Composite material filled O-shaped metal plate damper and arrangement and parameter optimization method thereof

A technology of composite materials and dampers, which is applied in the field of construction, can solve the problems of poor global search ability, poor local search ability, and premature convergence of simulated annealing algorithms, so as to reduce the demand for lateral resistance, improve integrity, and improve shock absorption efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

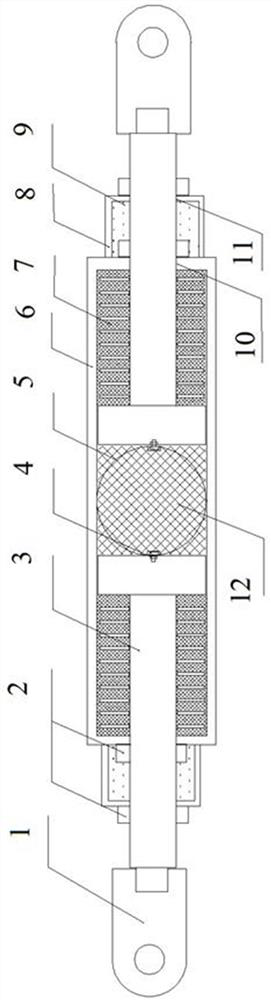

[0092] In this example, the material of the O-shaped metal plate is a memory alloy that meets the conditions according to the design requirements; its thickness and strength should meet the requirements that the piston rod move stably in the damper when the earthquake is impacted, and the O-shaped metal plate maintains deformation elasticity; The radius should be slightly smaller than the inner wall of the first piston steel sleeve.

[0093] The contact surface between the piston rod and the O-shaped metal plate is fixed horizontally by 3-6 bolts. The total cross-sectional area of the bolts is about 1 / 6 of the contact area, which ensures the integrity of the damper and does not damage the strength of the metal plate.

[0094] The inside and outside of the O-shaped metal plate are filled with foamed copper-polyurethane composite material to improve the working stability of the metal plate, and at the same time ensure the internal integrity of the damper when the metal plate is...

Embodiment 2

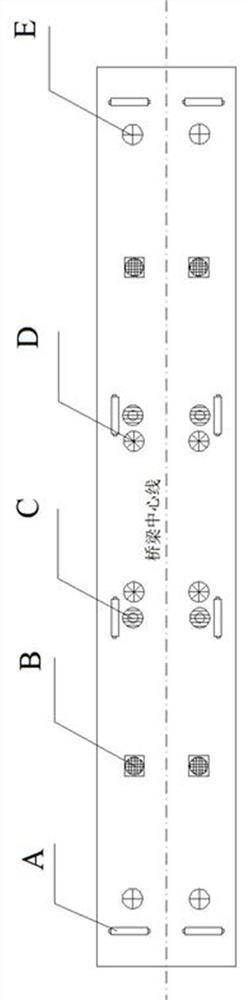

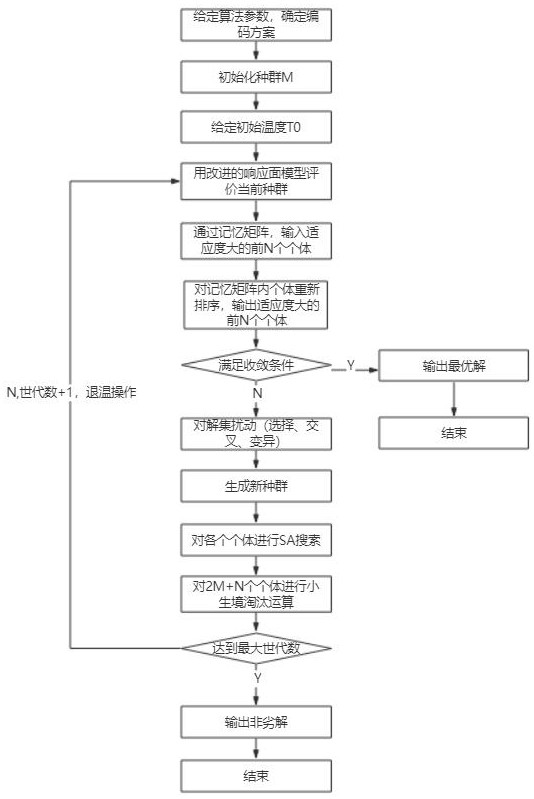

[0105] In parameter optimization, in this example, after determining the objective function, the method of optimizing multiple experimental factors with an orthogonal matrix is used to carry out the design of experiments (DOE), determine the influence of the experimental factors on the objective function, and then determine the design variables, constraints condition. DOE can determine the optimal level combination under all factors and corresponding level conditions through a small number of experiments.

[0106] When determining the objective function, take the longitudinal displacement of the beam end of the main beam as the objective function through DOE, and select as many foam copper-polyurethane composite materials as possible to fill the O-shaped metal plate damper process parameters, such as foam copper-polyurethane composite material porosity, foam In the copper-polyurethane composite material, the polyurethane filling integral, the thickness of the O-shaped metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com