Proportioning method of super-large-mixing-ratio fly ash cement stable base material and vibration stirrer

A technology of fly ash cement and base material, which is applied in the direction of cement mixing device, cement production, analysis materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A method for proportioning super-large-volume fly ash cement stabilized base materials, the method comprising the following steps:

[0069] Step 1: The gradation of the cement-stabilized base material should be based on the principle of dense skeleton and combined with the minimum void ratio to select the gradation range of the cement-stabilized base material;

[0070] Step 2: Determination of the optimal dosage of polycarboxylate high-performance admixture;

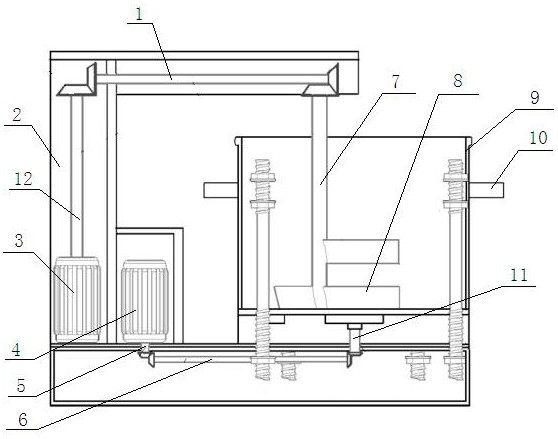

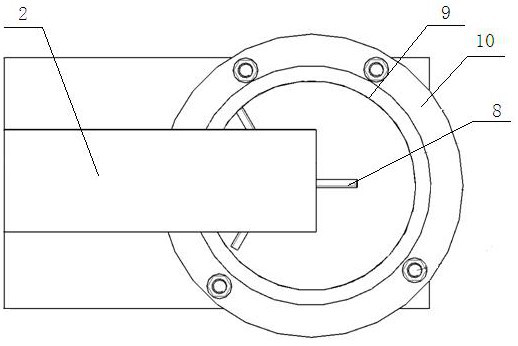

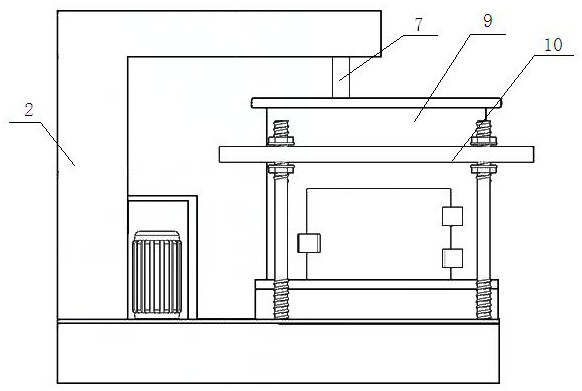

[0071] Step 3: Use a vibrating mixer to stir the cement to stabilize the base material and do a standard compaction test to determine the best moisture content and maximum density for the unconfined compressive strength test piece;

[0072] Step 4: Based on the optimum moisture content obtained in Step 3 and the corresponding maximum dry density, mold the unconfined compressive strength test piece according to the maximum dry density of 98%, and perform the unconfined compressive strength test;

[0073] Step 5: D...

Embodiment 2

[0075] According to the super-large-volume fly ash cement stabilized base material proportioning method described in Example 1, the specific process of the first step is: the gradation of the cement stabilized base material should be based on a compact skeleton and combined with a minimum void ratio In principle, multi-graded 19mm-26.5mm particle size aggregates are used to form the skeleton of the stress system, 9.5mm-19mm particle size aggregates are used to fill the gaps of the former, and 4.75mm-9.5mm particle size aggregates are used to fill 9.5mm-19mm particle size aggregates. The gaps formed by aggregates with a particle size of 0mm-4.75mm are filled with aggregates with a particle size of 0mm-4.75mm, and the gaps formed by aggregates with a particle size of 9.5mm-16mm are filled. ash) organically bond the aforementioned multi-graded aggregates together to form an integral pavement base cement stabilized base material, which mainly bears complex loads from road traffic f...

Embodiment 3

[0077] According to the super large amount of fly ash cement stabilized base material proportioning method described in embodiment 1 or 2, the specific process of described step 2 is: first do the compaction test of the cement stabilized base material without adding water reducing agent, and find Calculate the optimum water content, and determine the water consumption of the cement-stabilized base material mixed with the water-reducing agent according to the water-reducing rate of the high-performance water-reducing agent, and then do a compaction test to obtain the optimum water content of the cement-stabilized base material with the admixture And the maximum dry density, at this time, the dosage of high-performance superplasticizer is the optimal dosage, and the optimal dosage is 0.6%-1.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com