Poly4-methyl-1-pentene/silicone rubber thermoplastic elastomer, preparation and application thereof

A thermoplastic elastomer and silicone rubber technology, applied in the field of dynamic vulcanized thermoplastic elastomers, can solve the problems of low heat resistance and poor heat resistance, and achieve high heat resistance, high production efficiency, and high release properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

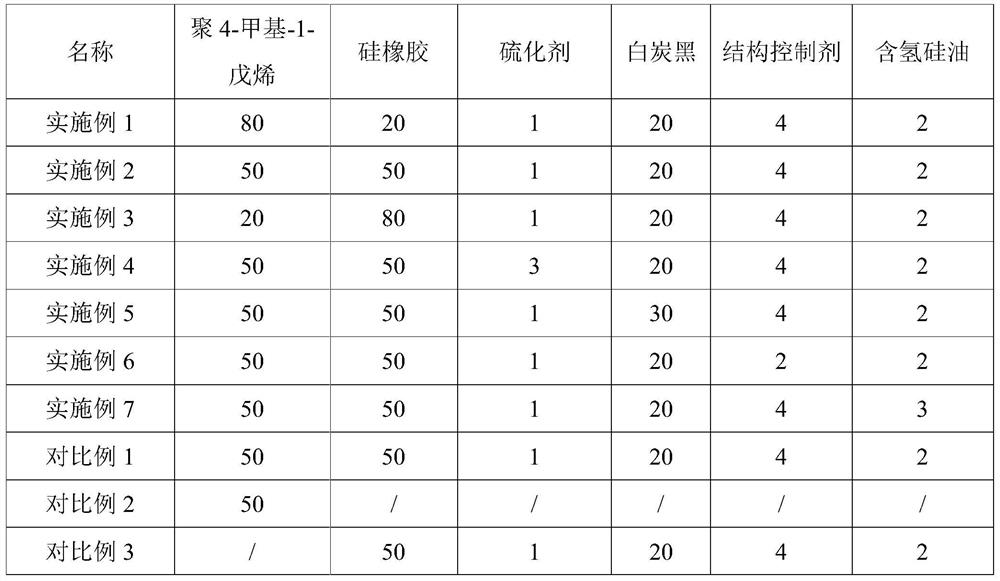

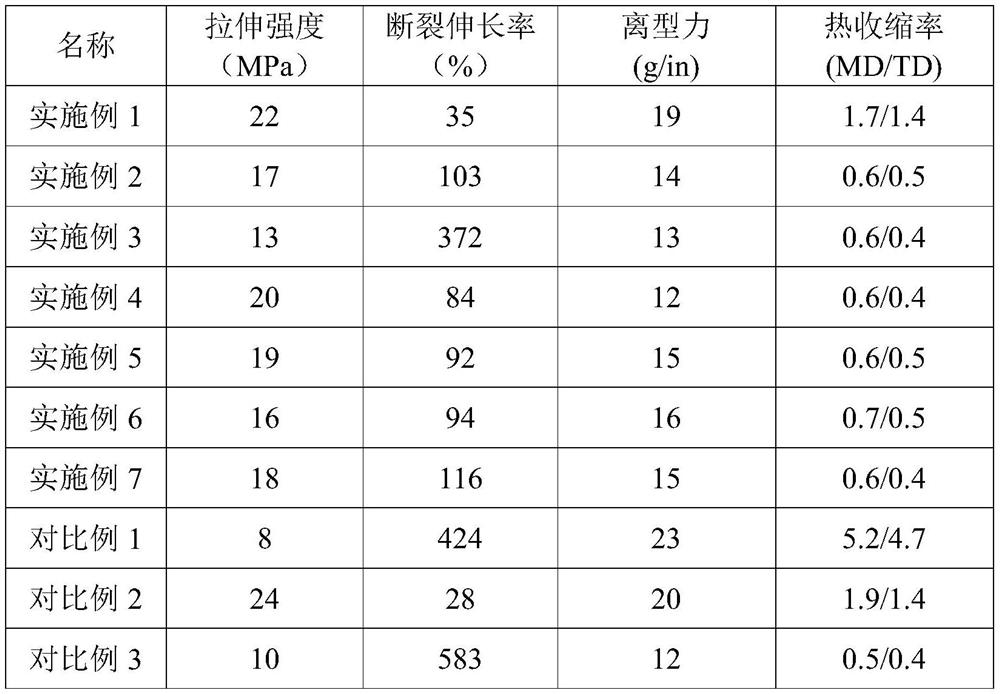

[0024] The raw material compositions of Examples 1-7 are shown in Table 1, and the amounts of each component in Table 1 refer to parts by mass.

[0025] The raw materials used in Table 1 are described as follows: poly-4-methyl-1-pentene is a copolymer containing 4-methyl-1-pentene structural unit, its Vicat softening point is 140-169 ° C, and the melt index is 20 -220g / 10min (5kg, 260°C). The silicone rubber is methyl vinyl silicone rubber, and the vinyl molar content in the methyl vinyl silicone rubber is 0.2%. The sulfiding agent was Karstedt's catalyst with a platinum concentration of 500 ppm. White carbon black is fumed white carbon black. The structure control agent is hydroxy silicone oil. Hydrogen silicone oil is high hydrogen silicone oil.

[0026] Preparation steps: (1) Mix the methyl vinyl silicone rubber, fumed silica, structure control agent hydroxyl silicone oil, and high hydrogen silicone oil in the formula in Table 1 in an internal mixer to obtain the mixed ...

Embodiment 8

[0045] The materials used, proportioning and preparation steps are the same as in Example 2, except that poly-4-methyl-1-pentene is a homopolymer, its Vicat softening point is 160-180°C, and the melt index is 20-180g / 10min ( 5kg, 260°C).

Embodiment 9

[0047] The materials, proportions and preparation steps used are the same as those in Example 2, except that the silicone rubber is phenylvinyl silicone rubber, and the vinyl molar content in the phenylvinyl silicone rubber is 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com