Curved tempered film and preparation process thereof

A preparation process and tempered film technology, applied in manufacturing tools, glass manufacturing equipment, branch equipment, etc., can solve the problems affecting the protection effect of the curved tempered film and the difficulty of attaching the curved tempered film, so as to improve the overall protection effect and improve the protection. effect, good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

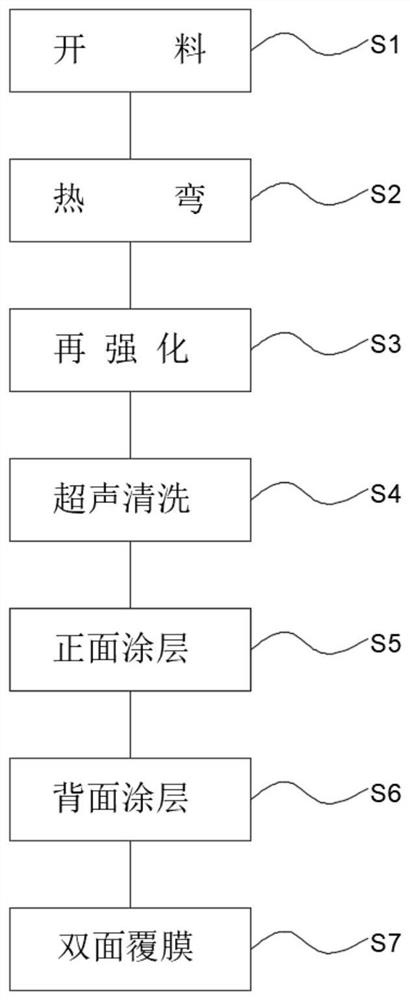

[0026] refer to figure 1 , which shows a flow chart of steps of an embodiment of a curved tempered film preparation process of the present invention, which may specifically include the following steps:

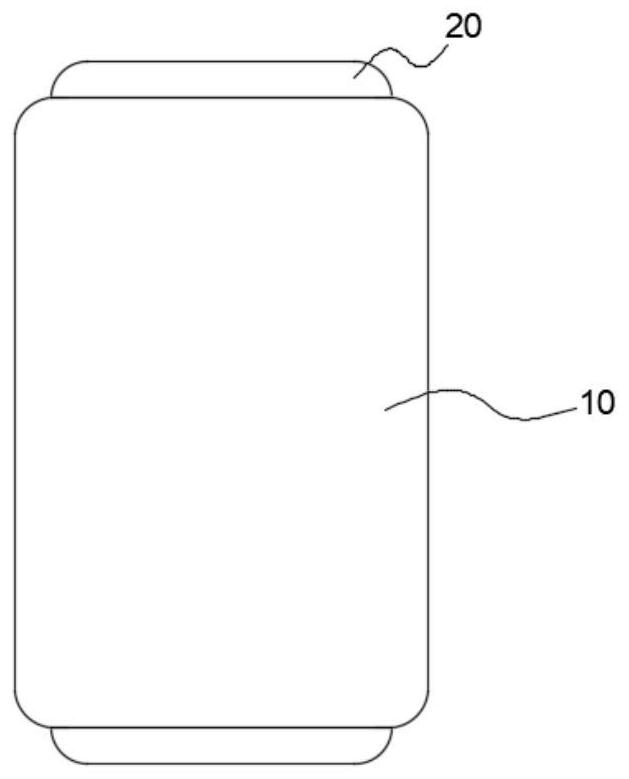

[0027] S1, material cutting, using a material cutting machine to cut the large substrate into small substrates according to the specifications, and using an adaptive mold to die-cut the small substrate into required substrates 10;

[0028] S2, hot bending, using a hot bending machine to form arc edges on the base material 10 through a hot bending process;

[0029] S3, strengthening again, putting the bent base material 10 into a tempering furnace for tempering treatment;

[0030] S4. Ultrasonic cleaning, using an ultrasonic clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com