Nano-osmosis washing-free technology for polyester fabric

A non-washing and fabric technology, applied in the field of printing and dyeing, which can solve the problems of dye diffusion and inaccurate printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

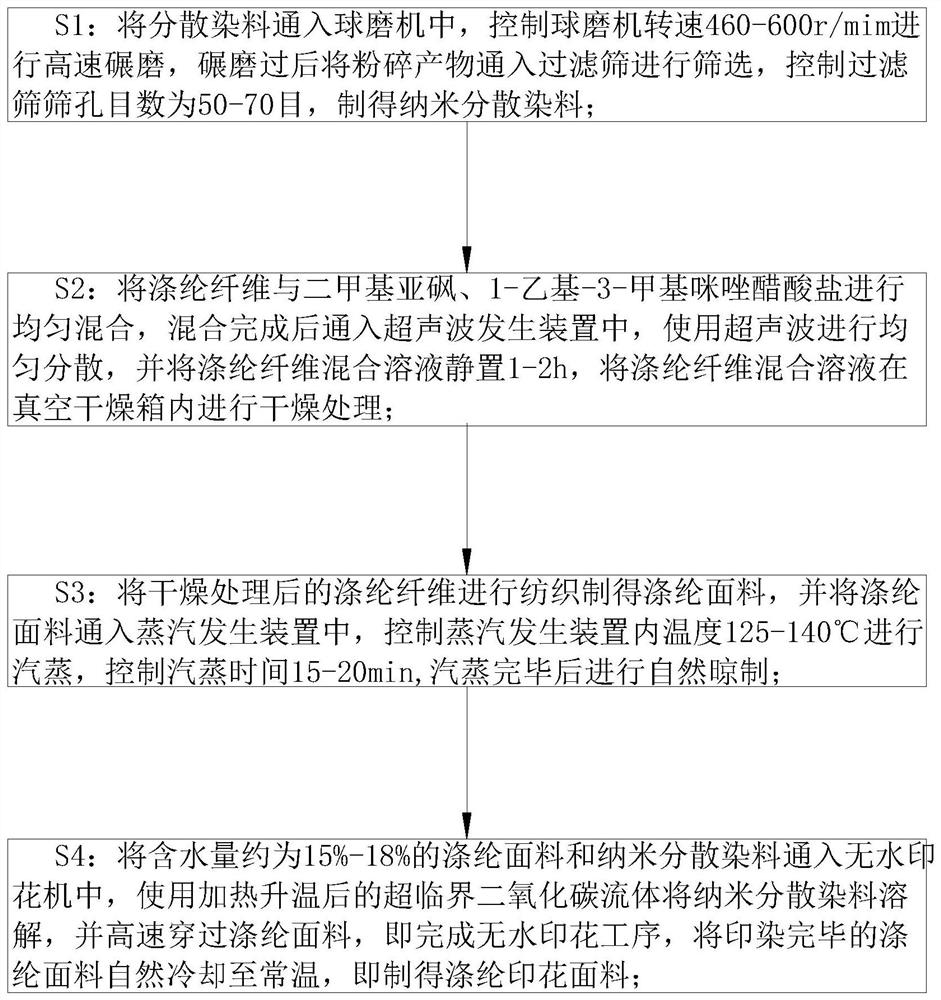

Method used

Image

Examples

Embodiment approach

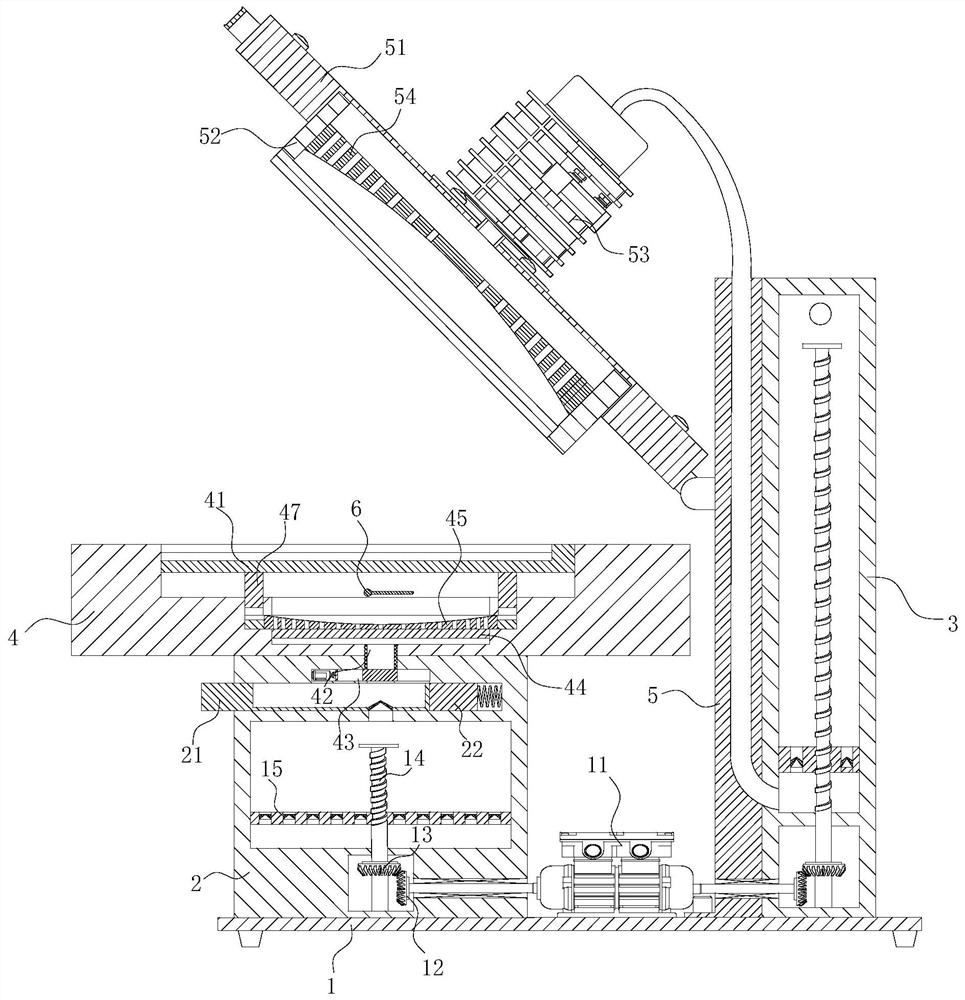

[0036] As an embodiment of the present invention, the first through groove is designed in a "ten" shape; the end of the first through groove close to the conduction pipe 42 is fixedly connected with a deflector 44; the deflector 44 is provided with Evenly distributed first diversion holes; a rotating plate 45 is rotatably connected in the first through groove; second evenly distributed diversion holes are provided on the rotating plate 45; the circumferential surface of the rotating plate 45 is fixedly connected There are evenly distributed pressing blocks 46; the pressing blocks 46 are elastically connected to the side wall of the first through groove; one side of the pressing block 46 is designed to be inclined; the pressing plate 41 is fixed on the side close to the first through groove. Evenly distributed pressing rods 47 are connected; the pressing rods 47 all extend into the first through groove and correspond to the pressing blocks 46 one by one; in the initial state, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com