Semiconductor device and preparation method thereof

A semiconductor and device technology, which is applied in the field of semiconductor devices and their preparation, can solve the problems of high preparation cost and unfavorable laser promotion, and achieve the effects of reducing preparation cost, reducing preparation difficulty, and preventing transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

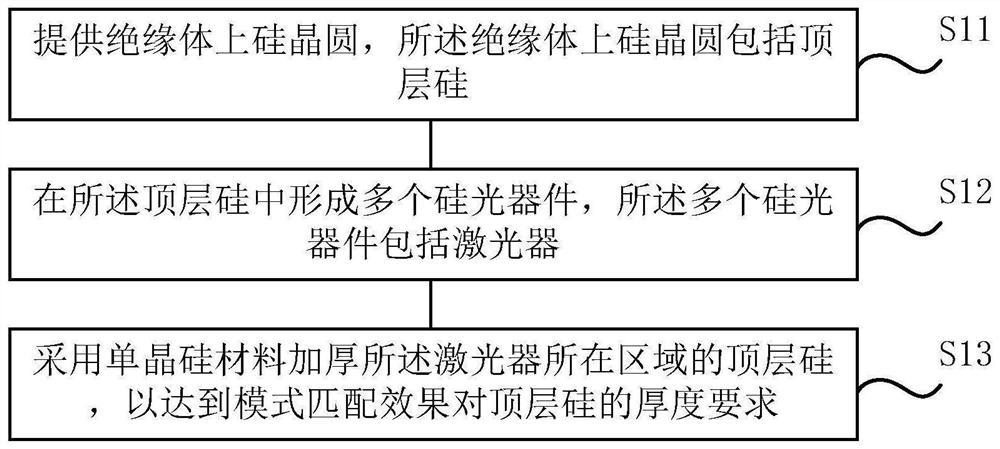

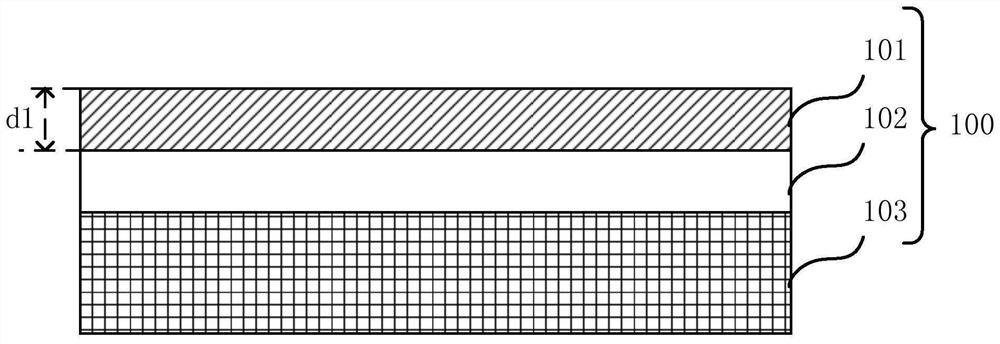

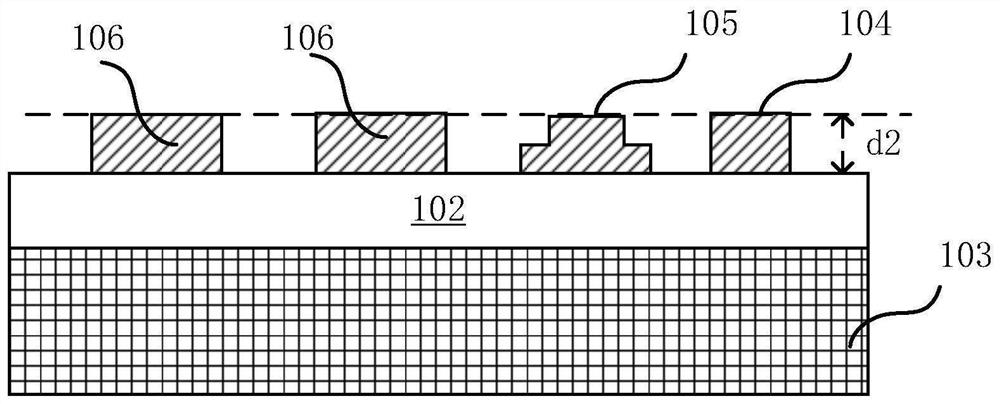

[0033] In this specific embodiment, a method for manufacturing a semiconductor device is provided, including the following steps: S11 provides a silicon-on-insulator wafer 100, the silicon-on-insulator wafer 100 includes a top-layer silicon 101, please refer to figure 2 ; S12 forms a plurality of silicon photonic devices in the top layer silicon 101 (the silicon photonic devices include all components shown in labels 104, 105, and 106), and the silicon photonic devices include a laser 106, please refer to here image 3 ; S13 uses single crystal silicon material to thicken the top layer silicon 101 in the region where the laser is located, to achieve the mode matching effect on the thickness requirements of the top layer silicon 101, please refer to here Figure 7 .

[0034] In this specific embodiment, in the manufacturing method of the semiconductor device, the top layer of silicon 101 in the area where the laser 106 is located is thickened by using single crystal silicon ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com