Intelligent and environment-protecting garbage classified recycling machine

A technology of garbage sorting and recycling machine, applied in the direction of garbage collection, trash can, waste collection and transfer, etc., can solve the problems of increased maintenance cost, increased production cost, different specifications, etc., to achieve easy maintenance and interchange, no waste Manufactured materials, the effect of a high degree of generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

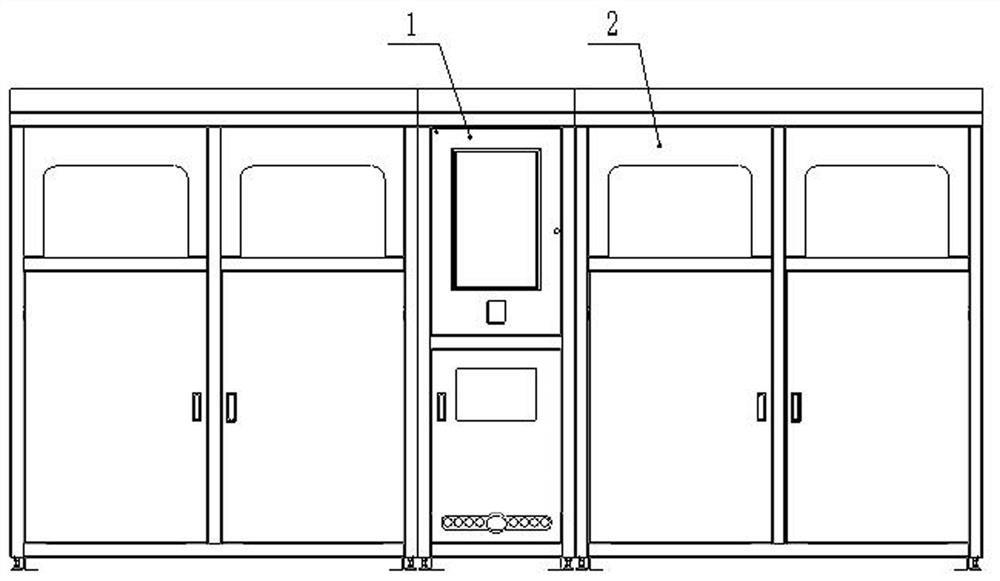

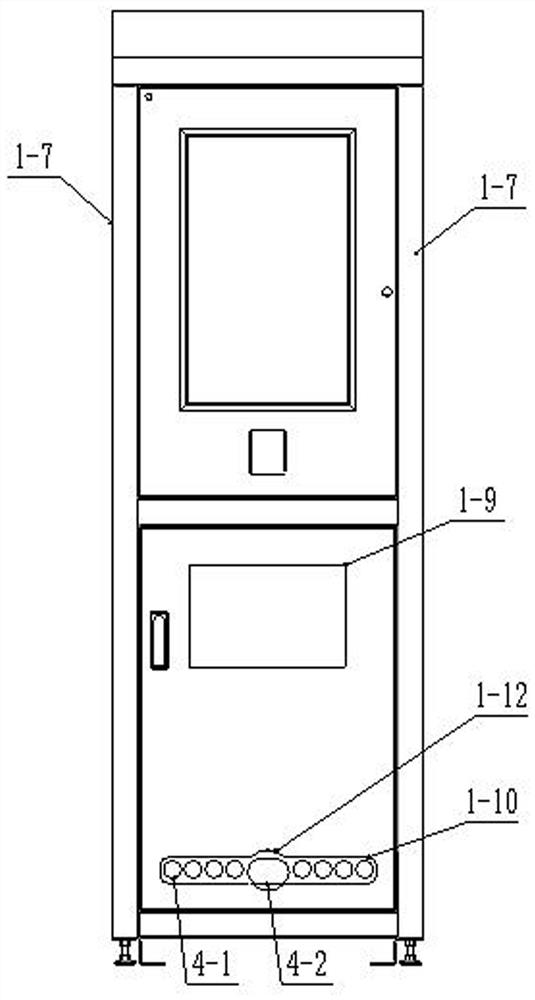

[0034] Depend on Figure 1-10 It can be seen that a kind of intelligent waste sorting and environmental protection recycling machine of the present invention comprises a main machine box body 1, a large box body 2, a recyclables sorting collection container 3, a harmful waste sorting collection container 4, a door opening mechanism 5, and a front end on the top of the main machine box body 1. There is a control panel 1-1, an open liquid crystal module 1-2 is installed on the control panel 1-1, a two-dimensional code scanner 1-3 is installed under the open liquid crystal module 1-2, and the distance between the control panel 1-1 and the host is The distance value of the front end of the cabinet 1 is B, the front eaves of the upper cover 1-4 of the host cabinet 1 protrude forward, the distance between the front eaves of the upper cover 1-4 and the front end of the host cabinet 1 is L, and the host cabinet The lower part of 1 is provided with hazardous waste delivery door 1-5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com