Efficient molybdenum removal vertical subsurface flow constructed wetland purification device

A technology of vertical underflow and constructed wetlands, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

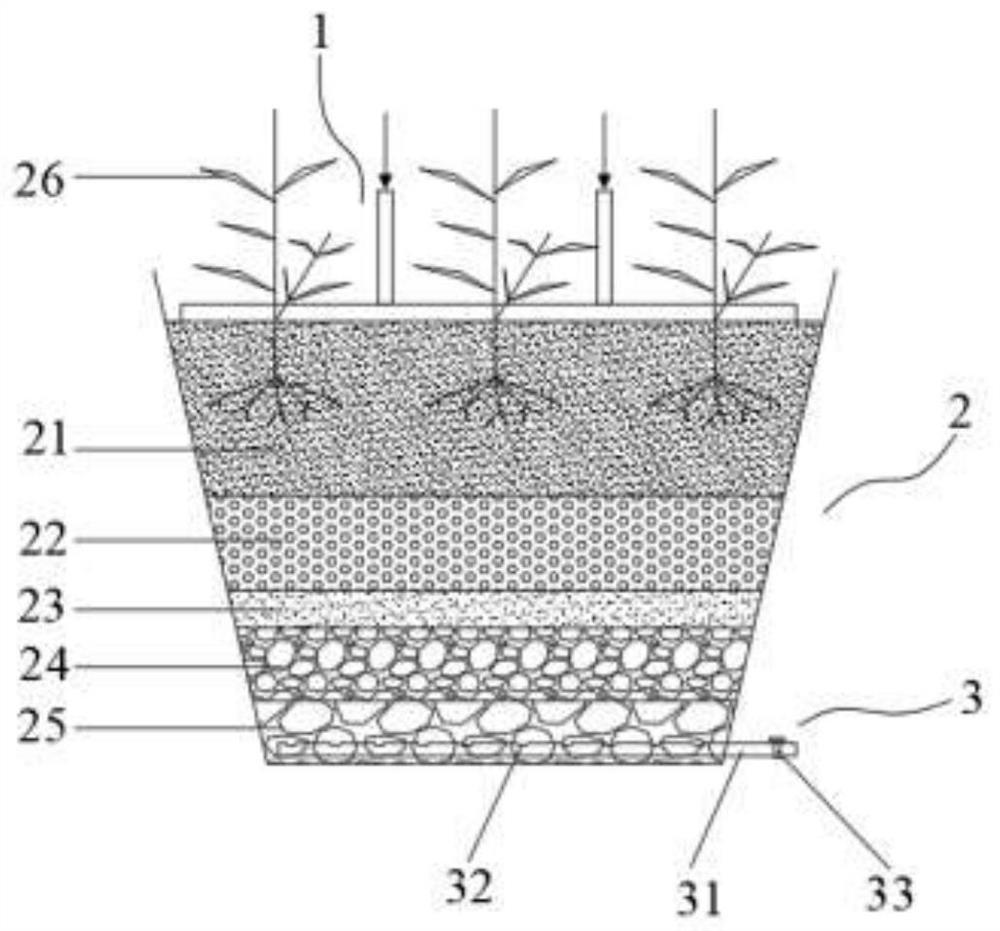

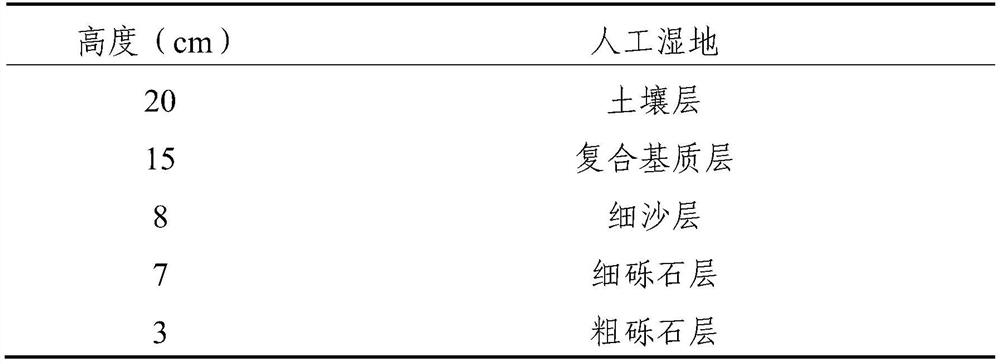

[0027] This embodiment provides a high-efficiency molybdenum removal vertical underflow artificial wetland purification device suitable for molybdenum tailings non-point source sewage treatment, such as figure 1 As shown, the purification device includes a water inlet mechanism 1, a purification zone 2, and a water outlet mechanism 3. The purification zone 2 includes a soil layer 21, a composite matrix layer 22, a fine sand layer 23, and a supporting layer from top to bottom.

[0028] Soil layer 21 is planted with cattails, and the planting density of cattails is 26 plants / m 2 . The composite matrix layer 22 is a combined matrix of modified cinder and pyrite, and the supporting layer includes a fine gravel layer 24 and a coarse gravel layer 25 from top to bottom.

[0029]A water inlet mechanism 1 is arranged above the purification area 2, and a water outlet mechanism 3 is arranged at the bottom of the purification area 2. The water intake mechanism 1 adopts intermittent wate...

Embodiment 2

[0034] Same as Example 1, the difference is that the composite matrix layer is soil.

Embodiment 3

[0036] Same as Example 1, the difference is that the composite matrix layer is modified cinder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com