Full-floating type rear axle housing assembly half axle sleeve oil seal journal surface machining process

A half-shaft casing and surface processing technology, applied in the field of oil seal journals, can solve the problems of waste of production resources, lack of testing, hardness effects, etc., and achieve the effect of improving fatigue strength, avoiding quenching treatment, and ensuring hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

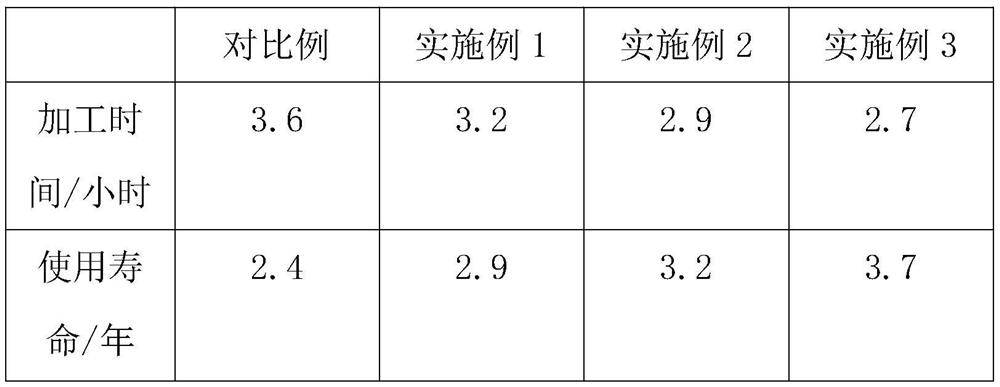

Examples

Embodiment 1

[0029] Step 1: Basic treatment of the surface of the journal of the oil seal: Use a soft clean cloth to clean the surface of the journal comprehensively, and conduct a comprehensive inspection on the surface after cleaning to determine the protruding particles on the surface of the journal, and then check the convex particles on the surface of the journal. Metal particles are removed for removal;

[0030] Step 2: Deep grinding treatment on the surface of the journal: Use a grinder to grind the horizontal lines on the surface of the journal first. After the grinding operation, use the grinder to grind the vertical lines on the surface of the journal. When both are polished, the qualified product records;

[0031] Step 3: Oiling operation on the journal surface: each time use a soft cloth with a surface area of 100 square centimeters to absorb 20 grams of lubricating oil, and evenly oil the journal surface. After oiling, perform a static inspection of the basic dimensions of t...

Embodiment 2

[0036] Step 1: Basic treatment of the surface of the journal of the oil seal: Use a soft clean cloth to clean the surface of the journal comprehensively, and conduct a comprehensive inspection on the surface after cleaning to determine the protruding particles on the surface of the journal, and then check the convex particles on the surface of the journal. Metal particles are removed for removal;

[0037] Step 2: Deep grinding treatment on the surface of the journal: Use a grinder to grind the horizontal lines on the surface of the journal first. After the grinding operation, use the grinder to grind the vertical lines on the surface of the journal. When both are polished, the qualified product records;

[0038] Step 3: Oiling operation on the journal surface: each time use a soft cloth with a surface area of 125 square centimeters to absorb 25 grams of lubricating oil, and oil the journal surface evenly. After oiling, perform a static inspection of the basic dimensions of t...

Embodiment 3

[0043] Step 1: Basic treatment of the surface of the journal of the oil seal: Use a soft clean cloth to clean the surface of the journal comprehensively, and conduct a comprehensive inspection on the surface after cleaning to determine the protruding particles on the surface of the journal, and then check the convex particles on the surface of the journal. Metal particles are removed for removal;

[0044] Step 2: Deep grinding treatment on the surface of the journal: Use a grinder to grind the horizontal lines on the surface of the journal first. After the grinding operation, use the grinder to grind the vertical lines on the surface of the journal. When both are polished, the qualified product records;

[0045] Step 3: Oiling operation on the journal surface: each time use a soft cloth with a surface area of 150 square centimeters to absorb 30 grams of lubricating oil, and evenly oil the journal surface. After oiling, perform a static inspection of the basic dimensions of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com