Aromatic sulfone composition as well as preparation method and application thereof

A kind of technology of aromatic sulfone and composition, applied in the field of aromatic sulfone composition and preparation thereof, and can solve problems such as difficult and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

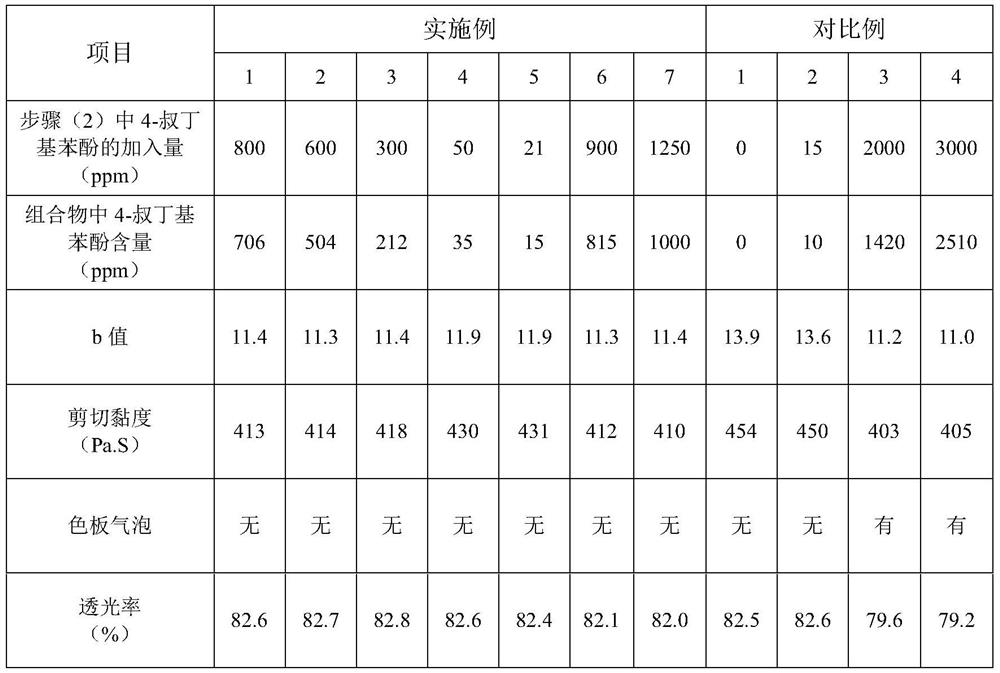

Embodiment 1~6 and comparative example 1~4

[0045] This embodiment and comparative example provide a series of polyphenylsulfone compositions. Its preparation process is as follows:

[0046] (1) Preparation of polyphenylsulfone polymer

[0047] Quantitatively add 36kg sulfolane, 8.79kg 4,4'-dichlorodiphenyl sulfone and 5.59kg 4,4'-biphenyldiphenol into a 100L reaction kettle protected by high-purity nitrogen, stir to raise the temperature and add 33kg sodium carbonate and 3kg di For toluene, use the solution polycondensation method, keep it at 180-220°C for 5 hours, during the reaction process, the xylene will continuously discharge the reaction water through azeotropy, until no water is discharged, the salt-forming reaction is over, and the xylene is evaporated. Afterwards, the temperature of the reaction system was raised to 235° C. and kept for 3 h. Stop stirring and heating, precipitate the above-mentioned polymer material into strips in water, pulverize it with a crusher to obtain a powder material, boil it with ...

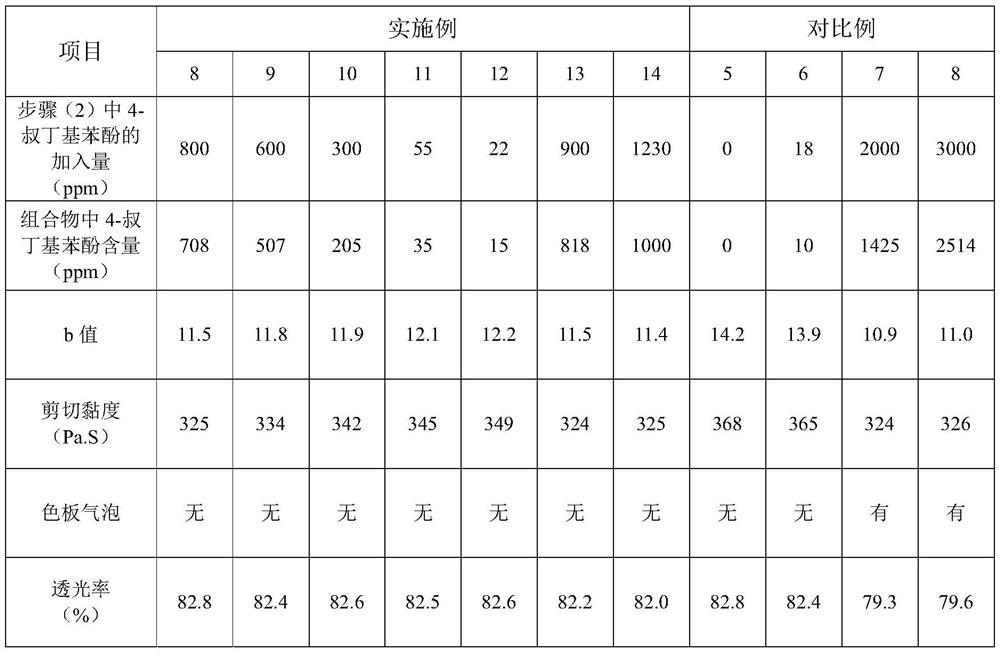

Embodiment 8~14 and comparative example 5~8

[0053] This embodiment and comparative example provide a series of polyethersulfone compositions. Its preparation process is as follows:

[0054] (1) Preparation of polyethersulfone polymer

[0055] Quantitatively add 36kg sulfolane, 8.79kg 4,4'-dichlorodiphenylsulfone and 7.51kg 4,4'-dihydroxydiphenylsulfone into a 100L reaction kettle protected by high-purity nitrogen, stir and add 33kg sodium carbonate and 3kg Xylene, using the solution polycondensation method, kept at 180-220°C for 5 hours, during the reaction process, the xylene was continuously discharged through azeotropic reaction water until no water was discharged, the salt-forming reaction was completed, and the xylene was evaporated. Afterwards, the temperature of the reaction system was raised to 235° C. and kept for 3 h. Stop stirring and heating, precipitate the above-mentioned polymer material into strips in water, pulverize it with a crusher to obtain a powder material, boil it with deionized water for 1 hou...

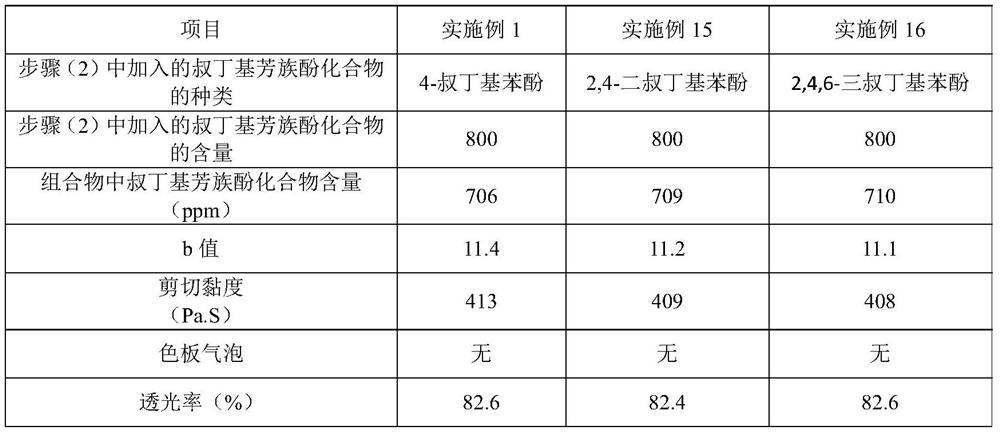

Embodiment 14

[0061] This embodiment provides an aromatic sulfone composition. In the preparation process, except that the selected tert-butyl aromatic phenol compound is 2,4-di-tert-butylphenol, the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com