Process for processing TGV by combining femtosecond laser with HF wet etching

A femtosecond laser and wet etching technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as poor processing rate, inability to withstand huge stress, and weakened strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

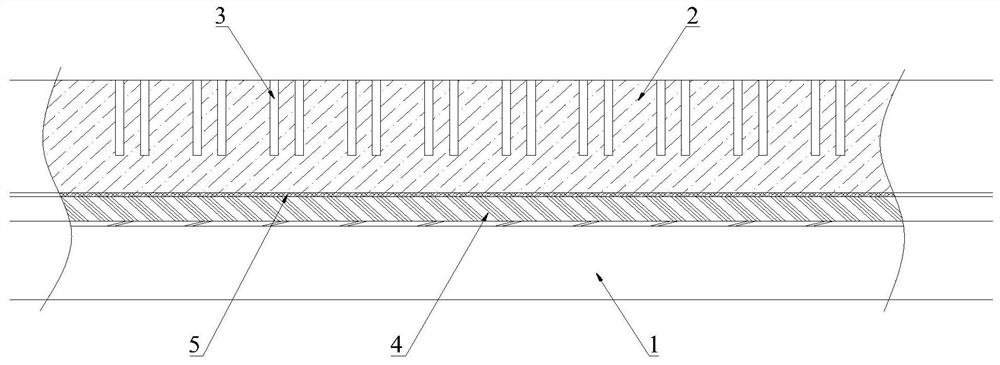

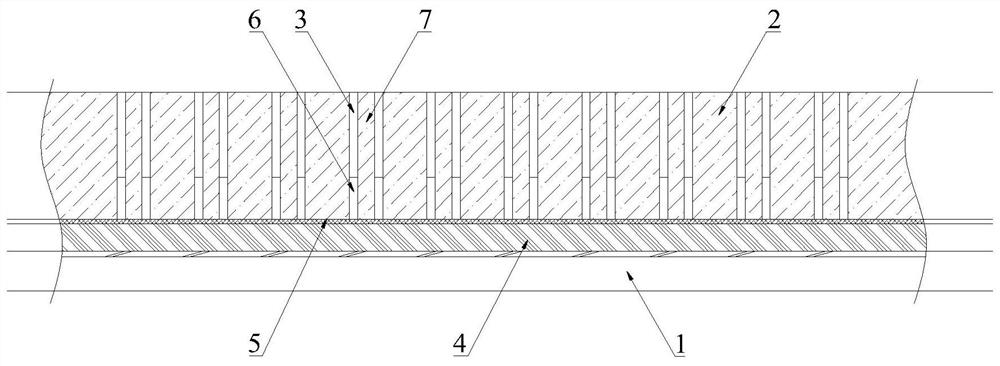

[0035] A femtosecond laser combined with HF wet etching process TGV process, comprising the following steps:

[0036] S1. Permanently bond the front of the wafer to the glass carrier, then turn it over to the glass surface, scan the surrounding area of the hole on the glass carrier with a femtosecond laser, deconstruct the glass bond in this area, and use HF to etch the area to form a circular etching hole , the depth of the etched hole is 85% of the thickness of the glass substrate, the central wavelength of the femtosecond laser is 810nm, and the pulse width is 320×10 -15 s, the repetition frequency is 100kHz;

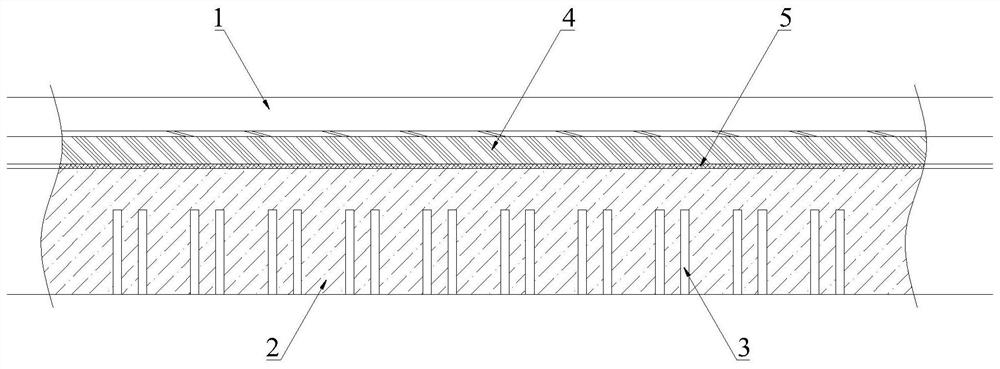

[0037] S2. Turn over to the wafer side, and perform thinning and component engineering on the back side of the wafer;

[0038] S3, turn over to the glass surface again, and use HF etching to perform the second pattern etching process until the perforation is completed;

[0039] S4. Use laser to debond the middle island glass area, then put the wafer and glass car...

Embodiment 2

[0042] A femtosecond laser combined with HF wet etching process TGV process, comprising the following steps:

[0043] S1. Temporarily bond the front of the wafer to a glass carrier, then turn it over to the glass surface, scan the surrounding area of the hole on the glass carrier with a femtosecond laser, deconstruct the glass bond in this area, and use HF to etch this area to form a circular etching hole. , the depth of the etched hole is 80% of the thickness of the glass substrate, the central wavelength of the femtosecond laser is 780nm, and the pulse width is 92×10 -15 s, the repetition frequency is 85kHz;

[0044] S2. Flip over to the wafer side, and perform thinning and component engineering on the back side of the wafer;

[0045] S3, turn over to the glass surface again, and use HF etching to perform the second pattern etching process until the perforation is completed;

[0046]S4. Use laser to debond the middle island glass area, then put the wafer and glass carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com