Household appliance color plate textured finish paint coating and preparation method thereof

A color plate and skin texture technology, which is applied in the field of color coated steel plate coatings, can solve the problems affecting the aesthetics of home appliance color plates and customer satisfaction, and achieve the effects of avoiding damage to the skin texture effect, small particle size, and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

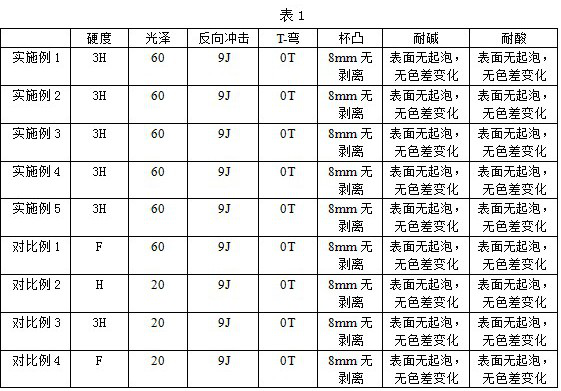

Examples

Embodiment 1

[0077] A kind of preparation method of home appliance color board skin pattern finish coating, comprises the following steps:

[0078] a. Soak 10kg FZ-EV120 aluminum powder in 8kg cyclohexanone for 3 hours;

[0079] b. Mix 55kg NL345 saturated polyester resin, 15kg CYMEL308 amino resin, 0.5kg R972 fumed silica and 0.4kg SRE-011 polysiloxane, and disperse at 1000r / min for 40 minutes;

[0080] c. Put the mixture dispersed in step b into a sand mill to grind once, and control the flow rate to 90 liters / hour;

[0081] d. Add the soaked aluminum powder in step a, 5kg of color paste, 1kg BYK057 defoaming aid and 0.5kg King N2500 acid catalyst to the ground mixture in step c while stirring.

Embodiment 2

[0083] A kind of preparation method of home appliance color board skin pattern finish coating, comprises the following steps:

[0084] a. Soak 5kg FZ-EV170 aluminum powder in 10kg S-150 aromatic hydrocarbon solvent for 5 hours;

[0085] b. Mix 60kg NL345 saturated polyester resin, 10kg CYMEL308 amino resin, 0.3kg R972 fumed silica and 0.8kg SRE-012 polysiloxane, and disperse at 1500r / min for 20 minutes;

[0086] c. Put the mixture dispersed in step b into a sand mill to grind once, and control the flow rate to 110 liters / hour;

[0087] d. Add the aluminum powder soaked in step a, 10kg color paste, 0.5kg BYK070 type defoaming aid and 1kg King N5225 type acid catalyst to the mixture ground in step c while stirring.

Embodiment 3

[0089] A kind of preparation method of home appliance color board skin pattern finish coating, comprises the following steps:

[0090] a. Soak 9kg FZ-EV170 aluminum powder in 8.5kg S-150 aromatic hydrocarbon solvent for 3.5 hours;

[0091] b. Mix 56kg NL385 type saturated polyester resin, 14kg CYMEL327 type amino resin, 0.45kg R974 type fumed silica and 0.5kg DEU ADD HM-6 type polysiloxane, and disperse at 1300r / min for 25 minute;

[0092] c. Put the mixture dispersed in step b into a sand mill to grind once, and control the flow rate to 95 liters / hour;

[0093] d. Add the aluminum powder soaked in step a, 6kg color paste, 0.8kg BYK057 defoaming aid and 0.6kg King N2500 acid catalyst to the ground mixture in step c while stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com