Aluminum alloy strip compression micro-cutting machine

A technology of micro-cutting machine and aluminum alloy, applied in the field of aluminum alloy processing, can solve the problems of inaccurate aluminum alloy cutting, inaccurate installation size of aluminum alloy doors and windows, and burrs generated by manual grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

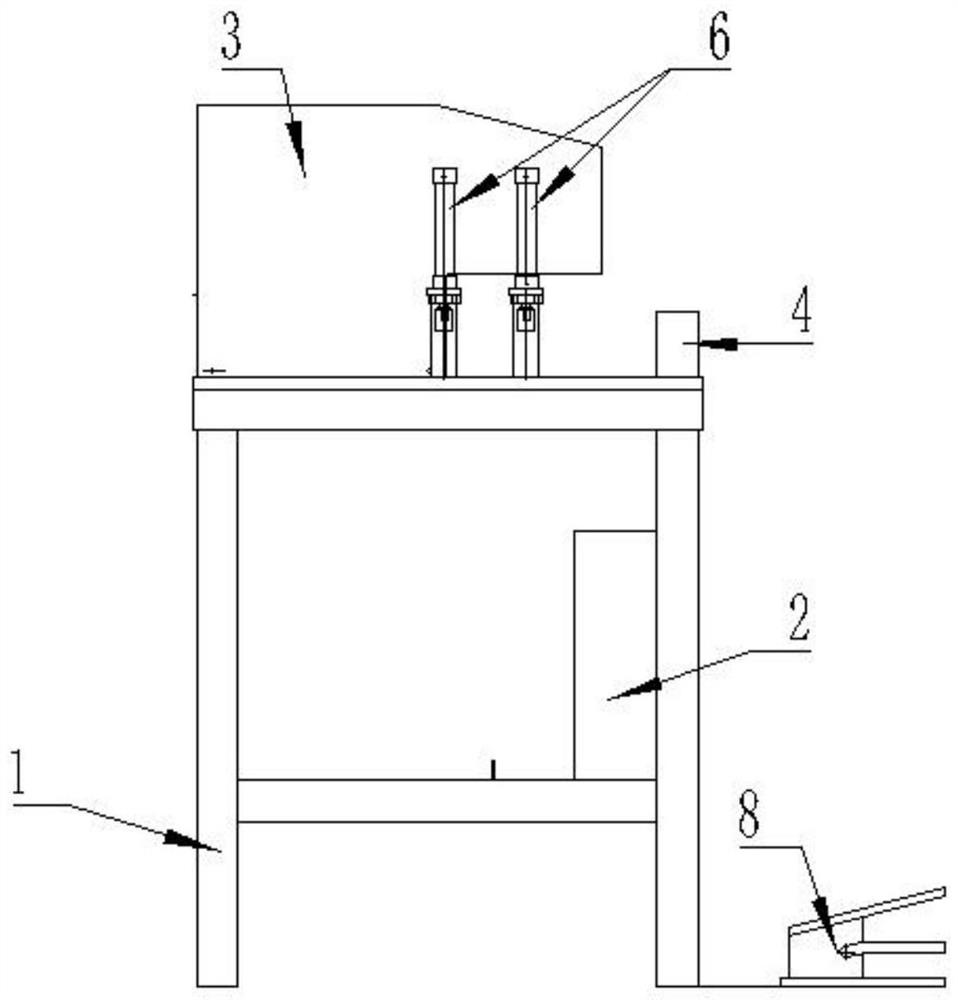

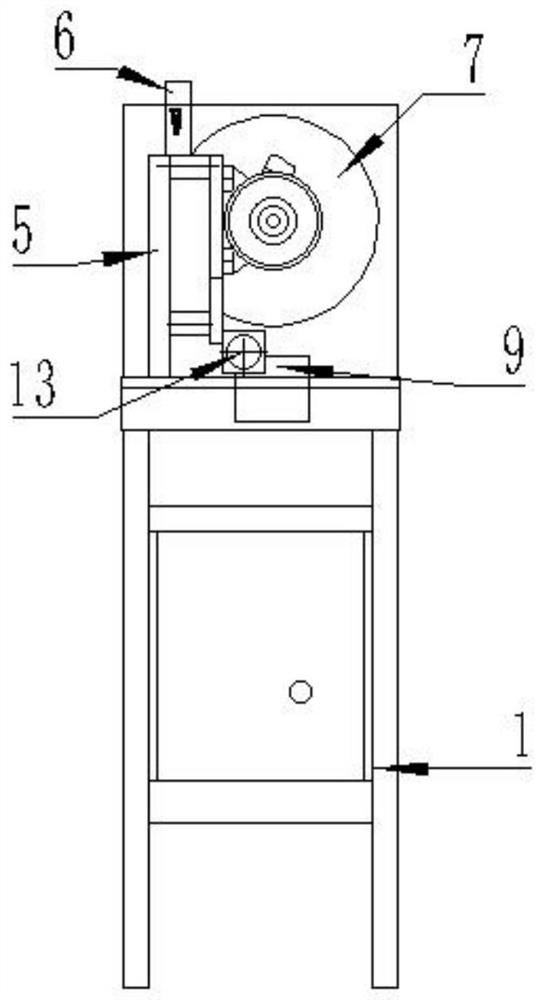

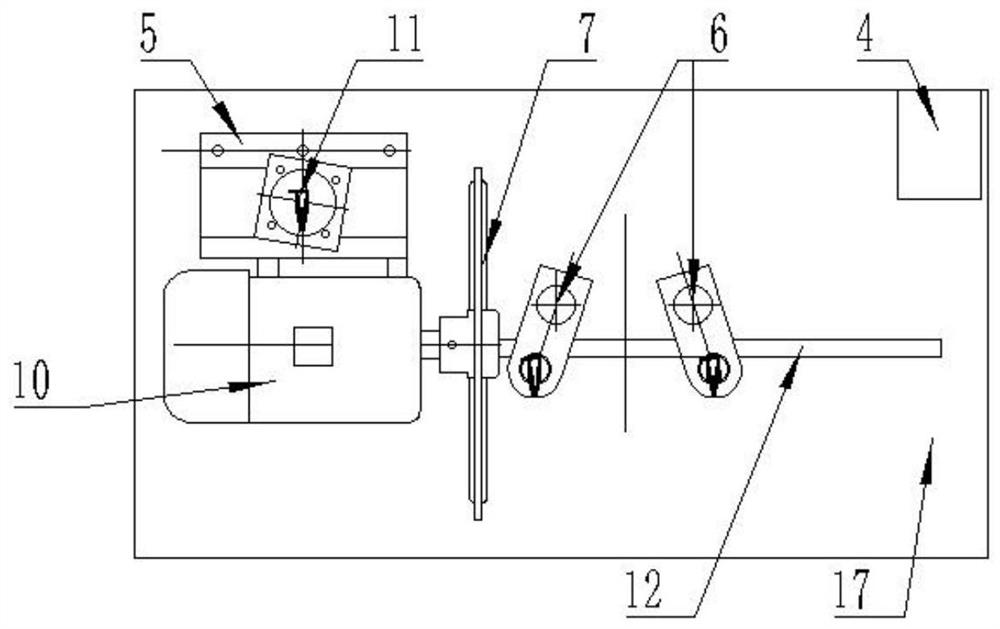

[0028] like Figure 1-Figure 6 As shown, the present invention discloses a micro-cutting machine for aluminum alloy strips, including a workbench 17, on which a retaining strip 12 is arranged, and on the workbench 17, several aluminum strip pressing devices are arranged. The aluminum bar pressing device is arranged above the retaining bar 12 , and the aluminum bar pressing device includes a cylinder 6 . The cylinder 6 is connected with a high-pressure air source, and the cylinder 6 is driven by the high-pressure air source. The movable end of the cylinder 6 is provided with a pressing block, and the pressing block is made of flexible plastic or rubber.

[0029] The bar 12 is used to locate the lateral position of the aluminum bar; the workbench 17 is provided with several mounting holes for the bar 12 and the mounting holes for installing the cylinder 6, so that the positions of the cylinder 6 and the bar 12 can be adjusted, Realize the cutting of aluminum strips at differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com