Method for avoiding blackening of negative electrode pin-flexible connection of lithium ion battery

A lithium-ion battery and soft connection technology, applied in the field of lithium batteries, can solve the problems of not considering the influence of corrosion and blackening on electrical properties, affecting the performance and cycle life of square lithium-ion batteries, and aggravating the problem of corrosion and blackening, which is conducive to automation. , low cost, avoid the effect of corrosion and blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

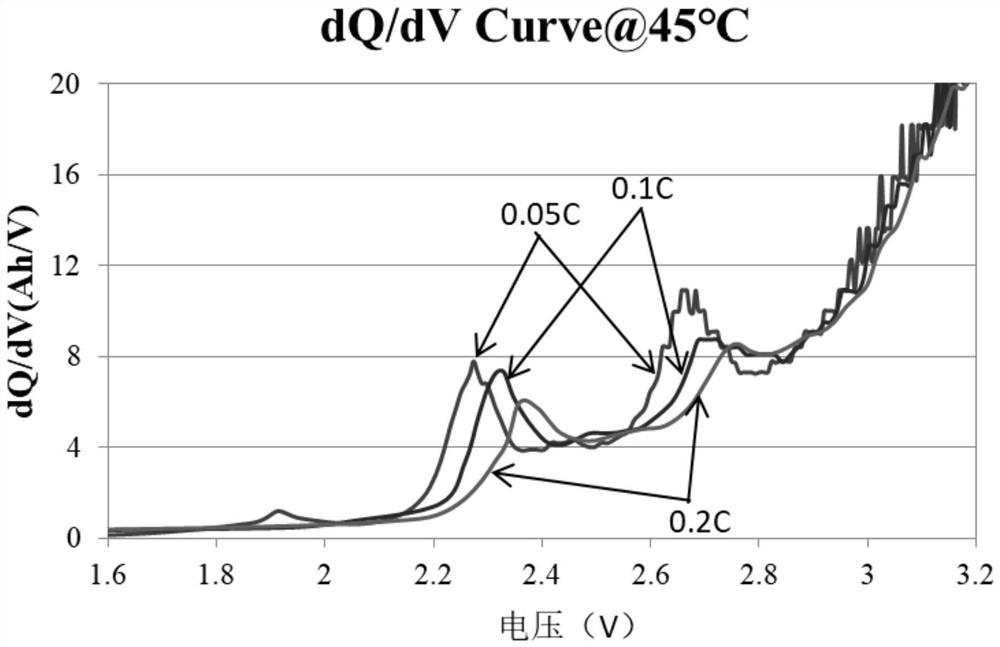

[0039] This embodiment uses a square lithium-ion battery, and its dQ / dV variation curve with voltage is as follows figure 1 shown by figure 1 It can be seen that as the charge rate decreases, the position of the film-forming reaction peak shifts to the left, and the peak intensity increases, and an obvious film-forming reaction peak appears at 1.9V-2.0V. Therefore, in order to reduce the impact of the pre-charging process on the formation The film-forming reaction will have adverse effects. This solution adopts a high-current, short-time charging mode;

[0040] In this embodiment, the method for avoiding the blackening of the negative electrode pin of the square lithium-ion battery-soft connection includes:

[0041] (1) After the square lithium-ion battery is filled with liquid, charge it at 0.5C for 60s at a constant current;

[0042](2) Stand the prismatic lithium-ion battery at 45°C for 24 hours after pre-charging;

[0043] (3) Perform negative pressure formation at 45° ...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that the method includes the following steps:

[0048] (1) After the square lithium-ion battery is filled with liquid, charge it at a constant current for 30s at 1C;

[0049] (2) Stand the prismatic lithium-ion battery at 45°C for 24 hours after pre-charging;

[0050] (3) Perform negative pressure formation at 45° C. on the square lithium-ion battery after standing;

[0051] (4) Perform rehydration, aging, sealing and volume separation on the square lithium-ion battery after negative pressure formation, to obtain the square lithium-ion battery.

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 is that the method includes the following steps:

[0054] (1) After the square lithium-ion battery is filled with liquid, charge it at 0.65C for 50s at a constant current;

[0055] (2) Stand the prismatic lithium-ion battery at 45°C for 24 hours after pre-charging;

[0056] (3) Perform negative pressure formation at 45° C. on the square lithium-ion battery after standing;

[0057] (4) Perform rehydration, aging, sealing and volume separation on the square lithium-ion battery after negative pressure formation, to obtain the square lithium-ion battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com