Preparation method of efficient special-shaped bamboo scrimber

A technology for reconstituting bamboo materials and bamboo materials, which is applied in the directions of impregnating wood, manufacturing tools, and wood impregnation, etc., can solve the problem of uneven softening effect of steam heating bamboo materials, and single structure and form and insufficient depth of flat plate group blank hot-pressed glued products. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

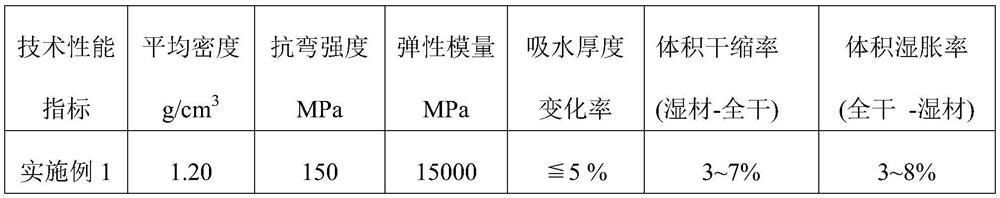

Embodiment 1

[0020] The specific operation steps of the preparation method of a kind of high-efficiency special-shaped bamboo recombined wood of the present invention are as follows:

[0021] (1) Bamboo lye dipping and cooking treatment

[0022] The fresh raw bamboo is prepared by special equipment, and then the bamboo is soaked in NaOH dilute alkali solution with a mass ratio concentration of 2%. After impregnating phenolic resin or other amino resin glue and drying treatment, the trace amount of lye remaining in the bamboo is conducive to the curing of thermosetting phenolic resin in the next step; the washing liquid is recycled as low-concentration lye to ensure environmental protection during the production process.

[0023] (2) Bamboo impregnated with glue and dried

[0024] Use impregnated phenolic resin or other amino resin glue as the thermosetting resin, and the solid content of the impregnated resin is 15%. The bamboo impregnation process usually adopts the direct impregnation m...

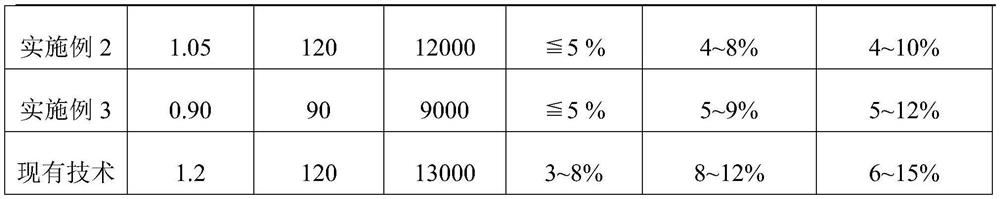

Embodiment 2

[0028] A kind of preparation method of high-efficiency special-shaped bamboo recombined timber of the present invention concrete operation steps are as follows:

[0029] (1) Bamboo lye dipping and cooking treatment

[0030] The fresh raw bamboo is prepared by special equipment, and then the bamboo is soaked and cooked in NaOH dilute lye with a mass ratio concentration of 3%. The technical parameters of cooking and softening are pressure 0.35Mpa, temperature 120°C, time 135min, and then soaking and cleaning for about 7min After impregnation with phenolic resin or other amino resin glue and drying treatment, the trace amount of lye in the bamboo is conducive to the curing of the thermosetting phenolic resin; the lotion is used as a low-concentration lye for recycling to ensure environmental protection during the production process.

[0031] (2) Bamboo impregnated with glue and dried

[0032] Use impregnated phenolic resin or other amino resin glue as the thermosetting resin, an...

Embodiment 3

[0036] The specific operation steps of the preparation method of a kind of high-efficiency special-shaped bamboo recombined wood of the present invention are as follows:

[0037] (1) Bamboo lye dipping and cooking treatment

[0038] The fresh raw bamboo is prepared by special equipment, and then the bamboo is soaked and cooked in NaOH dilute lye with a mass ratio concentration of 4%. Impregnating phenolic resin or other amino resin glue and drying treatment, the small amount of lye in bamboo is conducive to the curing of thermosetting phenolic resin; the lotion is used as a low-concentration lye for recycling to ensure environmental protection during the production process.

[0039] (2) Bamboo impregnated with glue and dried

[0040] Use impregnated phenolic resin or other amino resin glue as the thermosetting resin, and the solid content of the impregnated resin is 35%. The bamboo impregnation process usually adopts the direct impregnation method at room temperature, and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com