Grading method and system suitable for recycled asphalt mixture, medium and equipment

A technology for asphalt mixture and recycled asphalt, applied in computer materials science, informatics, instruments, etc., can solve problems such as lack of theoretical basis for the determination of the lower limit range, construction workability is not as good as continuous grading, oil flooding, etc. Theoretical guiding significance and engineering practical application value, improving the ability to resist low temperature cracking and water damage, and improving the effect of relatively brittle and hard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Aiming at many problems in the application process of the grading curve mentioned in the prior art, especially the risk of damage in the recycled asphalt mixture, Example 1 of the present disclosure provides a gradation suitable for the recycled asphalt mixture method.

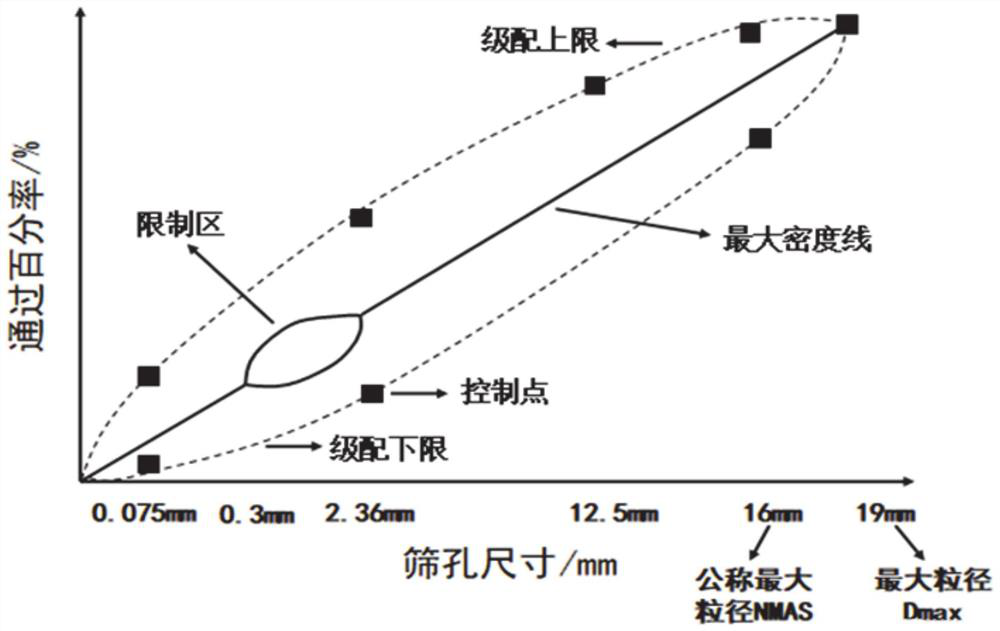

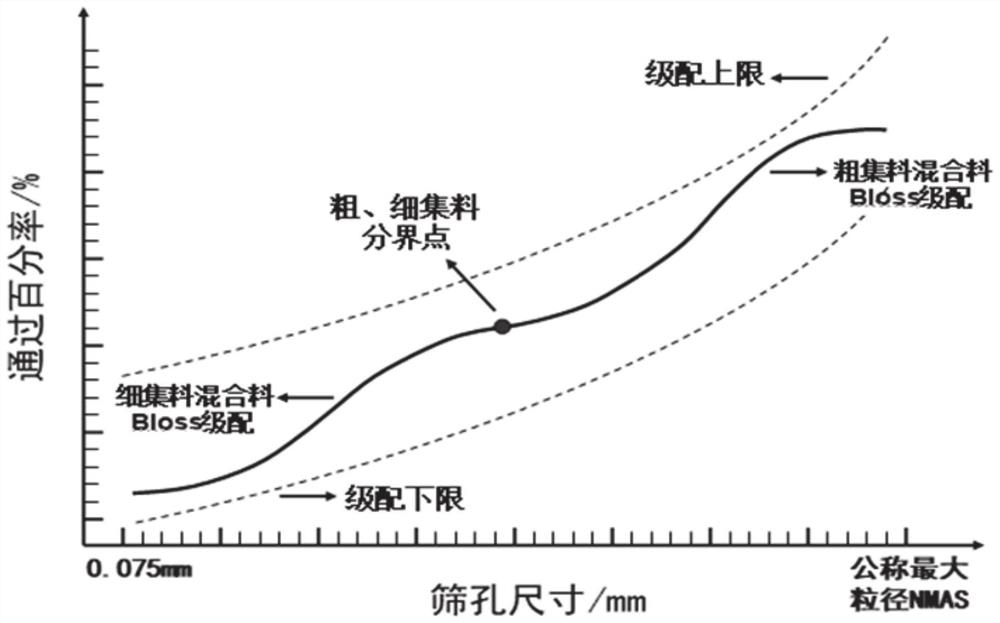

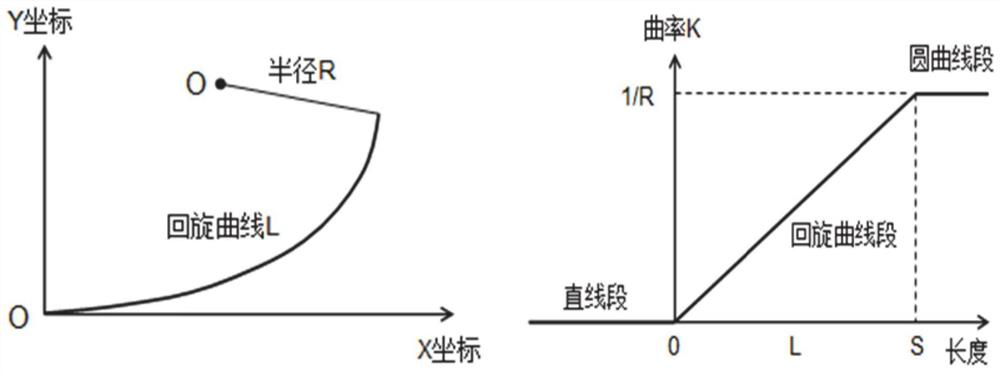

[0067] The grading method provided in this example proposes to separate the coarse and fine aggregate mixtures for gradation design; at the same time, the coarse and fine aggregate mixtures adopt a Bloss gradation with a continuous curve and a continuous rate of change of the curve. The model is constructed, and by changing the passing percentage P value of the three key sieve holes, the (regenerated) asphalt mixture of the suspension dense structure type and the skeleton dense structure type can be constructed respectively; finally, the volume characteristic parameters (VCA DRC , VCA mix , VV, etc.) and road performance characteristics (rutting slab dynamic stability DS, trabecular bending failure str...

Embodiment 2

[0130] Embodiment 2 of the present disclosure provides a grading system suitable for recycled asphalt mixture, including:

[0131] The sieve hole determination module is configured to: determine the minimum sieve hole diameter and pass rate, the nominal maximum sieve hole diameter and pass rate, and the sieve hole diameter at the boundary point of coarse and fine aggregates according to the RAP milling and planing screening results and the preset road surface performance index requirements and pass rate;

[0132] The preliminary gradation curve acquisition module is configured to obtain the gradation curves of the coarse aggregate mixture and the fine aggregate mixture respectively according to the Blaus gradation curve model, and obtain the gradation by using the determined sieve hole diameter and passing rate The parameters of the curve model to obtain the preliminary recycled asphalt mixture grading curve;

[0133] The mixture grading module, configured to: VCA according t...

Embodiment 3

[0136] Embodiment 3 of the present disclosure provides a medium on which a program is stored, and when the program is executed by a processor, the steps in the grading method applicable to recycled asphalt mixture as described in Embodiment 1 of the present disclosure are implemented, the The steps are:

[0137] According to the RAP milling and screening results and the preset road surface performance index requirements, determine the minimum sieve hole diameter and pass rate, the nominal maximum sieve hole diameter and pass rate, the sieve hole diameter and pass rate at the boundary point of coarse and fine aggregates;

[0138] According to the Blaus gradation curve model, the gradation curves of coarse aggregate mixture and fine aggregate mixture are respectively obtained, and the parameters of the gradation curve model are obtained by using the determined sieve aperture and passing rate, and the preliminary recycled asphalt mixture is obtained. material grading curve;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com