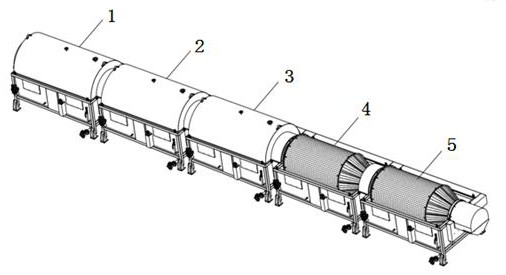

Device for infiltrating and stripping lithium battery anode and cathode materials and working method thereof

A technology of positive electrode material and negative electrode material, applied in the field of lithium battery positive and negative electrode material recycling, can solve problems such as personal safety and environmental pollution hazards, personal safety hazards, and personal safety hazards, so as to reduce labor intensity, avoid pollution, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

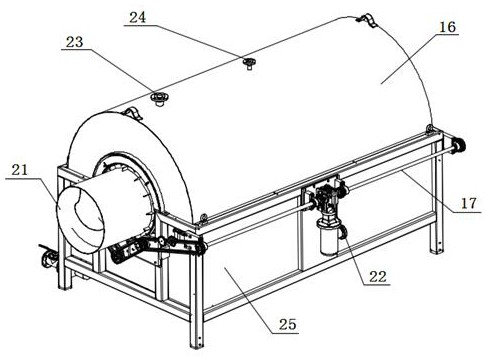

Method used

Image

Examples

Embodiment 1

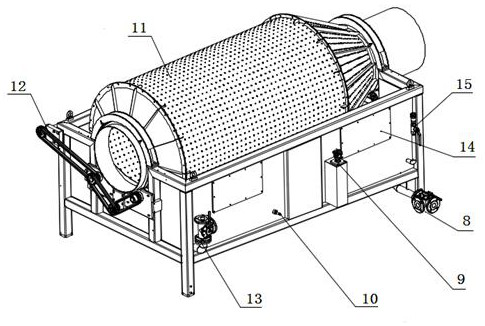

[0043] S1, the cut and shredded battery is first transported to the negative electrode material stripping reactor 1;

[0044] S2, the strong alkaline mixed stripping solution in the negative electrode material stripping reactor 1 reacts with the scrap battery, and the scrap battery reciprocates through the internal screw mechanism of the reactor for about 15 minutes and fully contacts with the strong alkaline mixed solution to infiltrate the reaction, so that the negative electrode material is removed from The battery block is peeled off and melted into the solution and left in the reactor. The screw mechanism of the reactor runs for 1 minute, so the scrap battery reciprocates 7.5 times with the screw mechanism, and the reaction in the reactor produces a small amount of hydrogen and a high temperature of about 80 degrees Celsius. Evaporate the solution into the air, and the mixed gas is pumped out from the upper part of the reactor to the rear settling box for cooling and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com