Method for preparing porous aluminum alloy by using hollow microspheres

A hollow microsphere, aluminum alloy technology, applied in the field of metal functional materials, can solve the problem of removing pore-forming agent, etc., and achieve the effects of low cost, simple process and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

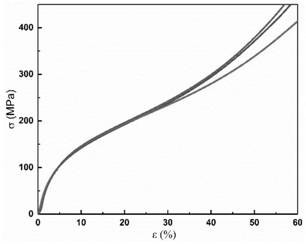

[0039] Alumina hollow microspheres with an outer diameter of 50 μm and a wall thickness of 2 μm were used as pore-forming agents. Under argon protection, the alumina hollow microspheres and 25 μm 2A12 aluminum alloy powder were mixed in a volume ratio of 3:7 in a glove box. Put it into a closed container, and then fully mix the materials to obtain uniformly mixed alumina hollow microspheres + aluminum alloy precursor powder. Using vacuum hot pressing sintering, the alumina hollow microspheres + aluminum alloy precursor powder are evenly put into the mold, the sintering temperature is controlled at 630°C, the holding time is 3h, and the pressure is 1MPa to obtain a uniform porosity of about 30%. Porous aluminum alloy with spherical pores (the deviation between the actual porosity and the designed porosity is less than 5%). Taking the product obtained in Example 1 as the processing object, it was subjected to a compression performance test; when the compressive strength reached ...

Embodiment 2

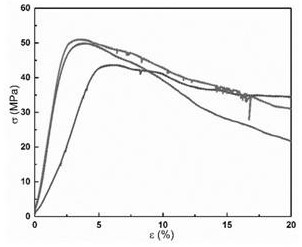

[0042] Alumina hollow microspheres with an outer diameter of 100 μm and a wall thickness of 5 μm were used as pore-forming agents. Under argon protection, the alumina hollow microspheres and 18 μm 2024 aluminum alloy powder were mixed in a volume ratio of 1:1 in a glove box. Put it into a closed container, and then fully mix the materials to obtain uniformly mixed alumina hollow microspheres + aluminum alloy precursor powder. Vacuum hot pressing sintering is used to uniformly put alumina hollow microspheres + aluminum alloy precursor powder into the mold, control the sintering temperature to 600°C, hold time for 2h, and pressure at 5MPa to obtain a uniform porosity of about 20%. Porous aluminum alloy with spherical pores (the deviation between the actual porosity and the designed porosity is less than 4%).

[0043]The product developed in Example 2 can be used for energy-absorbing parts of vehicles.

Embodiment 3

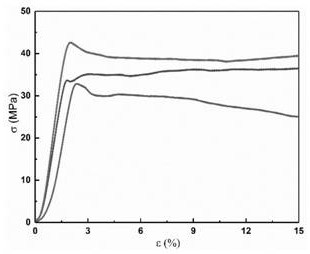

[0045] Alumina hollow microspheres with an outer diameter of 50 μm and a wall thickness of 3 μm were used as pore-forming agents. Under argon protection, the alumina hollow microspheres and 10 μm 2A12 aluminum alloy powder were mixed in a volume ratio of 2:3 in a glove box. Put it into a closed container, and then fully mix the materials to obtain uniformly mixed alumina hollow microspheres + aluminum alloy precursor powder. Using vacuum hot pressing sintering, put alumina hollow microspheres + aluminum alloy precursor powder evenly into the mold, control the sintering temperature to 620°C, hold time for 2h, and pressure at 2MPa to obtain a uniform porosity of about 50%. Porous aluminum alloy with spherical pores (the deviation between the actual porosity and the designed porosity is less than 5%).

[0046] The product developed in Example 3 can be used for energy-absorbing components of vehicles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com