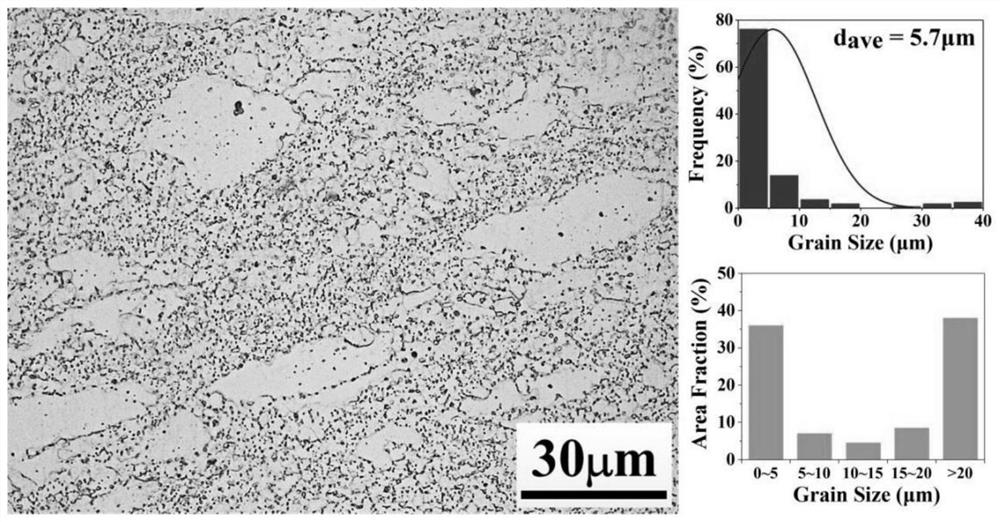

Method for preparing high-strength and high-plasticity magnesium alloy with mixcrystal structure

A magnesium alloy and mixed crystal technology, which is applied in the field of preparing magnesium alloy with high-strength plastic mixed crystal structure, can solve the problems of low plasticity and limited industrial application of high-strength magnesium alloys, and achieve the goal of increasing strength, improving work hardening ability, and improving deformation ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

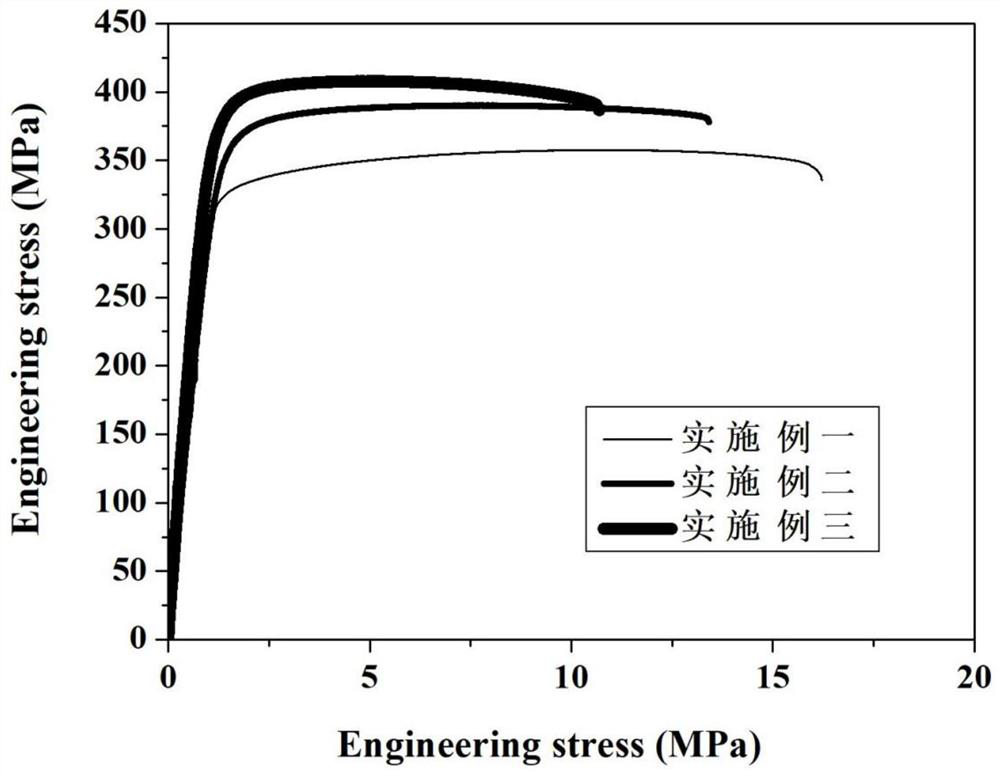

Embodiment 1

[0019] A method for preparing a high-strength plastic mixed crystal structure magnesium alloy, characterized in that it comprises the steps of:

[0020] A. Homogenize the Mg alloy extruded plate, including: charging with the furnace, heating from room temperature to 420°C within 60min, keeping it warm for 20h, and then quenching with 30°C water; the magnesium alloy extruded The press plate includes the following components in mass percentage: Al 6.3%, Zn 0.7%, Sn 0.9%, Mn 0.3%, and the balance is Mg and unavoidable impurities.

[0021] B. The Mg alloy plate obtained in step A is subjected to equal-diameter angular extrusion; the specific operation of said equal-diameter angular extrusion is: according to the path Bc, first extrude at an extrusion temperature of 300 ° C, and the extrusion pass is 1 times; followed by holding at 250°C for 60 minutes, and then extruding at an extrusion temperature of 250°C, one extrusion pass; then holding at 250°C for 90 minutes. said B c Path...

Embodiment 2

[0025] A method for preparing a high-strength plastic mixed crystal structure magnesium alloy, characterized in that it comprises the steps of:

[0026] A. Homogenize the Mg alloy extruded plate, including: charging with the furnace, raising the temperature from room temperature to 430°C within 60min, keeping it warm for 20h, and then quenching with 30°C water; the magnesium alloy extruded The press plate includes the following components in mass percentage: Al 6.1%, Zn 0.8%, Sn 0.8%, Mn 0.2%, and the balance is Mg and unavoidable impurities.

[0027] B, the Mg alloy plate that step A obtains is carried out equal path angle extrusion; The concrete operation of described equal path angle extrusion is: press B c The path is to extrude at an extrusion temperature of 300°C for one extrusion pass; then hold at 250°C for 60 minutes, and then extrude at an extrusion temperature of 250°C for one extrusion pass; then Insulate at 250°C for 100 minutes. said B c Path: After each pass ...

Embodiment 3

[0031] A method for preparing a high-strength plastic mixed crystal structure magnesium alloy, characterized in that it comprises the steps of:

[0032] A. Homogenize the Mg alloy extruded plate, including: charging with the furnace, heating from room temperature to 440°C within 60min, keeping it warm for 21h, and then quenching with 30°C water; the magnesium alloy extruded The press plate includes the following components in mass percentage: Al 6%, Zn 0.7%, Sn 0.9%, Mn 0.3%, and the balance is Mg and unavoidable impurities.

[0033] B, the Mg alloy plate that step A obtains is carried out equal path angle extrusion; The concrete operation of described equal path angle extrusion is: press B c The path is to extrude at an extrusion temperature of 300°C for one extrusion pass; then hold at 250°C for 60 minutes, and then extrude at an extrusion temperature of 250°C for one extrusion pass; then Insulate at 250°C for 85 minutes. said B c Path: After each pass of extrusion, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com