Online concentrated continuous flow modular sludge storage tank

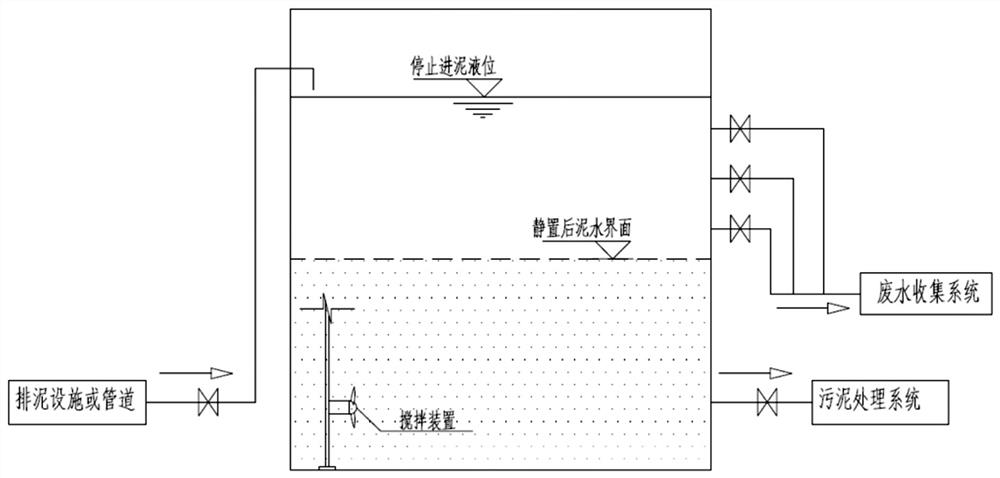

A mud storage tank, modular technology, applied in the field of water treatment, can solve the problems of sludge return to muddy, long residence time, large equipment loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

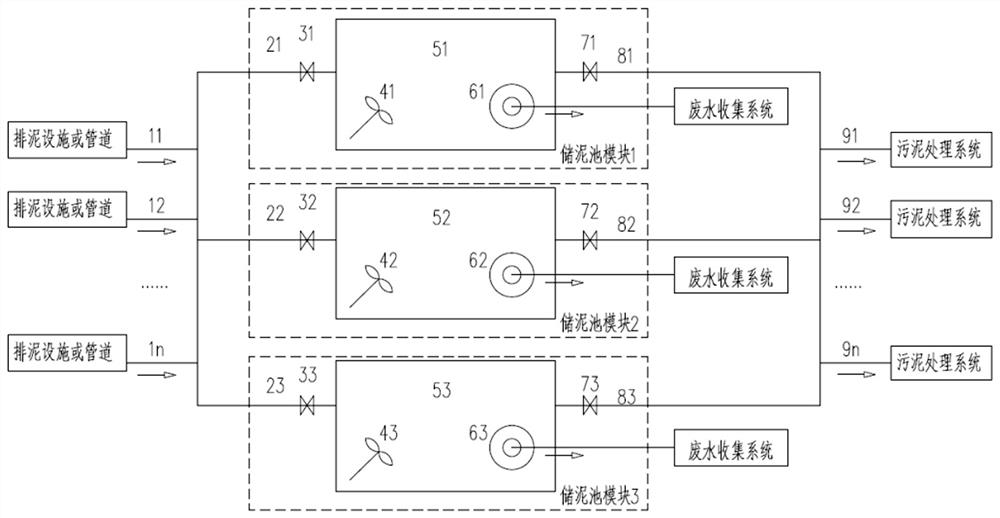

Embodiment 1

[0041] Embodiment 1 mode of operation (see the attached schematic diagram for details figure 2 ):

[0042] period 1 period 2 period 3 Mud storage module 1 Mud mode concentrated mode mud mode Mud storage module 2 mud mode Mud mode concentrated mode Mud storage module 3 concentrated mode mud mode Mud mode

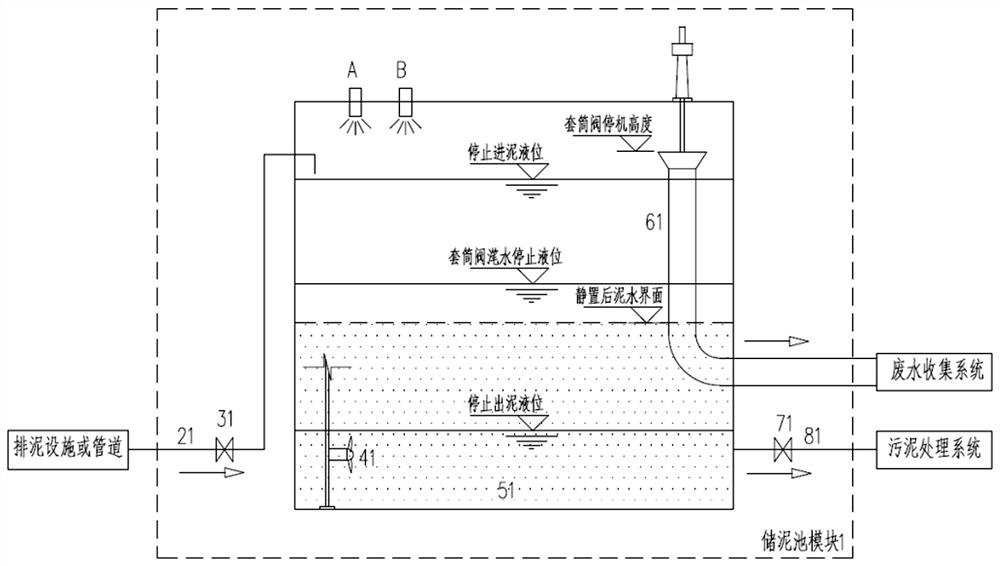

Embodiment 2

[0043] Embodiment 2 mode of operation (see the attached schematic diagram for details Figure 4 ):

[0044] period 1 period 2 period 3 period 4 Mud storage module 1 Mud mode concentrated mode Mud mode mud mode Mud storage module 2 mud mode Mud mode concentrated mode Mud mode Mud storage module 3 Mud mode mud mode Mud mode concentrated mode Mud storage module 4 concentrated mode Mud mode mud mode Mud mode

Embodiment 3

[0045] Embodiment 3 mode of operation (plan schematic diagram sees attached Figure 5 ):

[0046] period 1 period 2 period 3 period 4 period 5 Mud storage module 1 Mud mode concentrated mode Mud mode concentrated mode mud mode Mud storage module 2 mud mode Mud mode concentrated mode Mud mode concentrated mode Mud storage module 3 concentrated mode mud mode Mud mode concentrated mode Mud mode Mud storage module 4 Mud mode concentrated mode mud mode Mud mode concentrated mode Mud storage module 5 concentrated mode Mud mode concentrated mode mud mode Mud mode

[0047] It should be noted that the embodiments of the device and method are not limited to the above three embodiments. If there are more storage pools, the effect of concentration and efficiency improvement will be better, but it also requires higher cost and more Complex control logic.

[0048] Still take embodiment 1,2,3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com