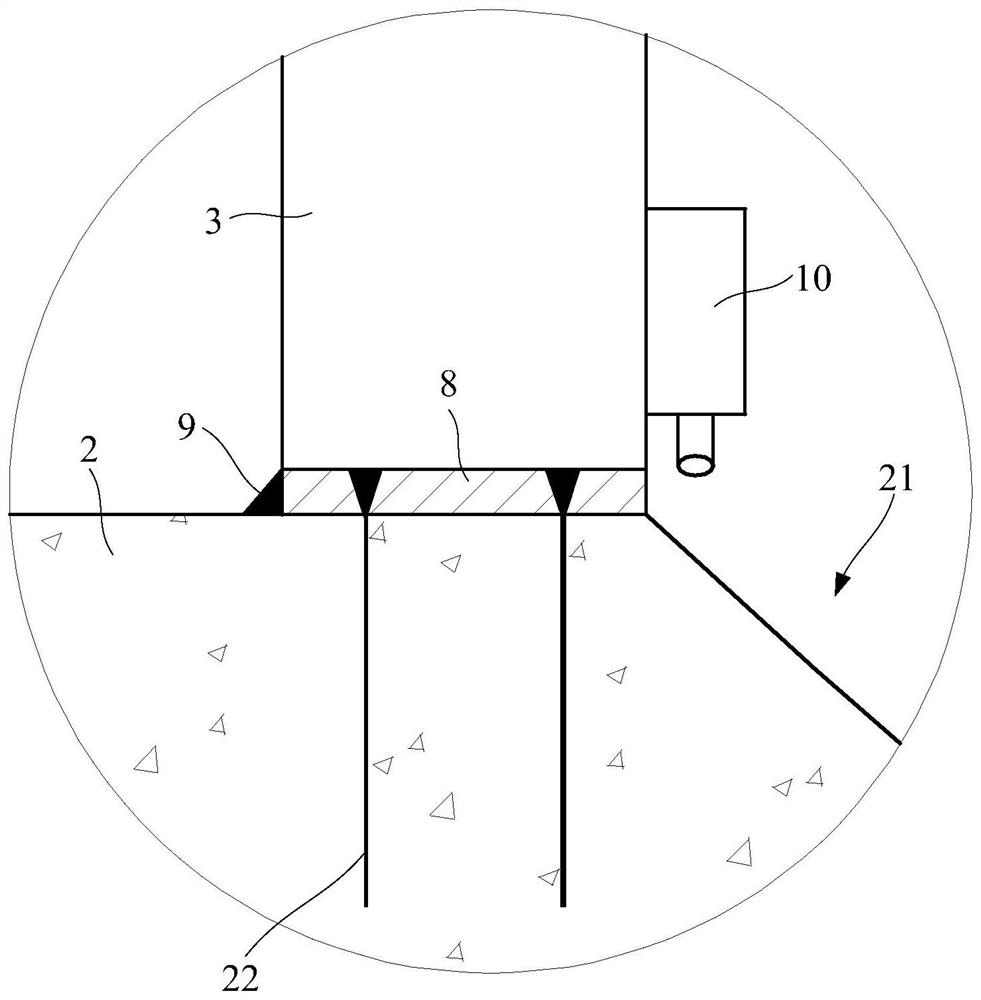

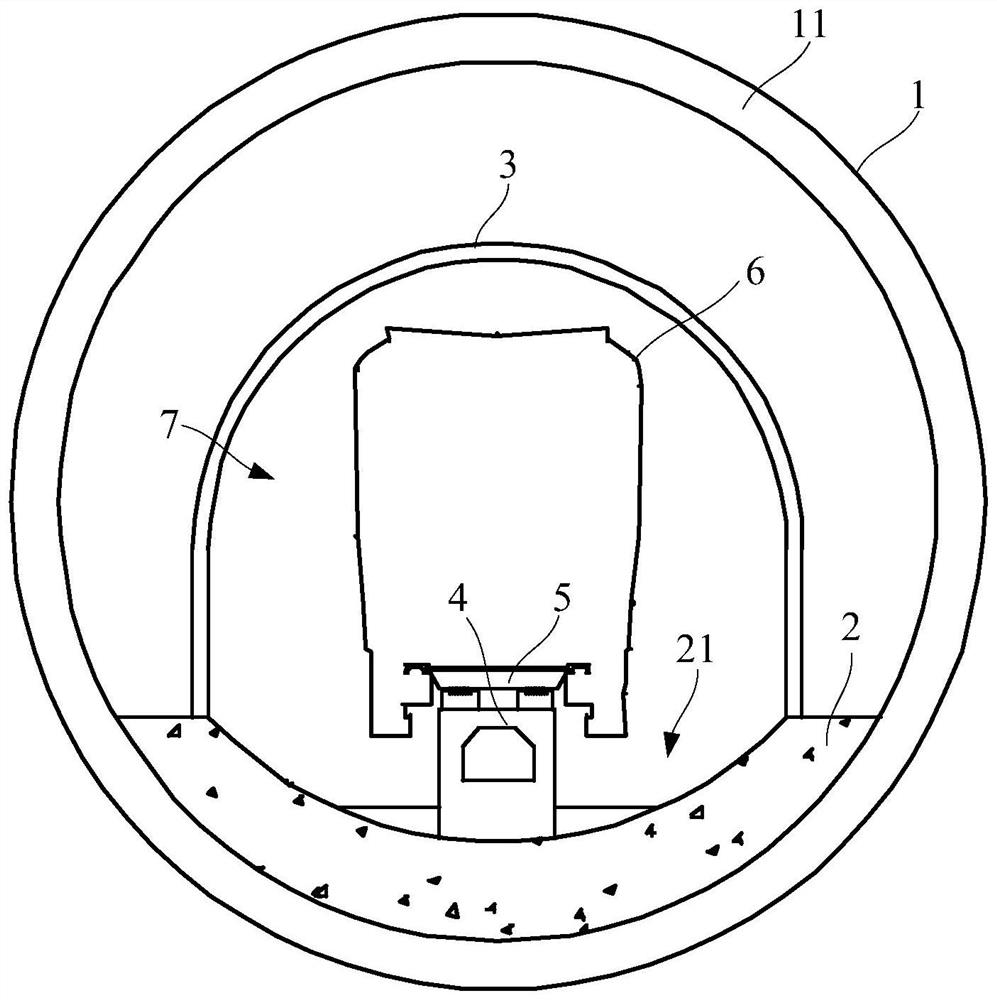

[0047] The embodiment of the present application provides an underground low-vacuum pipeline ultra-high-speed maglev transportation system for underground spaces. The maglev track 5 and the ultra-high-speed maglev train 6 adopt a structure of pipe-tunnel separation, wherein: figure 1 , image 3 and Figure 4 The structural schematic diagrams of the cross-section of the underground low-vacuum pipeline ultra-high-speed maglev transportation system in the underground tunnel 1 are respectively indicated;

[0048] The inner wall of the tunnel 1 is provided with a lining structure 11; the cross-sectional shape of the tunnel 1 can be horseshoe-shaped, circular or rectangular; figure 1 The cross-sectional shape of tunnel 1 in is horseshoe-shaped, image 3 The cross-sectional shape of tunnel 1 in is circular, Figure 4 The cross-sectional shape of the tunnel 1 in is a rectangle;

[0049] The supporting structure 2 is formed by pouring reinforced concrete on the lining structure 11...

Embodiment 2

[0063] In addition, the embodiment of the present application also provides a construction method of the underground low-vacuum pipeline ultra-high-speed maglev transportation system in any of the above-mentioned embodiments, such as Figure 5 As shown in the structure, the construction method includes the following steps:

[0064] In step S100, the tunnel 1 is constructed, and a lining structure 11 is formed on the inner wall of the tunnel 1; during the construction of the tunnel 1, it can be constructed by the mining method, the shield method, and the open cut method; the cross-sectional shape of the tunnel 1 can correspond to figure 1 in the horseshoe shape, image 3 circle in or Figure 4 The rectangular structure in; image 3 Tunnel 1 with a circular structure is suitable for construction by shield equipment; Figure 4 The tunnel 1 with a medium-rectangular structure is suitable for construction by cut and cover;

[0065] Step S200, constructing the support structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com